Description

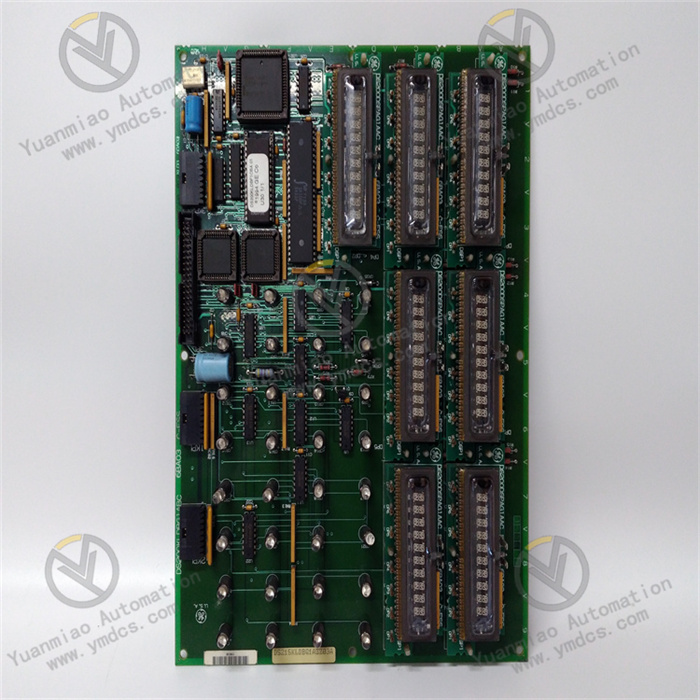

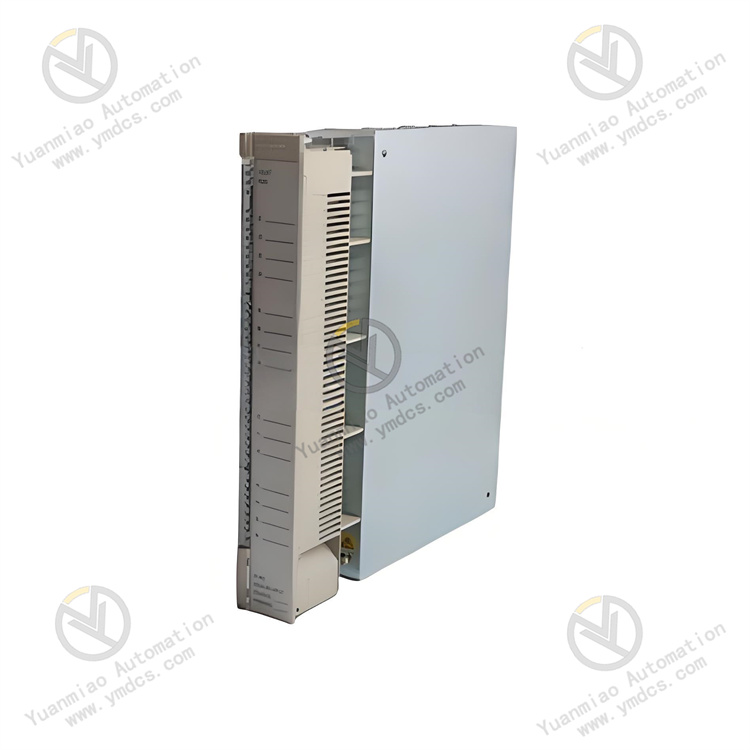

The ABB PPD512A10 - 15000 3BHE040375R1023 is an excitation control system, mainly composed of two main parts: the excitation power unit and the excitation regulator. Advanced control technology: By adopting the advanced PID control algorithm, it can quickly respond to the operating status of the motor, achieve precise excitation control, and ensure the normal operation of the motor and the generator. Stable and reliable performance: Using high-quality electronic components and materials, and having gone through strict testing and verification, it can maintain stable performance in various harsh environments. Convenient configuration and operation: It provides easy-to-use configuration software and interfaces. Users can configure and adjust it according to their needs, and it can be quickly deployed and integrated. Wide application range: It is suitable for various types of industrial motors and generators, such as alternating current motors, direct current motors, synchronous motors, asynchronous motors, etc. It has good compatibility and can be integrated with existing control systems to achieve efficient control and monitoring. The static excitation system to which this system belongs controls the excitation current through a thyristor rectifier bridge, and then regulates the terminal voltage and reactive power of the synchronous generator. The entire system can be divided into four main parts: the excitation transformer, two sets of independent excitation regulators, the thyristor rectifier unit, the excitation starting unit, and the de-excitation unit.

General Installation Steps of ABB PPD512A10 - 15000 3BHE040375R1023:

1. Preparation before Installation

Confirm the Model Specifications: Check whether the model and parameters of PPD512A10 - 15000 are correct according to the equipment list and design requirements, and ensure that they are in line with the actual application needs, including parameters such as rated voltage, current, and power.

Prepare Tools and Materials: Prepare the tools required for installation, such as screwdrivers, wrenches, cable cutters, crimping pliers, etc., as well as installation materials, such as bolts, nuts, gaskets, cables, insulating materials, etc.

Inspect the Installation Environment: Select a suitable installation location, which should be away from harmful environments such as water, humidity, high temperature, corrosives, and strong electromagnetic interference sources. Ensure that there is enough space around for equipment installation, debugging, and maintenance, and it is convenient for heat dissipation. At the same time, confirm that the ground or support at the installation location can bear the weight of the equipment.

Cut off the Power Supply: Before installation, be sure to cut off the relevant power supply and ensure that the power supply will not be accidentally turned on during the installation process to ensure personal safety and equipment safety.

2. Install the Main Body of the Equipment

Fix the Installation Bracket or Base: If the equipment needs to be installed on a bracket or base, use bolts or screws to firmly fix the bracket or base at the selected installation location, ensuring its stability and the ability to withstand the vibration and stress that may occur during the operation of the equipment.

Install the Excitation Control System: Place the PPD512A10 - 15000 excitation control system on the installation bracket or base, and use bolts or nuts to fix it tightly, ensuring that the equipment is installed firmly and will not loosen due to vibration or other factors.

3. Connect the Cables Connect the Power Cable: Connect the power cable of the appropriate specification to the power input terminal of PPD512A10 - 15000 according to the rated voltage and power requirements of the equipment. Ensure that the cable connection is firm and in good contact, avoiding looseness or poor connection. Also, carry out appropriate insulation treatment and fixation of the cable to prevent the cable from being pulled or worn by external forces. Connect the Control Cable: Connect the control cable to the corresponding control terminals according to the control requirements of the system, such as the signal transmission cable between the excitation regulator and other equipment (such as generators, protection devices, etc.). When connecting, pay attention to the good grounding of the shielding layer of the cable to reduce the influence of electromagnetic interference on the control signal. Connect the Generator Field Cable: Connect the insulated generator field cable to the output terminal of the excitation system and the terminal of the generator's field winding, ensuring a reliable connection and good insulation performance to prevent the leakage of excitation current and short-circuit faults. 4. Grounding Connection: To ensure the safe operation of the equipment and personal safety, connect the grounding terminal of PPD512A10 - 15000 to the grounding grid or grounding electrode through a dedicated grounding wire. The grounding resistance should meet the technical requirements of the equipment. Generally, the grounding resistance is required to be no greater than the specified value (such as 4Ω or 10Ω, etc.) to ensure that the current can safely flow into the ground when the equipment fails. 5. Inspection and Testing Appearance Inspection: After the installation is completed, conduct an appearance inspection of the equipment to check whether all components are installed firmly, whether the cable connections are correct and neat, whether the grounding is reliable, and whether there are any loose, damaged, or missing components. Electrical Connection Inspection: Use tools such as a multimeter or an insulation resistance tester to check the insulation resistance between the power input and output terminals and between each cable, which should meet the insulation requirements of the equipment. At the same time, check the contact resistance of each electrical connection point to ensure good contact. Function Testing: Before powering on, confirm again whether the parameter settings of the equipment are correct, and then turn on the power supply to conduct function testing on the excitation control system. For example, check whether the excitation regulator can work normally, whether it can adjust the excitation current according to the set value, and whether the terminal voltage and reactive power of the generator can be effectively controlled, etc. Some simulated fault tests can also be carried out to check whether the protection function of the equipment is normal.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB