Description

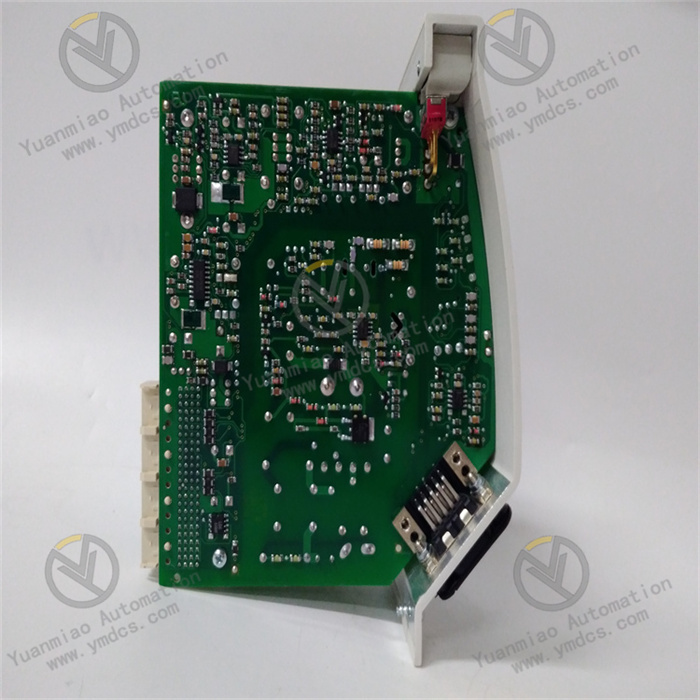

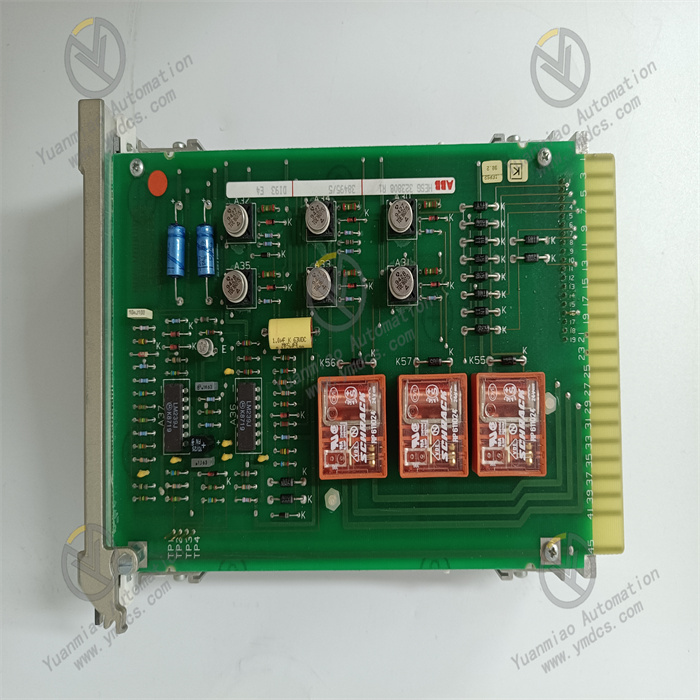

ABB SA811F 3BDH000013R1 is a module used in the field of industrial automation and is usually part of a distributed control system (DCS). Its working principle is as follows: Signal Acquisition and Processing Analog Input Processing: This module is equipped with analog input channels and can receive analog signals output by various field sensors (such as temperature, pressure, flow sensors, etc.). These analog signals are generally continuously varying voltage or current signals. The module converts the input analog signals into digital signals through an analog-to-digital converter (ADC) for subsequent processing and analysis. Digital Input Processing: For digital input signals, the module performs level detection and status reading. Digital input signals usually come from devices such as switches and relay contacts and represent two states, such as on/off and high/low level. The module converts this status information into digital signals that can be recognized by a computer and stores them in the corresponding registers. Control Operation and Logic Processing Program-based Operation: The module internally stores control programs written by users. These programs define various control algorithms and logic rules. Based on the collected input signals and preset control strategies, the module performs mathematical operations and logical judgments according to the instructions in the program. For example, according to the signals input by the temperature sensor, the control quantity to be output is calculated through a PID (Proportional-Integral-Differential) control algorithm to adjust the temperature around the set value. Logic Function Realization: It can realize various logic functions, such as AND, OR, NOT and other logical operations, which are used to combine and judge multiple input signals to determine the output status. For example, a certain output action is triggered only when multiple conditions are simultaneously met. This logical judgment ability enables the module to flexibly adapt to different industrial control scenarios.

Signal Output and Control Execution Analog Output: After operation and processing, if an analog signal needs to be output to control field devices, such as the opening of a regulating valve and the frequency of an inverter, the module converts the digital signal into the corresponding analog voltage or current signal through a digital-to-analog converter (DAC) and outputs it to the field device to achieve continuous regulation and control of the device. Digital Output: For digital output, according to the execution result of the program, the module converts the digital signal status in the register into an actual physical signal through the output circuit, such as energizing or de-energizing a relay coil, thereby controlling the switch status of external devices, such as the start/stop of a motor and the opening/closing of a valve. Communication Function Communication with Other Devices: The SA811F module usually has communication interfaces and can communicate with other modules, controllers or upper computers. Through the communication network, it can receive control instructions, parameter settings and other information from the upper computer, and at the same time upload the collected data and status information to the upper computer to achieve information interaction and collaborative work of the entire industrial control system. Common communication protocols include Profibus, Modbus, etc., and different protocols are applicable to different industrial network environments and device connection requirements. Diagnosis and Self-protection Fault Diagnosis: The module has a self-diagnosis function and can monitor its own working status in real time. For example, it checks whether the power supply voltage is normal, whether there are faults in the internal circuit, and whether the communication is normal. Once a fault is detected, the module generates the corresponding fault code and reports the fault information to the upper computer through indicator lights or communication methods so that maintenance personnel can discover and deal with the problem in time. Self-protection Mechanism: In order to prevent the module from being damaged under abnormal conditions or affecting the entire system, it also has a self-protection mechanism. For example, when it detects that the input signal exceeds the specified range, there is a power failure or internal overheating, the module will automatically take corresponding protection measures, such as stopping the output and entering the safety mode, to ensure the stability and safety of the system.

Features and Functions High-precision Measurement: It can accurately measure relevant physical quantities and provide accurate data for the control system. For example, it can accurately measure electrical parameters such as voltage and current to ensure the stable operation and precise control of the system. Reliable Signal Processing: It has good signal processing capabilities. It can filter, amplify and process the input signals to improve the signal quality, reduce the influence of interference, and ensure the reliability and stability of the system. Multiple Communication Interfaces: It supports multiple communication protocols and interface methods, such as Profibus, Modbus, etc., which is convenient for communication and integration with other devices. It can be flexibly connected to different automation control systems to achieve information interaction and collaborative work between devices. Wide Operating Range: It can work stably under a wide range of environmental conditions such as temperature and humidity. It can adapt to different industrial field environments. For example, it can operate normally in environments with high temperature, high humidity or dust and vibration, and has strong environmental adaptability. Technical Parameters Input Voltage Range: It may support multiple input voltages, such as 24V DC ±10%, etc., to adapt to different power supply systems. Measurement Accuracy: For example, the current measurement accuracy can reach ±0.1% FS (full scale), and the voltage measurement accuracy can reach ±0.2% FS, etc. The specific accuracy index depends on the actual measurement range and requirements. Communication Rate: If it supports Profibus communication, the communication rate may be selectable from 9.6Kbps to 12Mbps; if it supports Modbus communication, the baud rate may be selectable from 1200 to 115200bps. Operating Temperature Range: Generally, it is from -25°C to +70°C, meeting the temperature requirements of most industrial environments.

Common Faults and Solutions Communication Fault Fault Phenomenon: The module cannot communicate normally with other devices, or communication data has errors, losses, etc. Solution: Check whether the communication cable is well connected, and whether there is any damage or open circuit; confirm whether the communication interface is damaged; check whether the communication parameter settings of the module and the communicating device, such as baud rate, data bits, stop bits, parity bits, etc., are consistent; check whether the network configuration is correct and whether relevant network devices (such as switches, etc.) are working properly. Inaccurate Measurement Fault Phenomenon: There is a large deviation between the measured value and the actual value. Solution: Check whether the sensor or other signal sources are working properly and whether calibration is required; confirm whether the range setting of the module matches the actual measurement range; check whether there is interference in the measurement loop, and measures such as shielding and filtering can be taken to eliminate the interference. Power Supply Fault Fault Phenomenon: The indicator light of the module does not light up, or the module cannot start and work normally. Solution: Check whether the power supply is normal and measure whether the input power supply voltage is within the specified range; check whether the power connection cable is well connected, and whether there is any looseness or open circuit; if the power supply voltage is abnormal, check whether the power supply device is faulty, and the power module may need to be replaced if necessary.