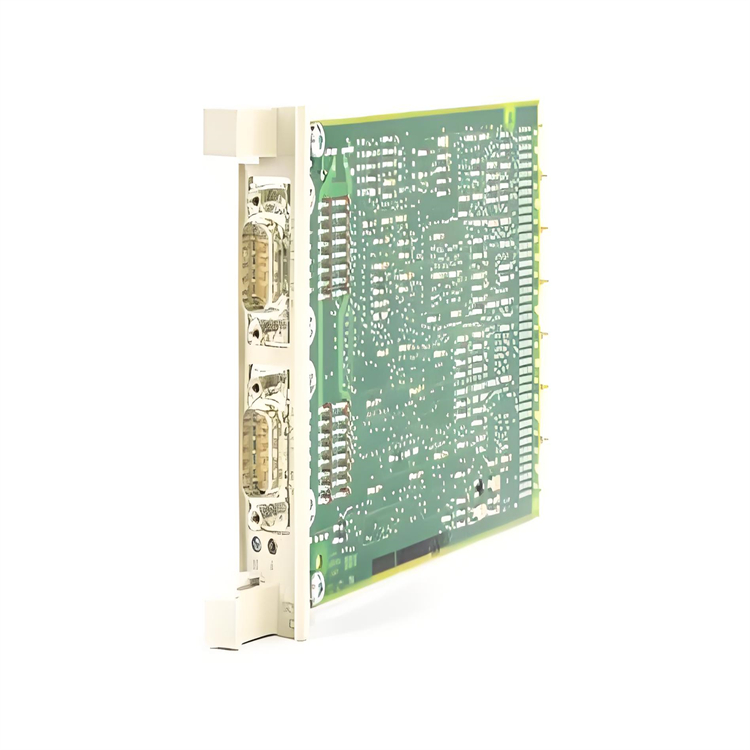

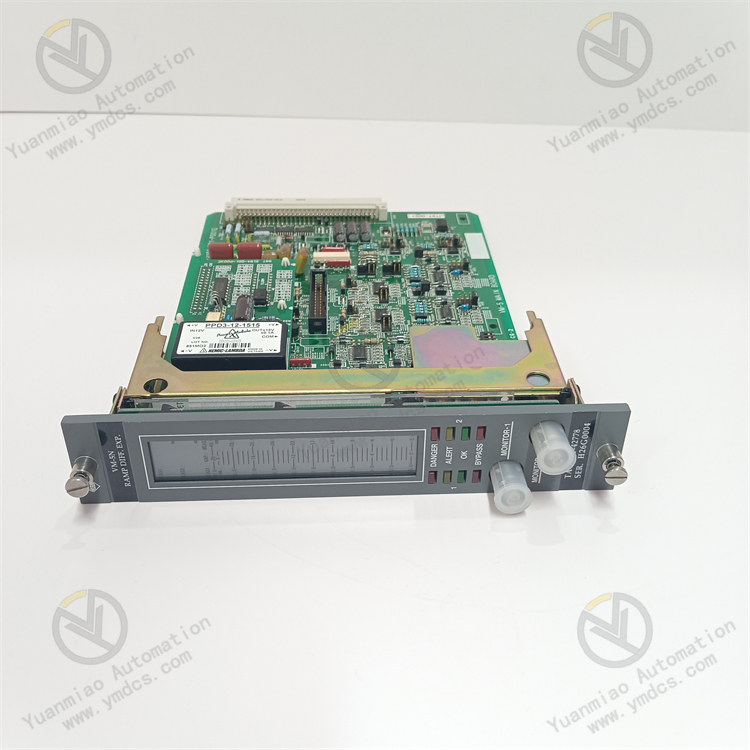

Description

Monitoring and Diagnosis: It has the functions of real-time monitoring and fault diagnosis, which can promptly detect potential problems and provide relevant information, facilitating maintenance personnel to quickly locate and solve faults.

Features

High-precision Control: It can provide accurate control parameters to ensure the precise operation and stability of the system, and is suitable for occasions with strict requirements for precision.

Quick Response: It has the ability of high-speed response, can quickly adjust and adapt to load changes, maintain the stability of the system, and enable the equipment to promptly respond to various changes in working conditions.

Multiple Control Modes: It supports multiple modes such as position control, speed control, and torque control, and can be flexibly selected according to different application requirements, enhancing the applicability of the system.

Industrial-grade Design: It complies with industrial standards, has high reliability, anti-interference ability, and durability, and can operate stably in various harsh industrial environments such as high temperature, high humidity, and strong electromagnetic interference.

Application Areas

Automated Production Lines: It is used for precise motion control and mechanical operation in industrial automated production lines, which helps to improve production efficiency and product quality.

Machining Equipment: It is suitable for numerical control machine tools, robots, and other precision mechanical equipment, and can ensure the stable operation of the equipment and achieve efficient machining.

Testing and Experimental Equipment: It is applied in testing and experimental equipment such as laboratory equipment and scientific research instruments, and can ensure precise motion control and data collection.

Common Faults and Solutions 1. Decline in Motion Control Precision Possible Reasons: Wear of mechanical components, such as the wear of guide rails, lead screws, etc. after long-term use, affecting the motion precision; Sensor failure, such as a decrease in the precision or deviation of the position sensor; The equipment is not firmly installed, causing vibration or displacement during operation. Solutions: For worn mechanical components, replace or repair them in a timely manner. If necessary, recalibrate and adjust the guide rails, lead screws, etc.; Check the sensor, replace it if there is a fault, and recalibrate the sensor; Check the installation condition of the equipment to ensure that the equipment is firmly installed. If necessary, reinstall the equipment and adjust the level. 2. Equipment Fails to Start Possible Reasons: Power supply failure, such as a damaged power cord, a loose power plug, or abnormal power supply; Electrical control system failure, such as a controller failure, a damaged circuit board, or a blown fuse; Loose or damaged connection cables inside the equipment. Solutions: Check the power connection to ensure that the power cord is intact and the plug is firmly connected, and measure whether the power supply is normal, such as voltage, current, etc.; Check the electrical control system, check whether there are fault prompts on the controller, and check whether the components on the circuit board are damaged. If necessary, replace the damaged components or circuit board; Check the connection cables inside the equipment to ensure that all cables are firmly connected, and replace them if they are damaged.

3. Abnormal Noise during Operation Possible Reasons: Loose or worn mechanical components, such as loose or severely worn components like gears and bearings; Insufficient lubrication, lack of sufficient lubrication for mechanical moving components, resulting in increased friction; The equipment is not installed level or the foundation is unstable, generating vibration and noise during operation. Solutions: Check the mechanical components, tighten the loose components, such as gears, bearings, etc., and check for wear. If there is wear, replace them; Lubricate the mechanical moving components, use the appropriate lubricant according to the equipment requirements, and ensure sufficient lubrication; Check the installation condition of the equipment, adjust the level of the equipment, reinforce the equipment foundation, and reduce vibration and noise.

4. Abnormal Sensor Data Possible Reasons: The sensor is interfered with, such as electromagnetic interference, electrostatic interference, etc., affecting the normal operation of the sensor; The installation position of the sensor has changed, resulting in inaccurate measurement data; The sensor itself has a fault, such as aging, damage, etc. Solutions: Check the shielding condition of the sensor to ensure that the sensor cable has good shielding measures to avoid electromagnetic interference; Check the installation position of the sensor, if there is a change, readjust it to the correct position and calibrate it; Replace the faulty sensor, select a sensor that matches the original model for installation and debugging.

5. Software Operation Failure Possible Reasons: The software version is too low, with compatibility problems or software vulnerabilities; The software is attacked by viruses or malicious software, resulting in abnormal system operation; Equipment hardware failures affect the normal operation of the software, such as insufficient memory, damaged hard disk, etc. Solutions: Update the software version in a timely manner to ensure that the software is compatible with the equipment hardware and fix the known vulnerabilities; Perform anti-virus treatment on the equipment, remove viruses and malicious software, and if necessary, reinstall the operating system and software; Check the equipment hardware, such as increasing the memory, replacing the hard disk, etc., to ensure that the hardware meets the requirements for software operation.

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.