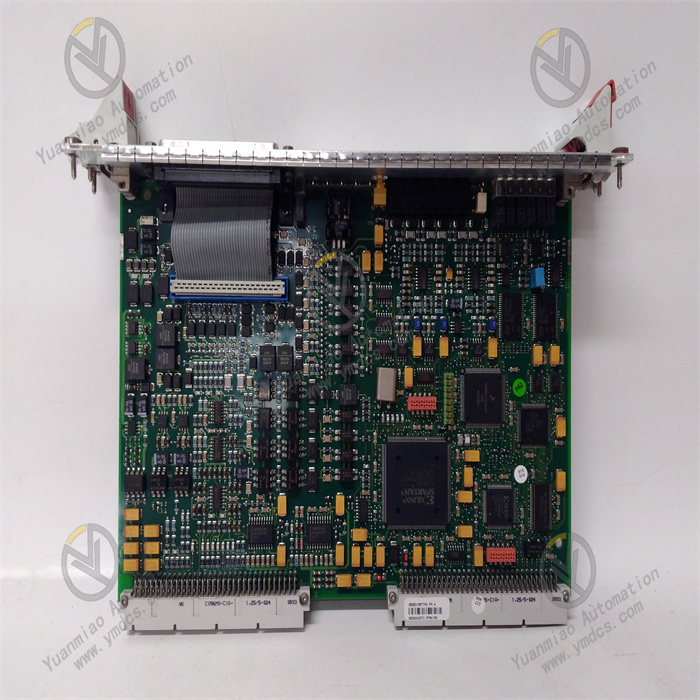

Description

The ABB AI880A 3BSE039293R1 is an analog input module, and its working principle is as follows: 1. Signal Acquisition: This module can be connected to multiple analog sensors, such as thermocouples, resistance temperature detectors (RTDs), or other types of analog transmitters. These sensors convert physical quantities (such as temperature, pressure, flow, etc.) into corresponding analog electrical signals (such as voltage or current signals). The AI880A module acquires these analog electrical signals through its input channels. 2. Signal Conditioning: The acquired analog signals may have differences in amplitude, offset, etc., and may be interfered by noise. The module conditions the input signals, including operations such as amplification and filtering. The amplification operation can amplify small signals to an appropriate amplitude range for subsequent processing; filtering is used to remove high-frequency noise in the signals to improve the quality and stability of the signals. 3. Analog-to-Digital Conversion: The conditioned analog signals need to be converted into digital signals so that controllers (such as PLCs) can process and analyze them. The AI880A module has a built-in analog-to-digital conversion circuit, and usually adopts analog-to-digital conversion technologies such as successive approximation type or Σ-Δ type to convert analog signals into corresponding digital codes. These digital codes represent the amplitude of the analog signals. 4. Data Processing and Transmission: The converted digital signals undergo certain data processing inside the module, such as range conversion, linearization processing, etc., to convert the digital codes into engineering unit data corresponding to the actual physical quantities. Then, the module transmits the processed data to the connected controllers or other devices through the internal bus or communication interface for further monitoring, control, and analysis. 5. Diagnosis and Protection: The AI880A module also has a self-diagnosis function, which can monitor its own working status, such as detecting power supply failures, input signal overlimits, module hardware failures, etc. When abnormal situations are detected, the module will send corresponding alarm signals and take certain protective measures, such as stopping data collection or outputting error codes, to ensure the safe and stable operation of the system.

Functional Features 1. Input Channels and Signal Support: It has 8 current input channels and supports single-ended unipolar input signals of 0 - 20mA and 4 - 20mA, and is suitable for the signal input of various industrial sensors and transmitters. 2. Flexible Configuration: It can be used in single or redundant configurations to meet the requirements for system reliability and stability in different industrial scenarios. In the redundant configuration, it can improve the fault tolerance of the system and ensure the continuity of key measurement tasks. 3. Isolation Characteristics: The 8 channels are divided into 1 group and isolated from the ground, which can effectively prevent external interference signals from entering the system, ensure the accuracy and stability of the measurement signals, and enhance the anti-interference ability of the module in a complex electromagnetic environment. 4. Diagnosis and Protection Functions: It has advanced onboard diagnosis functions, which can monitor the working status of the module in real time and detect faults and give alarms in a timely manner. It also has protection functions such as loop supervision DI function, configurable field power output alarm limits, configurable over/under range of current input, and current-limited transmitter power for each channel, which can effectively protect the module and external devices from abnormal signals and overcurrent and other faults. 5. Communication Protocol: It supports HART pass-through communication, which is convenient for communication and interaction with other devices that support the HART protocol, and can achieve remote monitoring and parameter setting of field devices.

Technical Parameters Physical Parameters: Width is 45 mm, depth is 102 - 111 mm (including connectors), height is 119 mm, weight is 0.15 kg, and it is installed using a DIN rail, which is convenient for installation and layout in an industrial control cabinet. Electrical Parameters: The input impedance is 250Ω (with shunt bar TY801), the module power is generated by 24V DC on the ModuleBus, the rated insulation voltage is 50V, the maximum input voltage (non-destructive) is 11V DC, and the power consumption is low. Performance Parameters: The resolution is 12 bits, the maximum temperature drift is 50ppm/°C, the rise time of the input filter (0 - 90%) is 190ms (hardware filter), the update cycle time is 10 milliseconds, the common mode rejection ratio (50Hz, 60Hz) is greater than 40 decibels, the maximum field cable length is 600 meters, and the overrange is + 12% (0 - 20mA) and +15% (4 - 20mA).

Common Faults and Solutions

1. No signal input or abnormal signal in the channel

Cause Analysis: It may be due to poor connection, open circuit or short circuit of the input signal line; transmitter failure; damage to the module channel; incorrect configuration parameters.

Solutions: Check the input signal line to ensure a firm connection, no open circuit or short circuit, and replace the line if it is damaged; check the working status of the transmitter, and repair or replace it if there is a fault; try to replace the module channel to determine whether the channel is damaged; check the configuration parameters of the module to ensure that they match the actual input signal.

2. Communication Failure

Cause Analysis: Communication line failure; incorrect communication parameter settings; damage to the communication interface of the module; HART device failure.

Solutions: Check the communication line to ensure a normal connection, no looseness or damage; check and verify the communication parameters, such as baud rate, address, etc., to ensure consistency with other devices; check the communication interface of the module, and contact the manufacturer for repair or replacement if it is damaged; check the working status of the HART device and eliminate device failures.

3. Module Overheating

Cause Analysis: Poor ventilation in the installation environment; excessive module load; too high environmental temperature.

Solutions: Improve the installation environment to ensure that there is enough space around the module for ventilation and heat dissipation; check the load situation of the module, reasonably allocate tasks, and avoid long-term full-load operation; if the environmental temperature is too high, take cooling measures, such as installing an air conditioner or a fan.

4. Power Supply Failure

Cause Analysis: Unstable power supply voltage; power supply module failure; open circuit or short circuit of the power supply line.

Solutions: Use a multimeter to measure the power supply voltage to ensure that it is within the allowable working voltage range of the module. If it is unstable, check the power supply or UPS; check the power supply module and replace it if there is a fault; check the power supply line and repair the open circuit or short circuit fault.