Description

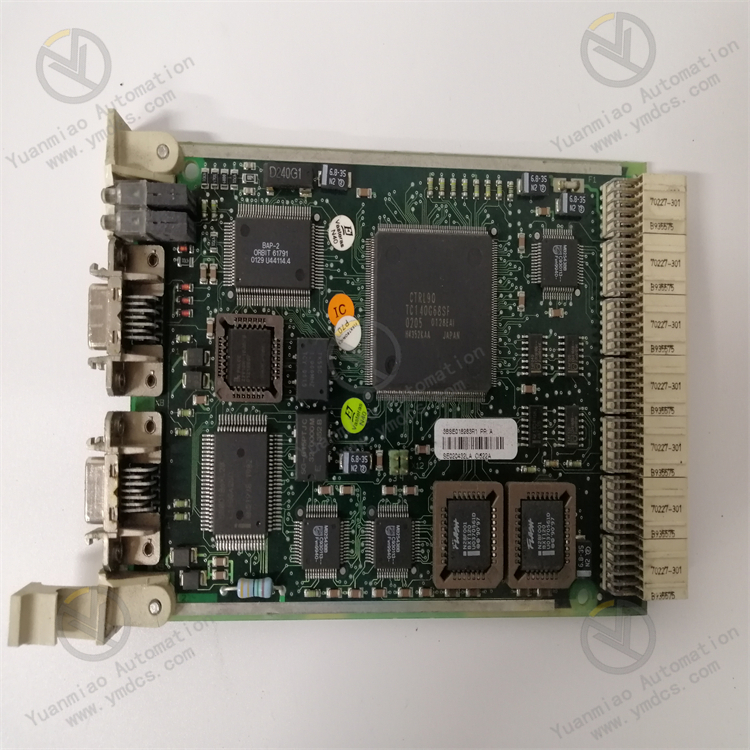

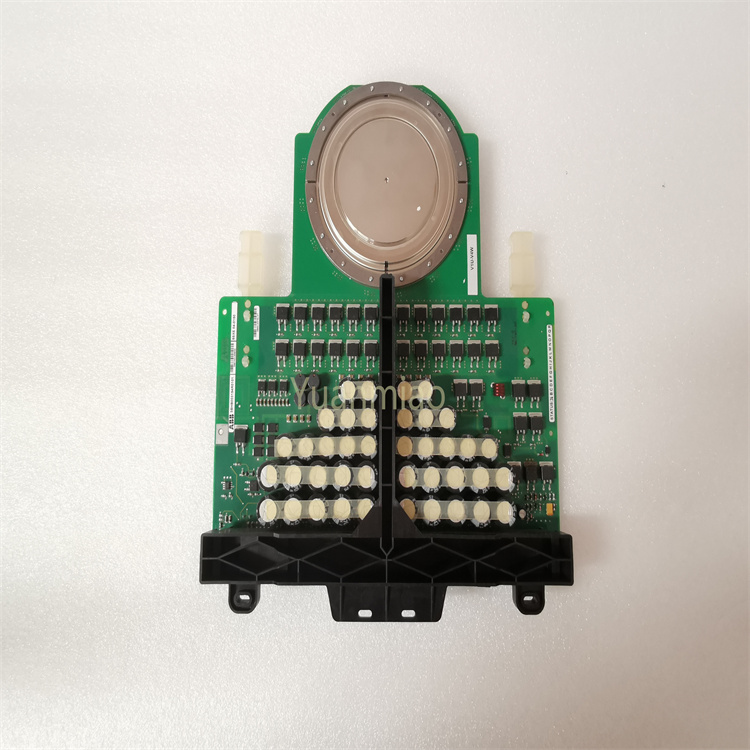

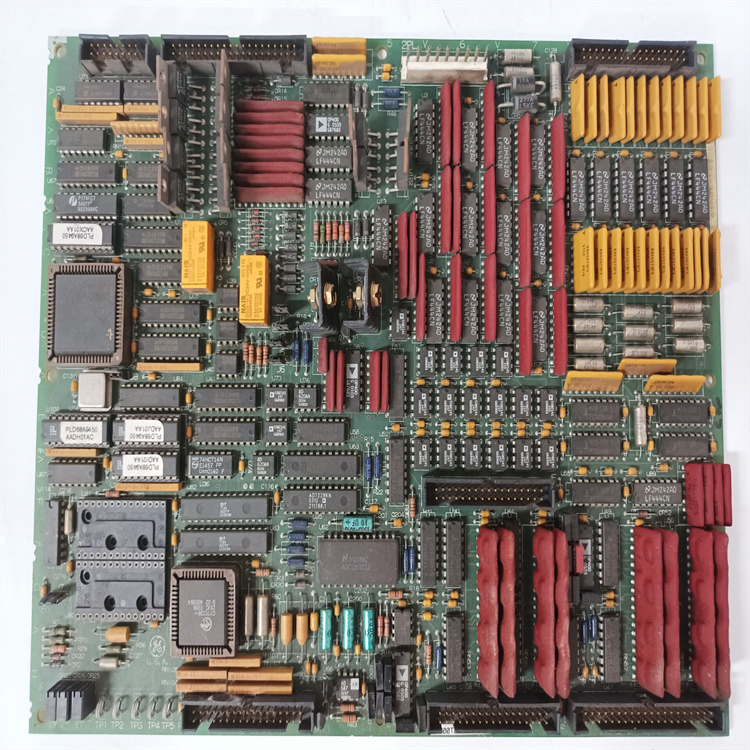

Functional Features Multifunctionality: It can be widely applied to control systems of different types of engines, turbines, and industrial equipment. It supports various types of input and output signals and can achieve multiple control and monitoring functions. High-performance processing capability: By adopting advanced digital signal processing technology, it has powerful computing and processing capabilities. It can efficiently handle a large amount of data and complex control algorithms to achieve precise and stable control. Flexible programming and configuration: It has flexible programming and configuration options, supporting multiple programming languages and development tools, such as C language and Woodward control software. This enables users to easily develop and debug programs and customize according to specific application requirements. Reliability and stability: By using high-quality components and strict quality control, it can operate stably for a long time in harsh working environments to ensure the reliability and safety of the system. Multiple communication interfaces: It supports multiple communication interfaces such as RS485, Ethernet, and CAN bus, and can exchange data and integrate with other devices and systems, being suitable for complex networked control systems. Easy installation and maintenance: It has a compact design and convenient terminal blocks, making installation and maintenance very simple. It also provides self-diagnosis and fault diagnosis functions, which can timely detect and report system faults to improve maintenance efficiency. It also supports hot-swapping.

Technical Parameters Operating voltage: Usually 240V, but it may vary depending on different application scenarios or models. Please refer to the product instruction manual for details. Input and output signal types: It supports various types of input and output signals. It can receive analog signals (such as voltage and current signals) and digital signals (such as pulse signals and switch signals), etc. The output signals also include analog output and digital output to meet the control requirements of different devices. Control accuracy: With its powerful computing and processing capabilities, it can achieve high control accuracy. The specific accuracy indicators may vary according to different control parameters and application scenarios, but generally, it can reach a high level to ensure the precise operation of the system. Response time: Due to the adoption of advanced digital signal processing technology, it has a fast response speed. It can promptly react to changes in input signals and quickly adjust the output to meet the control requirements of the system, usually within milliseconds.

Application Areas 3. Power industry: It can be used in the control systems of generators to achieve precise speed regulation and voltage regulation of generators, ensuring the stable quality of the output electrical energy. It can also be applied to the control of other auxiliary equipment in power stations, such as the operation control of fans and water pumps, to optimize the operation efficiency of the equipment and reduce energy consumption. 2. Petrochemical industry: It plays a role in key equipment such as compressors, pumps, and turbines. By precisely controlling the operating parameters of the equipment, it ensures the stability and safety of the technological process and meets the different working condition requirements in the petrochemical production process. 1. Industrial automation field: It is suitable for the control of various industrial production equipment, such as machine tools, printing machines, and textile machines, etc. It can achieve precise control of parameters such as the speed, position, and torque of the equipment to improve production efficiency and product quality.

Common Faults and Solutions

1. Power supply fault

Phenomenon: The device has no display or cannot start properly.

Cause: Open circuit or short circuit of the power supply line, power supply module failure, abnormal input voltage.

Solution: Check whether the power supply line connection is good. Use a multimeter to detect the continuity of the line and whether the input voltage is within the specified range. If the power supply module is damaged, replace it with a module of the same model.

2. Communication fault

Phenomenon: Communication with other devices or systems is interrupted, and data cannot be transmitted or received, or data transmission errors occur.

Cause: Damaged communication interface, incorrect communication protocol settings, communication line failure, electromagnetic interference.

Solution: Check whether the communication interface has physical damage and reconfirm whether the communication protocol settings are correct. Use tools such as an oscilloscope to detect the signal transmission of the communication line and eliminate line failures. If there is electromagnetic interference, take shielding measures or adjust the installation position of the device.

3. Control anomaly

Phenomenon: There is a large deviation between the actual control effect and the set value, the system operates unstably, or abnormal control actions occur.

Cause: Sensor failure, actuator failure, improper controller parameter settings, software program errors, equipment aging.

Solution: Check the measurement accuracy and working status of the sensor and replace it in time if it is damaged. Check whether the actuator moves flexibly and whether there are phenomena such as jamming or wear, and carry out corresponding maintenance or replacement. Readjust the controller parameters for calibration and optimization. Check whether the software program has errors or loopholes and update or repair it. For aging equipment, carry out maintenance or overall replacement according to the situation.

4. Module overheating

Phenomenon: After the device runs for a period of time, the module temperature is too high, and the overheating protection mechanism may be triggered, resulting in a decline in device performance or shutdown.

Cause: Poor heat dissipation, such as poor ventilation at the installation position, failure of the cooling fan; long-term high-load operation of the equipment; too high environmental temperature.

Solution: Improve the installation environment to ensure that there is enough ventilation space around the equipment. Check whether the cooling fan is operating normally and replace the fan in time if there is a fault. Reasonably arrange the operation tasks of the equipment to avoid long-term high-load operation. If the environmental temperature is too high, take cooling measures, such as installing an air conditioner or strengthening ventilation and heat dissipation.