Description

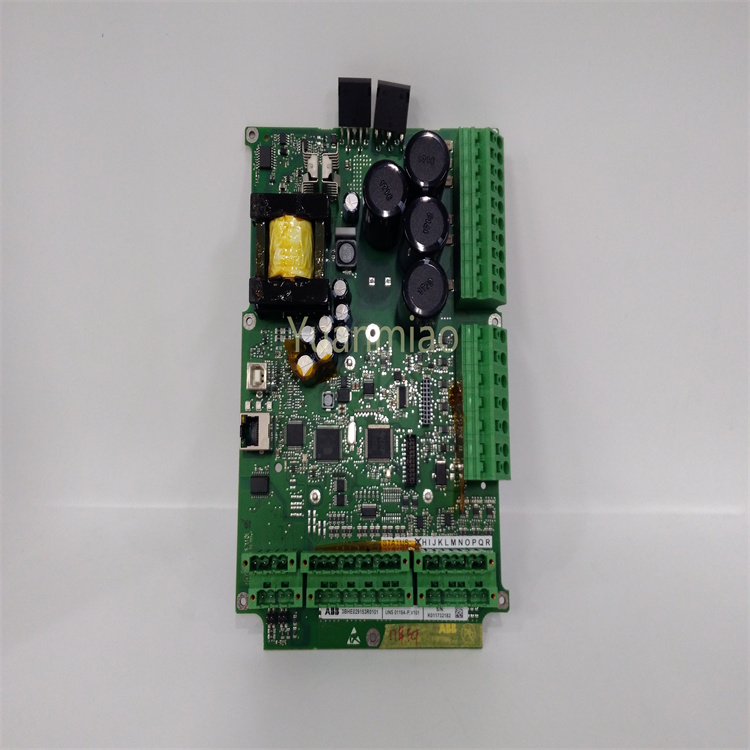

ABB PMGK113ver3.1

The ABB PMGK113ver3.1 3BSE055636R1 is a high-performance industrial control module developed by ABB, designed for complex automation systems. As a key component of ABB's control product portfolio, this module integrates reliable hardware architecture and advanced control algorithms, serving as an interface for signal processing and system coordination in industrial applications such as power generation, manufacturing, and process control.

- Input Voltage: 24V DC (±10% tolerance)

- Power Consumption: ≤12W

- Voltage Protection: Transient overvoltage suppression

- Analog Inputs: 8 channels (0-10V DC / 4-20mA)

- Digital Outputs: 8 channels (24V DC, opto-isolated)

- Resolution: 12-bit (analog), 16-bit (digital)

- RS485 (Modbus RTU)

- Ethernet (Modbus TCP/IP)

- Operating Temperature: -25°C to +70°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5%-95% (non-condensing)

- Protection Level: IP20

- Dimensions: 100mm × 80mm × 50mm

- Weight: Approximately 0.5kg

Supports simultaneous acquisition of analog signals and digital output control, enabling real-time monitoring of parameters like voltage, current, and temperature, and converting field signals into standardized outputs for control systems.

Compatible with industry-standard protocols (Modbus), allowing seamless integration with PLCs, SCADA systems, and HMIs. It facilitates remote configuration and data logging for efficient system management.

Built-in overvoltage, overcurrent, and ESD protection safeguards against transient faults. Opto-isolated channels prevent ground loops and electromagnetic interference, enhancing system reliability.

Enables module replacement without powering down the system, minimizing downtime. The standardized structure supports easy expansion of I/O capacity to meet evolving production needs.

- Ensure the power is off before mounting the module on a DIN rail or control panel.

- Connect 24V DC power supply to the designated terminals, ensuring correct polarity.

- Wire analog/digital signals using shielded cables to minimize interference.

- Use ABB's dedicated software (e.g., AC 800M Control Builder) to set parameters via RS485 or Ethernet.

- Configure I/O mapping, communication protocols, and signal scaling according to application requirements.

- Power on the system and check the status LED: green for normal operation, red for fault.

- Perform signal loop testing to verify analog input accuracy and digital output responsiveness.

- Regularly clean the module to prevent dust accumulation.

- Monitor input voltage stability and check for loose connections in terminals.

- Update firmware periodically via ABB's official platform to ensure optimal performance.

- Refer to the module's front-panel LED fault codes and follow troubleshooting steps in the manual (e.g., E001 for overvoltage).

- For persistent issues, contact ABB technical support and provide the fault log for professional diagnosis.

![]()