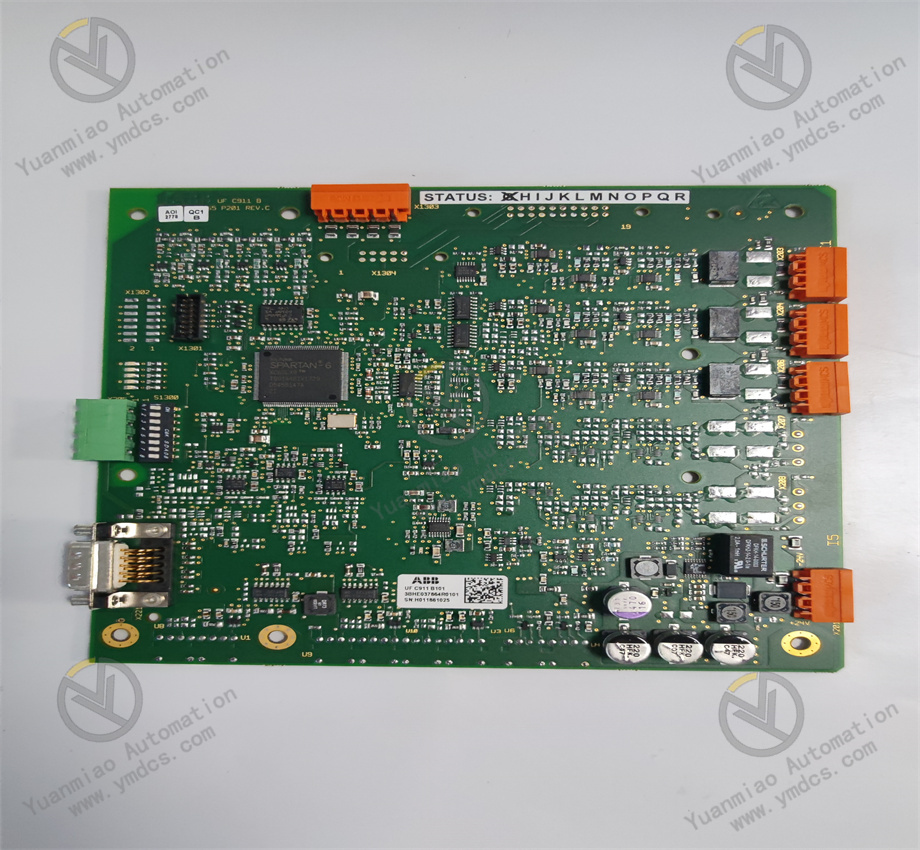

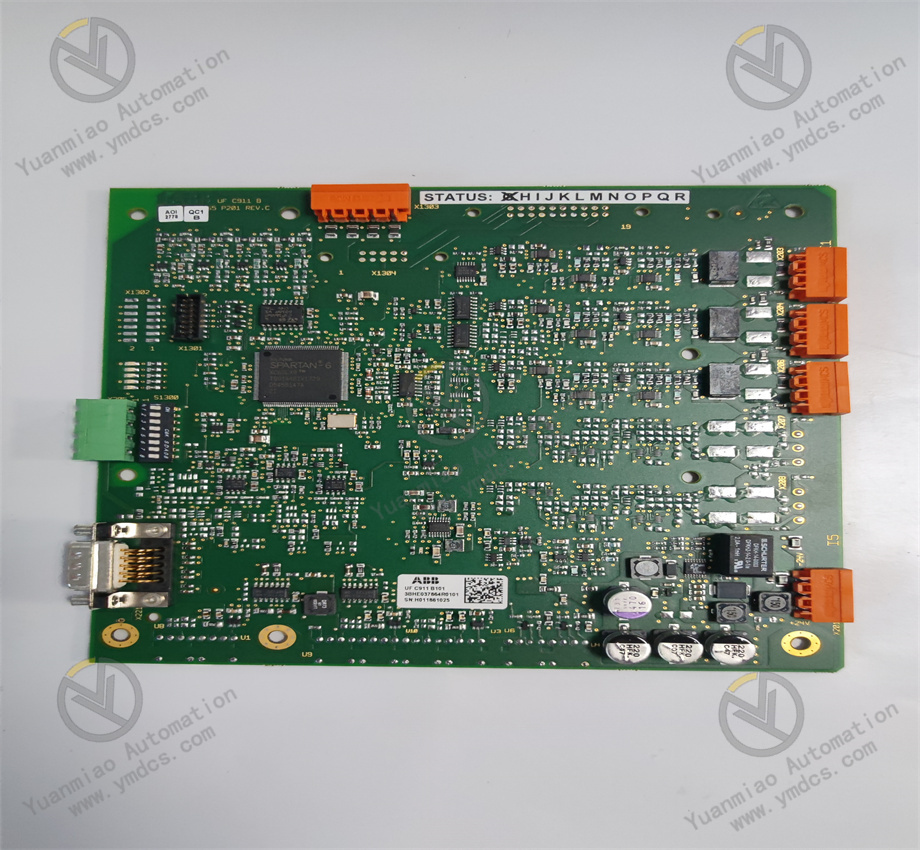

Description

Main Functions Data Processing and Control: It has powerful data processing capabilities and can collect and process signals from various sensors in real-time, such as temperature, pressure, flow rate, etc. It can also precisely control industrial processes according to preset control algorithms and logic to ensure the stability of the production process and the consistency of product quality. Communication Function: It supports multiple communication protocols and can perform data interaction and communication with other devices and systems. For example, the Ethernet communication interface facilitates connection with the host computer, other controllers, or intelligent devices to achieve remote monitoring and data transmission. It may also be equipped with fieldbus interfaces, such as Profibus, Modbus, etc., to facilitate communication with distributed field devices. Redundancy and Reliability Design: To meet the high-reliability requirements of industrial applications, the UFC911B101 may adopt a redundancy design, such as redundant power supply modules, redundant communication links, etc., to ensure that the system can still operate normally when some components fail, reducing downtime and production losses.

Application Areas: It is mainly applied in scenarios with high requirements for control reliability and real-time performance, such as power plants, substations, and large industrial production lines. For example, in a power plant, it can be used to control the operating parameters of the generator set and monitor the equipment status to ensure the safe and stable power generation process. In an industrial production line, it can precisely control the actions of production equipment, coordinate various production links, and improve production efficiency and product quality. Application Scenario Cases: Power System Power Plant Automation Control: In a large thermal power plant, the UFC911B101 can be used to monitor and control the operating parameters of the generator set, such as voltage, frequency, power factor, etc. By collecting sensor data in real-time, conducting precise calculations and analyses, and adjusting the excitation system, speed regulation system, etc. of the generator according to the preset control strategy, it ensures the stable operation of the generator set and meets the power supply requirements of the power grid. For example, when the power grid load changes, the UFC911B101 can respond quickly and automatically adjust the output power of the generator to maintain the stability of the grid voltage and frequency. Substation Integrated Automation: In a substation, the UFC911B101 can serve as the core control module to achieve the monitoring and protection of various electrical equipment in the substation. It can collect signals such as switch status, current, and voltage, conduct fault diagnosis and analysis. When an abnormal situation occurs, it can promptly send out an alarm signal and take corresponding protective measures, such as automatic tripping, to ensure the safe and reliable operation of the substation. At the same time, it can also perform data interaction with the superior dispatching center through the communication interface to achieve remote monitoring and dispatching management.

Industrial Automation Production Line

Automobile Manufacturing Production Line: In the painting production line of an automobile production workshop, the UFC911B101 can be used to control the operation of painting equipment, such as automatic painting robots, ovens, etc. According to the shape and process requirements of the automobile body, it can precisely control the movement trajectory and painting parameters of the painting robot to ensure uniform painting quality. At the same time, it can monitor and control environmental parameters such as the temperature and humidity of the oven in real-time to ensure the drying effect and quality of the paint.

Food and Beverage Production Line: In the beverage filling production line, the UFC911B101 can be used to control the coordinated operation of equipment such as filling machines, capping machines, and labeling machines. By monitoring and controlling the material flow and equipment operation status on the production line in real-time, it achieves precise filling, capping, and labeling of beverages, improving production efficiency and product quality. In addition, it can quickly diagnose and handle production line faults, reducing downtime and ensuring the continuous and stable operation of the production line.

GuiZhou YuanMiao Automation Technology Co., Ltd.

Specialized in industrial automation, we provide original imported DCS system parts, PLC system components, and comprehensive solutions for global clients. With the core values of "Leading Technology, Service Excellence," we leverage extensive industry experience and premium supply chain resources to become your reliable partner for equipment upgrades and maintenance.

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage