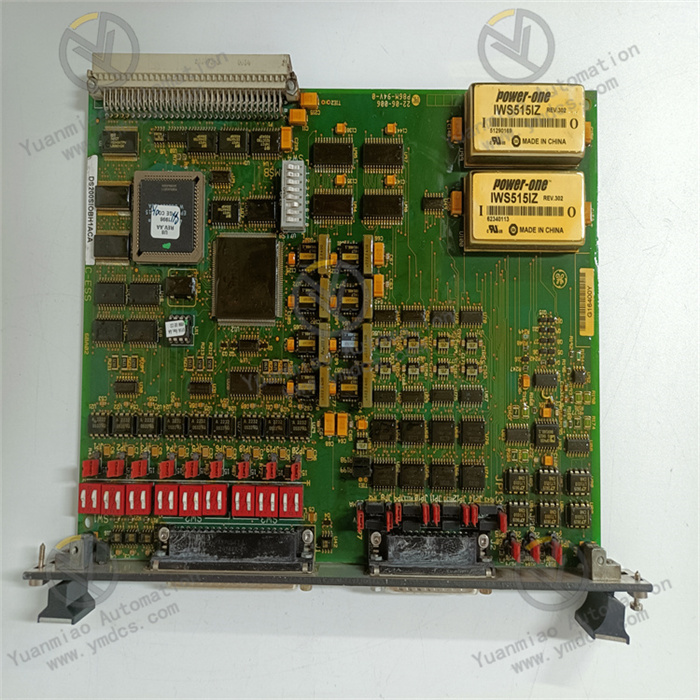

Description

GE IC670ALG310-JA

The GE IC670ALG310-JA is an analog input module for the PACSystems RX3i series, specifically designed for high-precision acquisition of multiple types of analog signals in industrial on-site scenarios. Its core function is to convert continuously changing analog signals (such as temperature, pressure, flow rate, liquid level—e.g., 4-20mA current signals, 0-10V voltage signals) into digital signals, which are then transmitted to the CPU module via the RX3i system backplane bus for arithmetic processing.

With 8 independently configurable channels, wide range adaptability, high-precision acquisition, and strong anti-interference capability, this module is widely used in scenarios requiring strict signal acquisition accuracy, such as petrochemical process control, metallurgical industrial furnace temperature monitoring, power system parameter acquisition, and pharmaceutical industry process monitoring. It is a key front-end component for building high-precision data acquisition systems based on PACSystems RX3i.

- Features 8 independent analog input channels, supporting single-ended or differential input modes (each channel can be configured independently).

- Resolution: 16-bit; full-scale accuracy: ±0.05% (at 25°C); temperature drift: ≤50ppm/°C.

- Sampling rate: Adjustable from 10Hz to 1000Hz; maximum sampling rate per channel: 1000Hz; total rate for 8-channel parallel sampling: 8000Hz, enabling capture of fast-changing dynamic signals.

- Supports multiple types of input signals, including 4-20mA DC current signals, 0-5V/0-10V DC voltage signals, thermocouple signals (Types J/K/T/E/R/S/B), and RTD (Resistance Temperature Detector) signals (Pt100/Pt1000/Cu100).

- Current input impedance: ≤250Ω; voltage input impedance: ≥10MΩ.

- Thermocouple cold-junction compensation accuracy: ±0.5°C; RTD measurement accuracy: ±0.1°C, adapting to the signal output requirements of different types of sensors.

- Compatible with the backplane bus specifications of the PACSystems RX3i series; bus transmission rate: 100Mbps; data transmission delay: ≤10μs.

- Supports module-level hot swapping (requires matching with the RX3i system hot-swap management module), with no impact on the normal operation of other modules during insertion/extraction.

- Equipped with module self-test and fault reporting functions, which feed back acquisition status and fault information to the CPU module in real time via the backplane bus.

- Operating temperature: 0°C ~ 60°C; storage temperature: -40°C ~ 85°C.

- Relative humidity: 5% ~ 95% (non-condensing).

- Vibration resistance rating: IEC 60068-2-6 (10Hz ~ 500Hz, acceleration: 5g).

- Shock resistance rating: IEC 60068-2-27 (peak acceleration: 15g, duration: 11ms).

- Dimensions: 100mm × 160mm × 80mm (compliant with the standard size of RX3i series modules); supports rail-mounted or rack-mounted installation, and is compatible with DIN rail fixing.

The IC670ALG310-JA is designed around the core concepts of "high-precision acquisition, multi-signal adaptation, and high-reliability operation." Its functional features fully meet the strict requirements of high-precision industrial analog signal acquisition, with key advantages as follows:

- The 8 channels can be independently configured into different input types (current, voltage, thermocouple, RTD). For example, 3 channels for 4-20mA signals from pressure sensors, 3 channels for thermocouple signals from furnace temperature monitoring, and 2 channels for RTD signals from ambient temperature monitoring—enabling simultaneous multi-parameter acquisition without module replacement.

- Built-in sensor signal conditioning circuit, allowing direct connection of 2-wire/3-wire sensors without additional signal conditioning modules, reducing system integration costs.

- 16-bit resolution combined with ±0.05% full-scale accuracy enables precise capture of weak signal changes (e.g., minimum distinguishable current of approximately 0.31μA in the 4-20mA range).

- A maximum sampling rate of 1000Hz per channel allows fast response to dynamic signals (e.g., sudden pressure changes in chemical reactors, transient currents in power systems).

- Thermocouples adopt a dual compensation mechanism (hardware + software) for cold-junction compensation; RTDs use 3-wire wiring to eliminate the impact of lead resistance, ensuring stable acquisition accuracy in different environments.

- The 100Mbps high-speed backplane bus enables fast upload of acquired data; when combined with the CPU module, it achieves millisecond-level control response.

- Hot-swap functionality allows module replacement without system shutdown, making it suitable for continuous production scenarios (e.g., petrochemicals, power industry), avoiding production interruptions caused by module maintenance and improving system availability.

- Adopts a triple anti-interference design: "differential input + photoelectric isolation + electromagnetic shielding." Isolation voltage: ≥250V AC; Common Mode Rejection Ratio (CMRR): ≥120dB@50Hz, effectively suppressing electromagnetic interference from on-site equipment such as inverters and motors.

- On-board LED status indicators (power, channel fault, bus communication) are grouped by channel. It supports remote reading of channel acquisition data, calibration parameters, and fault logs via RX3i system software, enabling remote diagnosis and maintenance.

As the "front-end signal acquisition terminal" of the PACSystems RX3i system, the IC670ALG310-JA essentially implements a closed-loop workflow of "signal access → conditioning and conversion → data transmission → status feedback," and collaborates with the CPU module to complete high-precision data acquisition and control. The specific steps are as follows:

- The CPU module sends channel configuration commands to the IC670ALG310-JA via the backplane bus, including input type (e.g., Type J thermocouple), range (e.g., 0-10V), sampling rate (e.g., 100Hz), and filtering parameters (e.g., low-pass filter cutoff frequency) for each channel.

- After receiving the commands, the module initializes its internal signal conditioning circuit, ADC (Analog-to-Digital Converter), cold-junction compensation module, and bus interface to complete preparations for acquisition.

- After the analog signal output by the sensor is connected to the corresponding channel, it first passes through a differential input circuit to suppress common-mode interference.

- Subsequent conditioning is tailored to the channel’s configured type: Current signals are converted to voltage signals via precision resistors; thermocouple signals undergo cold-junction compensation to offset the impact of ambient temperature; RTD signals use constant current source excitation and 3-wire balancing circuits to eliminate lead errors.

- The conditioned analog signal is sent to the 16-bit ADC for conversion to a digital signal, with a conversion error of ≤±1LSB.

- The converted digital signal is processed by the module’s internal MCU (Microcontroller Unit), including noise filtering, linearization calibration (for the nonlinear characteristics of thermocouples), and unit conversion (e.g., converting current values to pressure values).

- The processed data is stored in the module’s buffer. When the buffer reaches a set threshold or the sampling cycle ends, the data is quickly uploaded to the CPU module via the 100Mbps backplane bus.

- Meanwhile, the MCU monitors the channel acquisition status in real time and feeds back status information to the CPU synchronously.

- Built-in channel fault detection circuit monitors in real time whether the input signal exceeds limits (e.g., current >25mA, voltage >12V) or if the sensor is open-circuited/short-circuited.

- If a fault is detected, the fault code is immediately written to the status register, the corresponding channel’s fault indicator is lit, and fault information is reported to the CPU module via the backplane bus.

- Equipped with over-voltage protection (input voltage ≤30V) and over-current protection to prevent module damage caused by sensor faults.

Based on operational experience in high-precision acquisition scenarios, common faults of the IC670ALG310-JA mainly focus on signal acquisition, channel calibration, and bus communication. The following are typical faults and practical troubleshooting methods:

- Possible Causes: Incorrect channel configuration (e.g., input type mismatch with the sensor), wrong sensor wiring (e.g., 3-wire RTD wired as 2-wire), uncalibrated channel, faulty sensor.

- Troubleshooting:

- Verify channel configuration parameters to ensure the input type and range match the sensor output (e.g., Type J thermocouple incorrectly configured as Type K).

- Check sensor wiring: Ensure the three leads of the RTD are connected to the corresponding terminals; distinguish between the positive and negative poles of the thermocouple.

- Calibrate the channel using RX3i system software: Input a known signal with a standard signal source and adjust the calibration coefficient.

- Test with a spare sensor: If the data returns to normal, the original sensor is faulty.

- Possible Causes: Loose/broken sensor wiring, faulty sensor power supply (no power for 2-wire sensors), faulty channel circuit.

- Troubleshooting:

- Power off, re-tighten the sensor wiring terminals, and measure the signal at the wiring end with a multimeter (4-20mA for current signals, 0-10V for voltage signals).

- For 2-wire 4-20mA sensors, check if the module provides 24V DC power and ensure stable power supply.

- Swap the sensor wiring between the faulty channel and a normal channel: If the fault follows the signal, it is an external issue; otherwise, the module channel is faulty and requires repair.

- Possible Causes: Poor sensor grounding, excessive noise amplification due to high acquisition rates, improper filtering parameter configuration, nearby strong interference sources.

- Troubleshooting:

- Check the grounding of the sensor and module: Ensure single-point grounding with a grounding resistance of ≤4Ω.

- Reduce the sampling rate (e.g., from 1000Hz to 100Hz) to reduce high-frequency noise acquisition.

- Reconfigure channel filtering parameters to increase the attenuation coefficient of the low-pass filter cutoff frequency.

- Keep the module away from high-interference equipment (e.g., inverters, high-voltage cables), or cover sensor cables with metal shielding tubes and ground them.

- Possible Causes: Improper module installation (poor backplane bus contact), module address conflict, faulty backplane bus, faulty module power supply.

- Troubleshooting:

- Power off, reinsert the module, and ensure tight contact between the module and the backplane bus.

- Check the module address (via DIP switches or software configuration) to ensure no conflicts with other modules in the system.

- Test the module by installing it in another backplane slot: If communication still fails, the backplane bus is faulty.

- Measure the module power supply voltage with a multimeter (standard: DC 24V) to ensure stability; if abnormal, check the power circuit.

![]()