Description

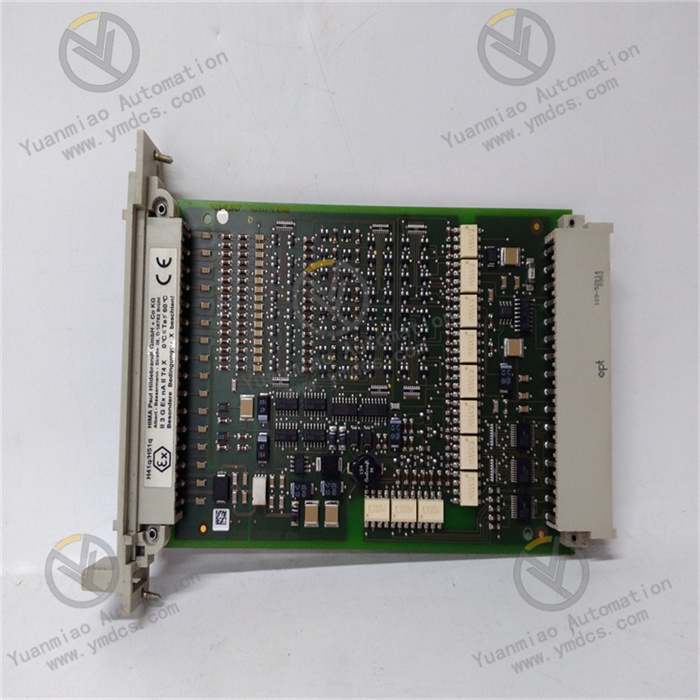

Technical Specifications Number of Channels: It has 8 differential input channels, which can condition and collect multiple signals simultaneously. Input Range: The input range is relatively flexible and can be set to various ranges such as ±200mV, ±500mV, ±1V, ±2V, ±5V, ±10V, etc., to adapt to input signals of different amplitudes. Gain Setting: It provides a variety of gain options, such as 1, 2, 5, 10, 20, 50, 100, 200, etc. Users can adjust it according to the actual signal size and collection requirements. Bandwidth: The bandwidth is usually 10kHz, which can meet the collection requirements of most medium and low-frequency signals. Sampling Rate: The maximum sampling rate can reach up to 250kS/s, enabling effective collection of rapidly changing signals. Isolation Characteristics: There is an electrical isolation function between channels, and the isolation voltage is generally 500Vrms, which can effectively reduce the interference between channels and improve the quality of the collected signals.

Features and Advantages High-precision Signal Conditioning: It can perform processing such as amplification, filtering, and isolation on the input signals, effectively improving the quality and precision of the signals, and providing a reliable basis for subsequent data collection and analysis. Flexible Configuration: The input range and gain can be flexibly set. Users can optimize the configuration according to different application scenarios and signal characteristics, enhancing the versatility and adaptability of the module. Channel Isolation: The electrical isolation design between channels can avoid mutual interference between signals, and it is especially suitable for occasions where multi-channel signals are collected simultaneously and high requirements are placed on the independence of the signals. Good Integration with the NI System: As a part of the NI product line, it can be seamlessly integrated with NI data acquisition cards, software (such as LabVIEW), etc., making it convenient for users to build a complete data collection and testing system. High Reliability: Adopting high-quality electronic components and reliable circuit design, and after strict testing and verification, it can operate stably in complex industrial environments. Application Areas Industrial Automation: In industrial production lines, it is used to collect the signals of various sensors (such as temperature sensors, pressure sensors, strain gauges, etc.) to monitor and control the production process. Testing and Measurement: In the fields of performance testing of electronic devices and product quality inspection, it conditions and collects signals to provide accurate data for testing and analysis. Scientific Research Experiments: In scientific research experiments in physics, chemistry, biology, etc., it collects and processes experimental data to help researchers obtain accurate experimental results. Aerospace: In the testing and monitoring systems in the aerospace field, it collects and conditions various flight parameters and equipment status signals.

Common Faults and Solutions

Inaccurate Signal Conditioning

Possible Causes: Incorrect gain setting, improper selection of the input range, internal circuit failure of the module, etc.

Solutions: Check the settings of the gain and input range to ensure they match the actual signal; Use a standard signal source to calibrate the module. If there are still problems after calibration, it may be an internal circuit failure of the module, and you need to contact NI technical support for maintenance.

Interference between Channels

Possible Causes: Degradation of isolation performance, poor grounding, external electromagnetic interference, etc.

Solutions: Check the grounding of the module to ensure good grounding; Use shielded cables to connect the input signals to reduce external electromagnetic interference; If it is suspected that the isolation performance has degraded, a professional instrument can be used to measure the isolation voltage, and the module may need to be replaced if necessary.

Communication Fault

Possible Causes: Loose connection cables with the data acquisition card or computer, incorrect setting of the communication protocol, damage to the interface, etc.

Solutions: Check whether the connection cables are firm and plug and unplug the cables again; Confirm whether the communication protocol settings are correct, such as baud rate, data bits, stop bits, etc.; If the interface is damaged, the corresponding interface components need to be replaced or professional maintenance personnel need to be contacted for handling.

Abnormal Sampling Rate

Possible Causes: Incorrect software settings, too low firmware version of the module, hardware failure, etc.

Solutions: Check the sampling rate settings in the data acquisition software to ensure they are correct; Update the firmware of the module to the latest version; If the problem still exists, it may be a hardware failure, and further hardware detection and maintenance are required.