Description

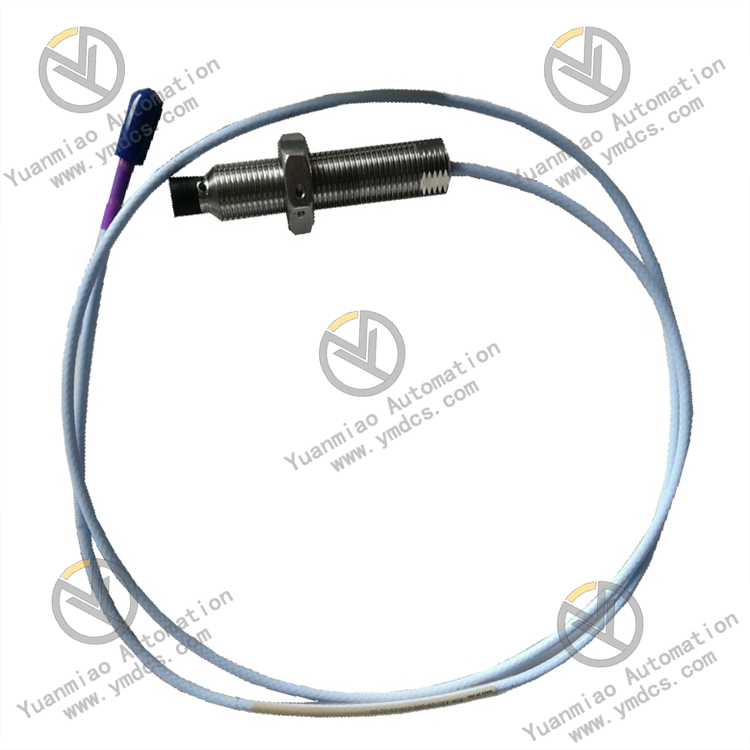

Part Number: 330105-02-12-05-02-05

Manufacturer: Bently Nevada

Product Type: 3300 XL 8 mm Reverse Mount Probes

Storage Temperature : -51 °C to +177 °C (-60 °F to +351 °F)

Total length option : 10 = 1.0 metre (3.3 feet)

Availability: In Stock

Country of Origin: United States(USA)

Functions and Purposes:

Displacement Measurement: It is mainly used for precisely measuring the radial and axial displacements of the shafts of rotating machinery (such as steam turbines, compressors, generators, etc.). By detecting the change in the distance between the shaft and the sensor, it can promptly detect the position deviation of the shaft, providing key data for the evaluation of the equipment's operating status. This enables the adoption of preventive measures in advance to avoid equipment damage caused by excessive shaft displacement.

Vibration Monitoring: It can assist in monitoring the vibration of the shaft and measure parameters such as the vibration amplitude and frequency of the shaft. Abnormal shaft vibration during the operation of the equipment is often an early sign of equipment failure. This sensor helps to detect potential equipment failures in a timely manner, such as imbalance, misalignment, bearing damage, and other issues.

Key Phase Measurement: In the monitoring system of rotating machinery, it is used to determine the rotational position of the shaft, providing a phase reference for other monitoring parameters (such as vibration, displacement, etc.). Through key phase measurement, the rotational state of the shaft can be accurately determined, and various phenomena during the operation of the equipment can be analyzed.

Features: High Precision: It has high measurement precision and resolution, capable of accurately capturing the minute displacements and vibration changes of the shaft, providing reliable data for the precise monitoring of the equipment. High Reliability: Adopting mature eddy current technology, the sensor has a robust structure and can operate stably in harsh industrial environments, such as high temperature, high humidity, strong electromagnetic interference, and other conditions. Non-contact Measurement: The eddy current sensor does not directly contact the measured object, avoiding wear and measurement errors caused by contact. At the same time, it will not interfere with the operation of the measured object, extending the service life of both the sensor and the measured equipment. Good Linearity: Within a certain measurement range, there is a good linear relationship between the sensor's output signal and the measured displacement, facilitating the processing and analysis of the signal. Technical Specifications (Speculation on the Meanings Corresponding to Each Part of the Code): -02: It may indicate parameters related to the type or specification of the probe. Different numbers correspond to different probe designs, such as the diameter and sensitivity of the probe. -12: It may be related to the length of the probe, usually in millimeters (mm). The specific length needs to refer to the product manual. -05: It may represent the length of the cable, also in millimeters (mm), indicating the overall length specification after the sensor probe is connected to the extension cable. -02: It may be related to the type or parameters of the preamplifier. The preamplifier is an important part of the eddy current sensor system, responsible for amplifying and processing the weak signals detected by the probe. -05: It may be some other configuration or option parameters, such as specific identifiers related to the operating temperature range, protection level, etc.

Application Areas:

Power Industry: It is widely used in the operation monitoring of key equipment such as steam turbines and generators in thermal power plants, nuclear power plants, etc., ensuring the safety and stability of power production.

Petrochemical Industry: It is used to monitor the operating status of rotating mechanical equipment such as compressors and pumps in the petrochemical production process, promptly detect equipment failures, and avoid production losses caused by equipment shutdowns.

Metallurgical Industry: It is used in equipment such as rolling mills and fans in steel plants to monitor the shaft displacement and vibration of the equipment, ensuring the normal operation of the equipment and production efficiency.

Other Industrial Fields: In industries such as papermaking, cement, aerospace, etc., as long as it involves the operation monitoring of rotating mechanical equipment, this type of eddy current sensor can be used.

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage

Bently Nevada Related Products

| 149986-02 | 133300-01 |

| 149986-01 | 132419-01 |

| 149787-01 | 130733-01 |

| 149369-01 | 130539-30 |

| 147663-01 | 130539-07 |

| 147025-01 | 129105-01 |

| 146031-01 | 128240-01 |

| 143729-01 | 126648-01 |

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.