Description

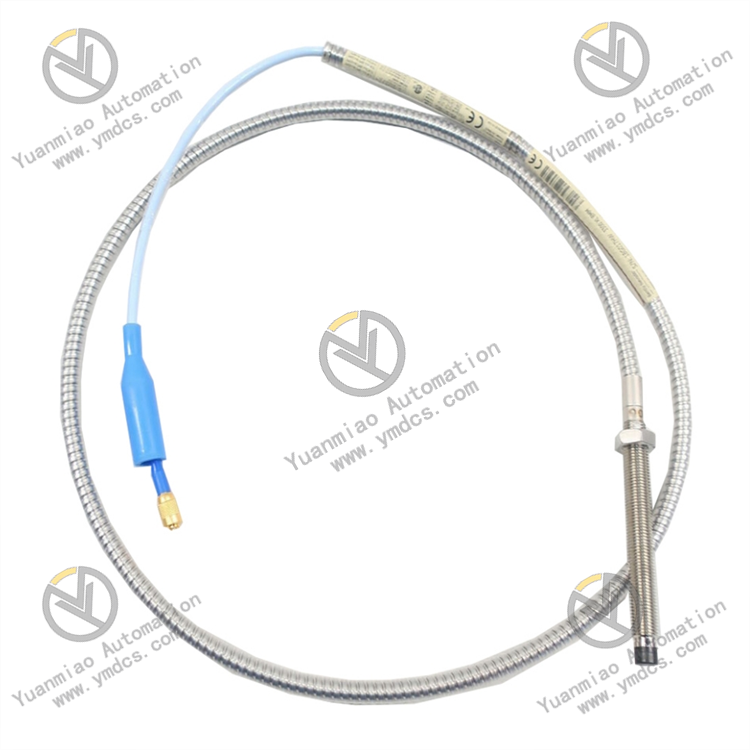

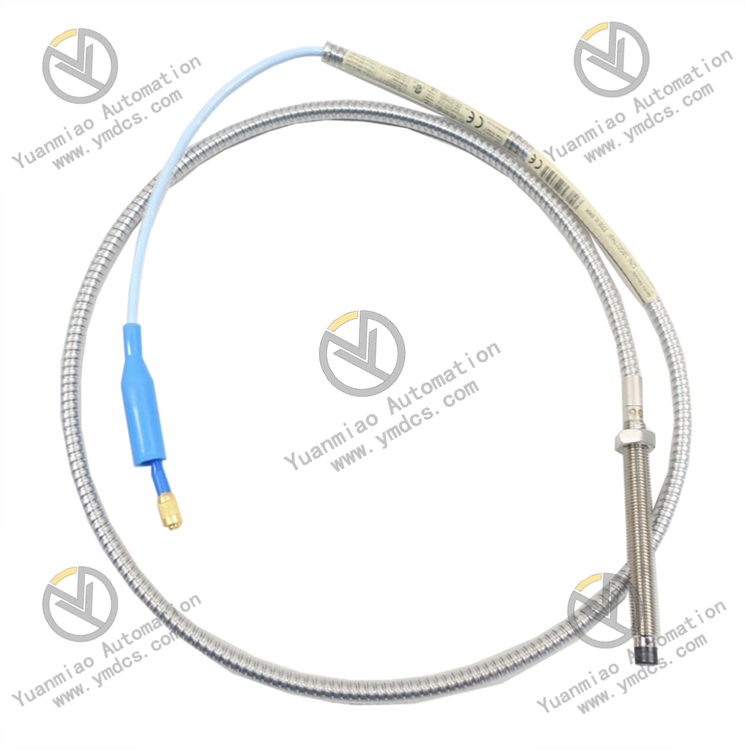

Bently Nevada 330103-00-09-15-05-00 is a proximity probe produced by Bently Nevada. A proximity probe is a sensor used to measure the distance between an object and the probe, and it is commonly used in the monitoring and protection systems of industrial equipment.

Functional Features:

High-precision Measurement: It can accurately measure parameters such as the distance between an object and the probe, shaft displacement, and vibration. The measurement accuracy can reach a high level. For example, the accuracy of measuring shaft displacement can reach ±0.01mm, providing accurate data support for the evaluation of the equipment's operating status, ensuring precise monitoring of the equipment's operating status, and promptly detecting potential problems of the equipment.

Reliable Stability: It adopts high-quality materials and advanced manufacturing processes, and has strong anti-interference ability. It can operate stably in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.). For example, in an environment with strong electromagnetic interference, it can still maintain stable signal output, reducing measurement errors and equipment failures caused by interference.

Wide Measuring Range: It has a wide measuring range and can meet the measurement requirements under different working conditions. For example, the measuring distance range can reach a certain value, adapting to the installation and operation requirements of different equipment. Whether it is large-scale mechanical equipment or small devices, it can accurately measure relevant parameters.

Multiple Output Modes: It supports multiple types of output signals, such as analog output (such as 4 - 20mA) and digital output, etc., making it convenient to connect with other devices (such as data acquisition systems, PLCs, host computers, etc.) and transmit data. The measurement data can be transmitted to the monitoring system in real time to achieve remote monitoring and control of the equipment.

Convenient Installation: It is designed for easy installation and debugging, and can adopt various installation methods, such as threaded installation, flange installation, etc., adapting to the installation requirements of different equipment. At the same time, the probe has a compact structure and occupies a small space, and can be installed in a limited space.

Long Service Life and Maintenance-free: It has a long service life, reducing the replacement frequency and maintenance cost. And under normal operation conditions, frequent maintenance operations are not required, improving the reliability and operation efficiency of the equipment.

Strong Compatibility: It can cooperate well with other equipment of Bently Nevada (such as preamplifiers, monitoring systems, etc.) to achieve comprehensive monitoring and protection of the equipment. For example, in cooperation with the preamplifier, it can process and transmit signals to ensure the accuracy and stability of the signals.

Fault Diagnosis Function: It has a built-in fault diagnosis algorithm, which can monitor the operating status of the probe in real time, promptly detect the faults of the probe, and send out alarm signals. For example, when the probe fails, the fault information can be displayed through the monitoring system, facilitating maintenance personnel to quickly locate and solve the problem.

Technical Parameters: Measuring Range: The linear range is 2mm. Sensitivity: 7.87V/mm (200mV/mil)±5%. Frequency Response: 0-10kHz. Power Supply: -17.5Vdc to -26Vdc, and the current is 12mA. Preamplifier Temperature Range: The operating temperature is from -35°C to +85°C. Preamplifier Weight: 246g. This sensor system is usually used for the vibration monitoring of large and medium-sized rotating machinery such as steam turbines, hydro turbines, fans, and compressors. Faults and Solutions Abnormal Signal: Fault Description: The output signal is unstable, distorted, or there is no signal output. Possible Reasons: Loose probe installation, poor cable connection, preamplifier failure, probe damage, electromagnetic interference, etc. Solutions: Check whether the probe installation is firm and tighten the installation bolts with a torque wrench; check whether the cable joints are loose or damaged, and reconnect or replace the cable if there are problems; measure the resistance of the probe with a multimeter, and replace the probe if it deviates from the standard range; use a twisted-pair shielded cable, and ground the shielding layer at one end to suppress electromagnetic interference. Power Supply Fault: Fault Description: The probe cannot work properly, and there may be phenomena such as the power indicator not lighting up. Possible Reasons: Failure of the 24VDC power module, short circuit or open circuit of the line, damage to the internal circuit of the sensor. Solutions: Measure whether the voltage at the power output terminal is stable at 24±0.5V, and replace the power module if it is abnormal; check whether the insulation layer of the sensor cable is damaged to avoid the line being short-circuited to the ground; check whether there is an open circuit in the line, and repair or replace the damaged line. Large Measurement Error: Fault Description: There is a large deviation between the measured value and the actual value. Possible Reasons: Incorrect probe installation position, abnormal calibration parameters, excessive equipment vibration, etc. Solutions: Check whether the probe installation position meets the requirements and readjust the installation position; execute the "Auto - Zero" function through the Bently system software to eliminate the zero error, input a standard signal with a standard vibration table to verify whether the output error is within the allowable range, and adjust the built-in gain potentiometer of the sensor if the deviation is large; check the vibration situation of the equipment, overhaul and maintain the equipment to reduce vibration interference.

Main Products:

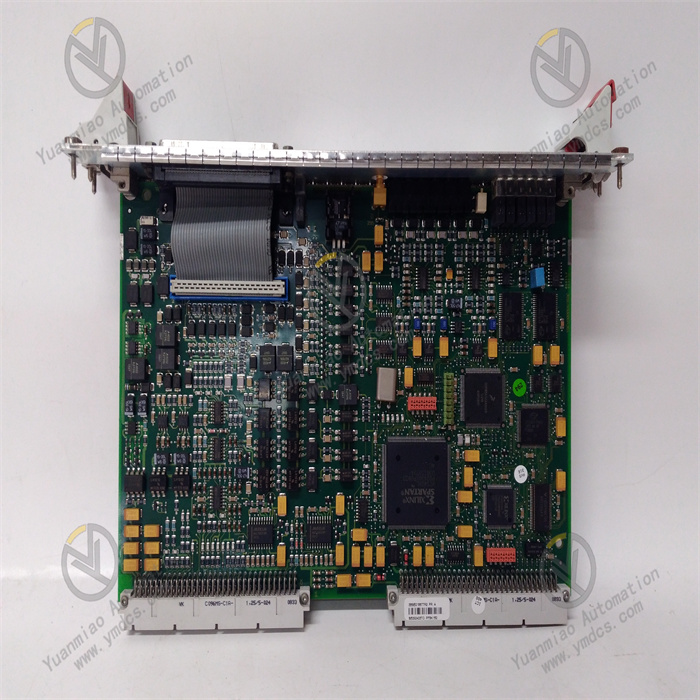

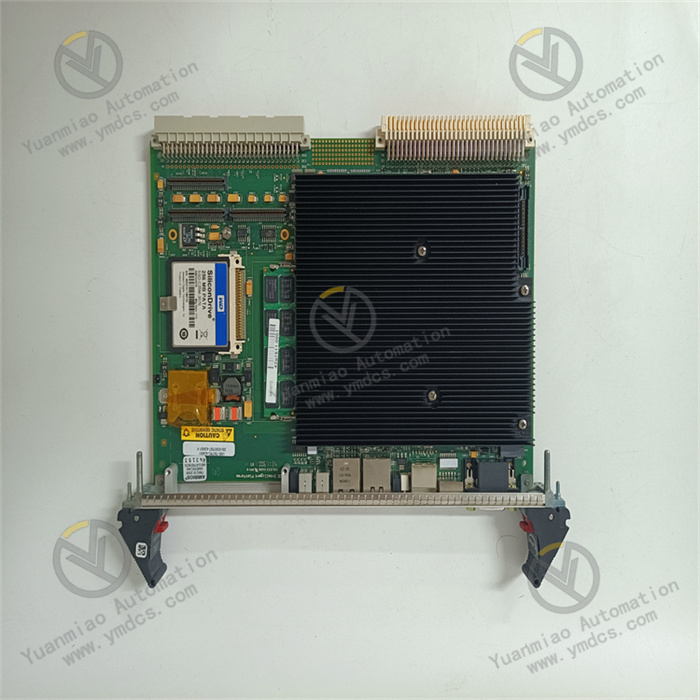

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage