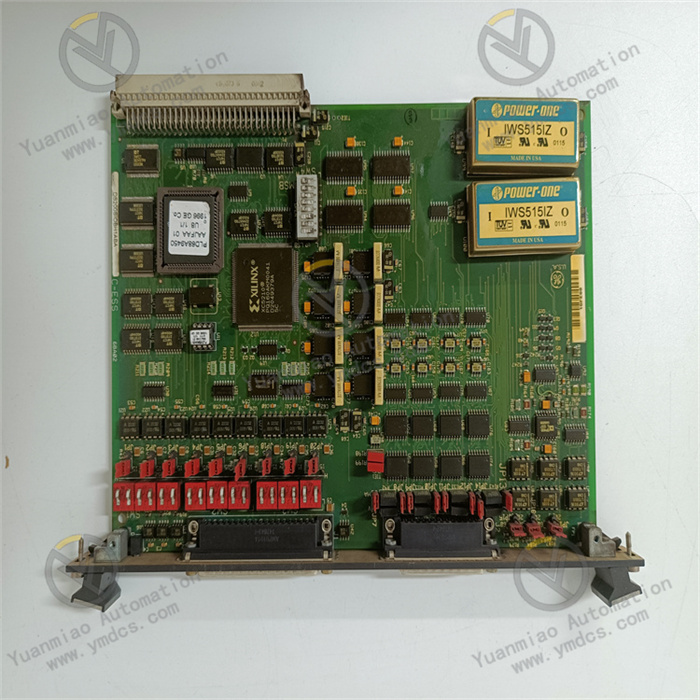

Description

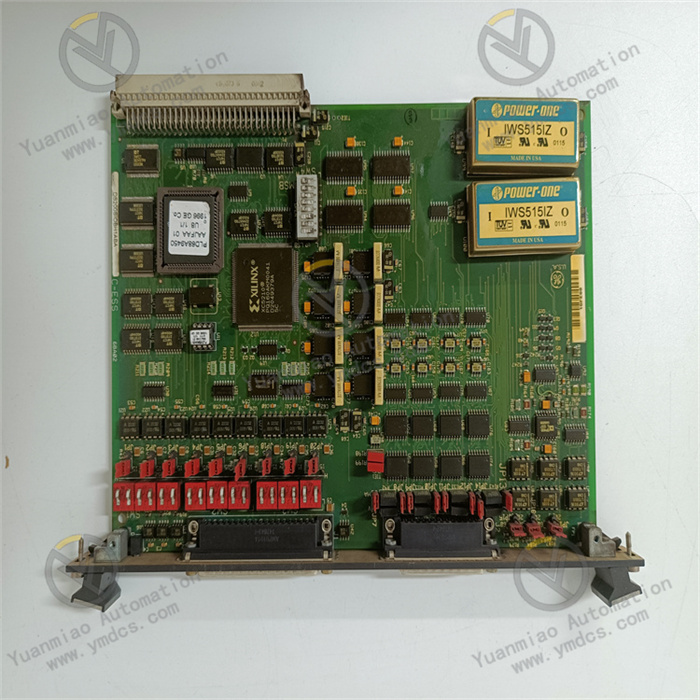

GE DS200GDPAG1ALF

The GE DS200GDPAG1ALF is a core digital input module for the Mark VIe series gas turbine/steam turbine control system. Its core positioning is a "digital signal acquisition unit for large rotating machinery control systems", focusing on solving the problems of accurate acquisition and real-time transmission of various digital status signals during the operation of large power equipment such as gas turbines, steam turbines, and generators. This module is highly compatible with the GE Mark VIe control system, adopting a high-density channel design, industrial-grade enhanced circuits, and a redundant fault-tolerant architecture. It undertakes the key task of converting on-site digital signals (dry contacts/wet contacts) from limit switches, pressure switches, temperature switches, solenoid valve feedback, etc., into digital signals recognizable by the control system, and transmitting them to the controller at high speed through the system backplane bus. It provides reliable digital data support for unit start-stop control, operation status monitoring, fault diagnosis, and safety interlock protection.

As the main digital input module of the Mark VIe series, the DS200GDPAG1ALF has core advantages including 32-channel high-density acquisition, wide voltage compatibility, high anti-interference performance, and redundant design. It can realize centralized acquisition of large-scale digital signals without additional expansion racks, effectively improving the integration and reliability of the control system. It is widely used in large gas turbine/steam turbine control systems in fields such as thermal power generation, petrochemical industry, metallurgy, and marine power. Typical application scenarios include fuel valve status acquisition of gas turbines in thermal power plants, pressure switch signal monitoring of compressors, speed interlock signal acquisition of generators, and unit safety shutdown signal capture. The module features seamless compatibility with the Mark VIe system, 32-channel high-density acquisition, wide-range voltage adaptation, industrial-grade anti-interference, and redundant fault tolerance. It can adapt to harsh industrial environments such as high temperature, high vibration, and strong electromagnetic interference, fully meeting the extreme requirements of large rotating machinery for real-time performance, reliability, and stability in digital signal acquisition.

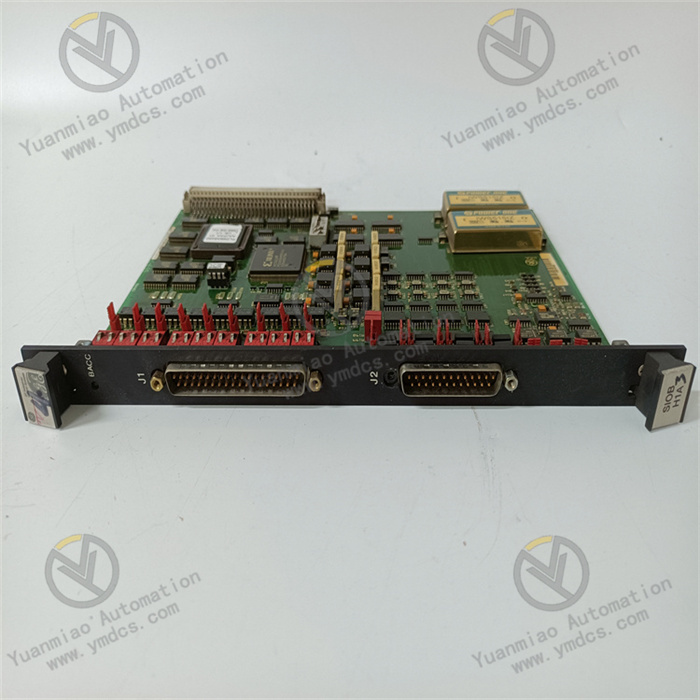

Adopting the VME64x architecture specifically designed for the GE Mark VIe control system, it achieves hardware-level deep compatibility with the system, significantly improving deployment efficiency and operational reliability. The module can be directly inserted into the VME64x backplane of the Mark VIe system's standard rack, enabling high-speed data interaction with the controller through the backplane bus without additional communication adapters or transfer cables. Physical installation only requires two steps: rack insertion and signal wiring. After being connected to the system, the controller can automatically identify the module model, firmware version, and channel configuration information via the backplane bus, eliminating the need for engineers to manually add devices. The real-time status of the module and 32 channels can be directly displayed in the Mark VIe Control Studio software, simplifying the equipment management process. It supports hot swapping, compliant with the Mark VIe system's hot swap specifications, allowing the module to be directly plugged in/out for maintenance or replacement without shutting down the unit. Combined with the system's redundant design, it enables "zero-downtime" maintenance, making it particularly suitable for control systems of critical equipment such as gas turbines and generators that cannot be easily shut down.

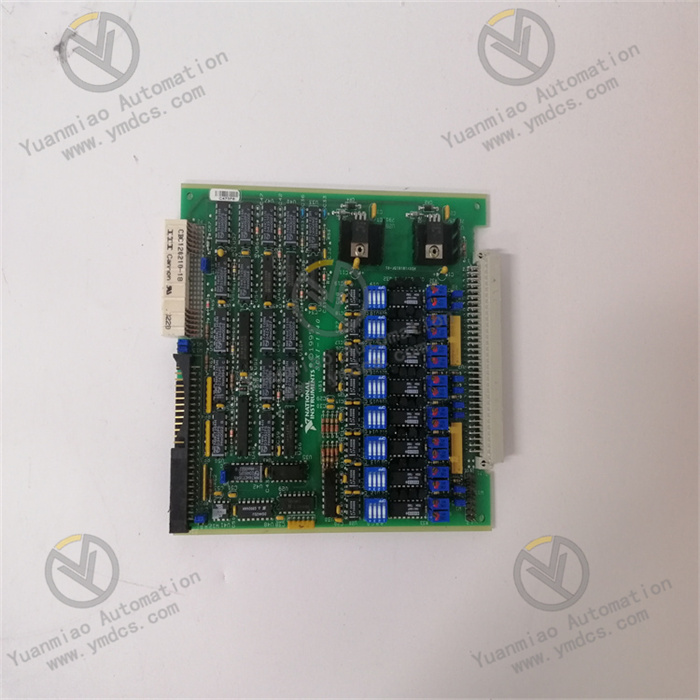

With a 32-channel centralized acquisition design, it realizes synchronous acquisition of 32 digital signals on a single module. Compared with traditional 16-channel modules, it reduces the number of modules and rack space occupation by 50%, significantly improving system integration. For large gas turbine control systems (requiring acquisition of hundreds of digital signals), only 3-4 DS200GDPAG1ALF modules are needed to complete signal acquisition, whereas 6-8 16-channel modules would be required. This not only reduces rack slot occupation but also lowers the procurement and installation costs of auxiliary components such as cables and terminal blocks. The module adopts a grouped design with 8 channels per group, and each group is equipped with independent common terminals and power supply circuits, enabling grouped acquisition of signals with different voltage levels (e.g., the first group acquires DC 24V signals, and the second group acquires DC 125V signals) without additional isolation modules, improving acquisition flexibility. The 32 channels support parallel acquisition, with a response time of ≤1ms per channel, enabling synchronous capture of changes in key status signals of the unit. For example, changes in the status of 32 valves during the start-stop process of a gas turbine can be synchronously acquired, providing synchronous data support for the precise control of the control system.

It supports two types of digital signal input: dry contacts and wet contacts, and wet contacts are compatible with multiple voltage levels of DC 24V/48V/125V. This allows flexible adaptation to the signal output types of different on-site equipment, significantly improving the module's versatility. In dry contact mode, the module can directly acquire passive contact signals from limit switches, pressure switches, etc., and provide working power for the contacts through independent external power supply circuits per group, adapting to traditional sensors without built-in power supplies. In wet contact mode, it can directly acquire active level signals from PLC outputs, solenoid valve feedback, etc., compatible with both PNP and NPN output types, and no need to distinguish signal polarity (the module has a built-in polarity protection circuit). For example, in the gas turbine control system of a thermal power plant, channels 1-8 can be configured in dry contact mode to acquire pressure switch signals, channels 9-16 in DC 24V wet contact mode to acquire solenoid valve feedback, and channels 17-32 in DC 125V wet contact mode to acquire high-voltage cabinet status signals. The 32 channels enable centralized acquisition of multi-type and multi-voltage level signals, adapting to diverse scenarios without replacing the module.

Adopting multiple industrial-grade isolation and anti-interference designs, it has excellent electromagnetic compatibility and environmental adaptability, and can operate stably in the strong interference environment of large power equipment. The module internally adopts a triple isolation architecture of "optoelectronic isolation between channels + electrical isolation between groups + high-voltage isolation between channels and backplane". The isolation voltage between channels reaches 1500VAC, and the isolation voltage between channels and the backplane reaches 2500VAC, which can effectively resist signal crosstalk between different channels and external high-voltage shocks. The internal circuit adopts an EMC (Electromagnetic Compatibility) enhanced design, and through technologies such as filter circuits and shielded housings, it complies with IEC 61000-4-2/3/4/5/6 standards. It can work normally near strong electromagnetic interference sources such as frequency converters and generators, with a signal misjudgment rate of ≤0.001%. The housing is made of die-cast aluminum alloy with an anti-corrosion coating, featuring good vibration resistance, shock resistance, and corrosion resistance. It can adapt to the high-temperature, high-vibration, and dusty environment of gas turbine rooms, with an operating temperature range of 0℃-65℃, and can operate stably without additional heat dissipation devices.

Using high-speed signal acquisition circuits and optimized signal processing algorithms, it achieves high-precision and fast response of digital signals, ensuring the real-time control requirements of large power equipment control systems. The response time of each channel of the module is ≤1ms, and the sampling rate can reach 1000Hz, enabling rapid capture of status changes of on-site equipment. For example, changes in the on/off status of gas turbine fuel valves can be acquired and transmitted to the controller within 1ms, providing a guarantee for the rapid interlock response of the control system. It has a built-in configurable filter time constant (0.1ms-10ms), allowing engineers to flexibly adjust filter parameters according to the interference situation of on-site signals to balance fast response and anti-interference. For example, for indoor signals with less interference, the filter time can be set to 0.1ms to ensure fast response; for outdoor signals with more interference, the filter time can be set to 10ms to filter out interference signals. It supports signal edge detection function, which can accurately capture the rising and falling edges of signals. Combined with controller logic, it can realize precise timing of equipment actions and status judgment. For example, by detecting the edge time of valve on/off signals, it can calculate whether the valve action time meets the process requirements.

Integrating channel-level and module-level comprehensive fault diagnosis functions, it can quickly locate fault points and issue timely early warnings, significantly reducing operation and maintenance costs and fault handling time. The module has multiple diagnostic capabilities such as channel open circuit, short circuit, overvoltage, module power supply fault, and bus communication fault. When a signal line short circuit or overvoltage occurs in a certain channel, the module can detect the fault within 1ms and feed it back in the following ways: first, light up the red status light of the corresponding channel to visually indicate the faulty channel; second, transmit fault information (including channel number, fault type, and occurrence time) to the controller through the backplane bus; third, output a signal through the built-in fault alarm dry contact of the module to trigger an audible and visual alarm. Engineers can view fault details and historical fault logs (capable of storing 1000 fault records) in real time through the Mark VIe Control Studio software, without the need to check wiring and equipment channel by channel, reducing fault troubleshooting time by more than 80%. It supports online fault self-recovery function, and for temporary faults caused by instantaneous interference, the module can automatically resume normal operation without manual intervention.

It supports the redundant configuration function of the Mark VIe system, and through a dual-module hot standby design, it significantly improves the reliability and fault tolerance of large power equipment control systems. In redundant configuration mode, two DS200GDPAG1ALF modules work in parallel, acquiring the same on-site signals and transmitting them to the controller. The controller compares and judges the two signals through a redundant management algorithm. If one of the modules fails, the controller can automatically switch to the signal of the other module within 10ms, realizing "disturbance-free" switching and ensuring the normal operation of the system. The module has a fault isolation function: a fault in a single channel will not affect the normal operation of other channels, and a fault in a single module will not affect the operation of the other redundant module, which can effectively avoid system shutdown caused by "single point of failure". It supports online module firmware upgrade function, allowing engineers to remotely upgrade the module firmware through software without disassembling the module. During the upgrade process, the redundant module can maintain normal operation without affecting the system operation.

![]()