Description

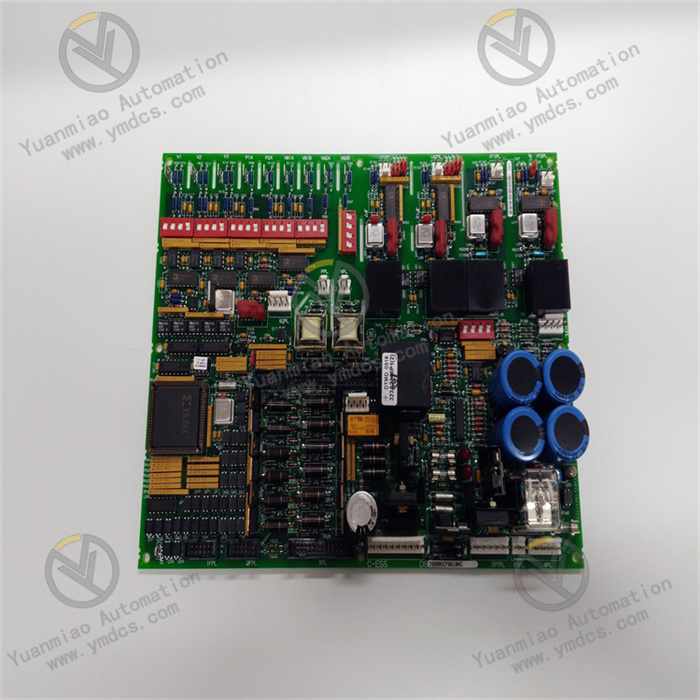

GE IS215UCVDH5A

I. Product Overview

GE IS215UCVDH5A is a modular I/O processing board developed specifically for control systems. As a key hub connecting sensors, actuators, and main control units, its core value lies in high-precision conditioning, real-time transmission, and centralized management and control of multiple types of signals during turbine operation. It is suitable for automated drive scenarios of gas turbines, steam turbines, and wind turbines, and serves as the "signal hub" ensuring unit operating condition monitoring and the execution of control commands.

This module adopts a three-board integrated computer unit design and achieves high-speed communication with the system I/O board via the VME bus. Compared with the previous-generation Mark V series products, it adds wind turbine control adaptation capability, further expanding the application boundaries in the new energy field. Its enhanced PCB conformal coating and industrial-grade structural design enable it to adapt to harsh environments such as vibration and oil contamination in turbine rooms, making it an important carrier of GE Speedtronic's patented control technology.

II. Core Technical Parameters

(I) Hardware and Computing Foundation

| Parameter Category | Specific Specifications |

|---|---|

| Core Processor | 300MHz AMD K6 processor, supporting multi-task real-time processing |

| Storage Configuration | 16MB DRAM (running memory) + 8MB Flash (program storage), ensuring stable operation of control programs |

| Operating System | QNX real-time operating system, suitable for industrial-grade real-time control needs |

| Physical Specifications | Dimensions: 10.5×7.75×3.5 inches (H×D×W), Weight: 3 pounds 10 ounces, suitable for VME standard rack mounting |

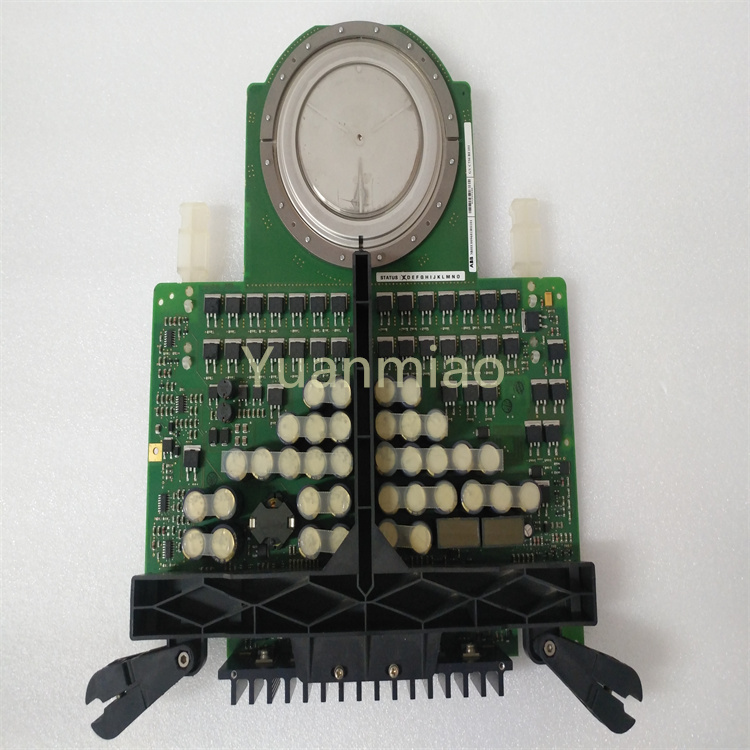

(II) Signal Conditioning and I/O Capability

As a core analog I/O processing unit, its signal processing covers all-dimensional parameters of turbine operation:

- Signal Input Conditioning:

- Supports LVDT/LVDR position signals (e.g., governor valve displacement), thermocouple temperature signals (e.g., exhaust temperature), and 4-20mA industrial signals (e.g., fuel pressure, compressor stall detection);

- Compatible with vibration sensor inputs (±10V DC), pulse signals (e.g., speed pulses), and generator/line electrical signals, with an input accuracy of ±0.1% FS.

- Signal Output Drive:

- Provides servo valve drive signals and relay control outputs, supporting two output current ranges of 20mA/200mA (configured via J5/J6 jumpers);

- Output signals undergo isolation and amplification processing, with a common-mode interference voltage resistance of ≥±250V, suitable for control needs of mainstream servo valves such as Moog.

- Cold-Junction Compensation: Realizes cold-junction compensation of thermocouple signals through the JA connector of the TBQA board, with a temperature measurement error of ≤±0.5℃.

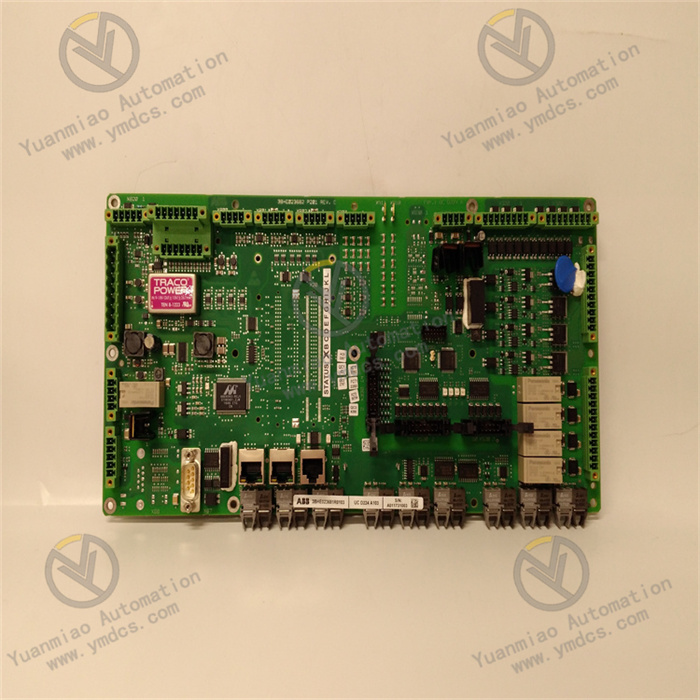

(III) Communication and Interface Configuration

- Bus Interfaces: VME bus (core communication), 2 IS bus ports, enabling high-speed data interaction with I/O core modules, with a communication delay of ≤1ms;

- External Communication: 2 Genius terminals, 2 COM ports (RS232), 1 Ethernet port (supporting UDH protocol), 1 LPT1 parallel port;

- Signal Connection: Transmits conditioned signals with the STCA/TCQE board via the 3PL connector; realizes generator signal interaction with the TCQC board via the JE connector; receives position and vibration signals via the JF/JG interfaces.

(IV) Environmental and Reliability Parameters

- Protection Design: The entire PCB is covered with a conformal protective coating, which is oil-proof, dust-proof, and moisture-proof, adapting to the harsh environment of turbine rooms;

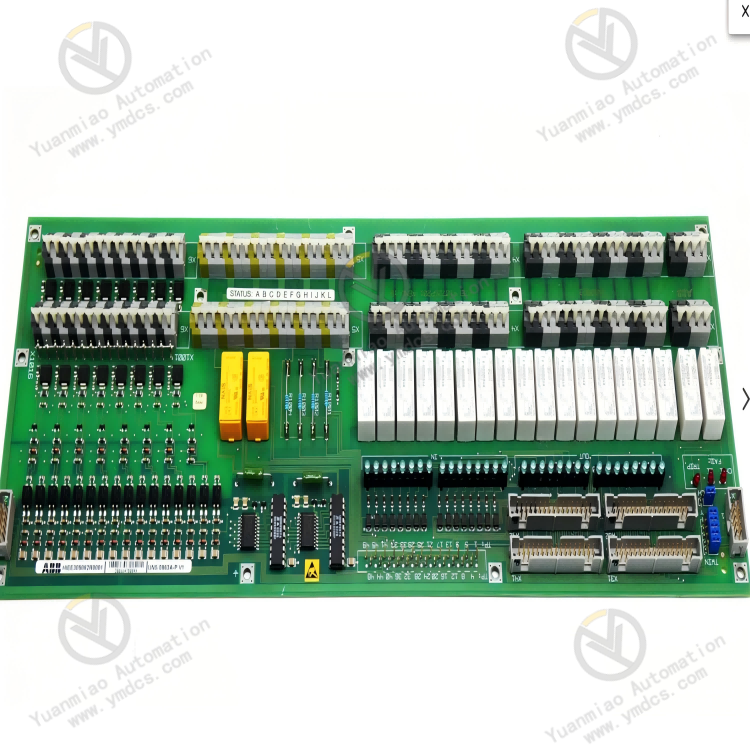

- Anti-Interference Performance: Passes industrial-grade electromagnetic compatibility tests and can resist electromagnetic interference generated by motors and frequency converters;

- Indication Function: Equipped with 20 status indicator LEDs to provide real-time feedback on operating conditions such as power supply, communication, and signal abnormalities.

III. Functional Features

(I) Centralized Conditioning of All Types of Signals, Simplifying System Architecture

The module integrates multi-dimensional signal processing functions required for turbine control, replacing the complex traditional solution of "discrete signal conditioning modules + I/O modules". For example:

- Scales and conditions 4-20mA fuel flow pressure signals, and directly outputs standardized data to the main control unit;

- Processes LVDT position signals and servo valve output signals to realize the integration of the closed-loop control link for governor valve opening;

- Transmits generator and line signals via the JE connector, simplifying the wiring and equipment configuration for electrical parameter monitoring.

This design reduces the number of control cabinet equipment by 30% and fault nodes by 40%, improving system reliability.

(II) High-Speed Bus Communication, Ensuring Real-Time Control

Relying on the VME bus and QNX real-time operating system, the module achieves full-link low latency for signal acquisition, processing, and transmission:

- The response time from collecting signals from vibration sensors to uploading data to the main control unit is ≤5ms, meeting the real-time requirements for turbine shaft vibration monitoring;

- Completes the output of servo valve drive signals within 100μs after receiving main control commands, suitable for scenarios requiring rapid adjustment of governor valves;

- The dual IS bus ports support redundant communication, avoiding signal interruption caused by a single bus failure.

(III) Flexible Configuration and Diagnosis, Adapting to Multi-Scenario Requirements

- Hardware Jumper Configuration: Select the milliamp output circuit via J1/J2 jumpers, and enable the RS232 port card test function via J7 jumpers, adapting to different sensor and actuator specifications;

- Status Monitoring: 20 LED indicator lights display statuses such as power supply, communication, and signal abnormalities in real time, and cooperate with the reset switch to achieve rapid fault diagnosis;

- Cross-Series Compatibility: Although designed for the Mark VI series, it can be adapted to the I/O cores R1/R2/R3 of the Mark V system, reducing the upgrade cost of old units.

IV. Application Scenarios

(I) Traditional Energy Field: Gas/Steam Turbine Control

- Gas Turbines: Conditions compressor stall detection signals, fuel pressure signals, and exhaust temperature signals; drives fuel servo valves and IGV vane actuators; cooperates with the main control unit to realize combustion efficiency adjustment and load control; transmits generator electrical signals via the JE connector to ensure stable power generation quality.

- Steam Turbines: Processes LVDT governor valve position signals and shaft vibration signals; outputs servo valve control commands to achieve precise speed adjustment of 3000rpm/3600rpm; monitors main steam pressure signals to avoid the risk of overpressure operation.

(II) New Energy Field: Wind Turbine Control

As a key module of the Mark series adapted for new energy, its main functions include:

- Conditions pulse signals (such as wind speed and impeller speed) and vibration signals, and uploads them to the main control unit for pitch control;

- Drives hydraulic actuators to adjust blade angles, adapting to stable power output under wind speed fluctuations;

- Uploads operating data to the wind farm monitoring system via the Ethernet port to support remote operation and maintenance.

(III) Upgrade and Transformation of Old Units

For existing turbine units using the Mark V system, the IS215UCVDH5A can directly replace old I/O modules to achieve:

- Improved signal processing accuracy (e.g., temperature measurement error reduced from ±1℃ to ±0.5℃);

- Added Ethernet communication function, adapting to modern HMI and historian databases;

- Enhanced protective coating extends module service life and reduces failure rates in humid, hot, and oily environments.