Description

GE IS230STAOH2A

The GE IS230STAOH2A is a high-performance industrial-grade analog input module, which is part of the core I/O component matrix of GE's Mark VIe Distributed Control System (DCS) and Speedtronic turbine control system. Its core positioning is to serve as an "accurate sensing hub" for analog signal acquisition in industrial sites. It focuses on high-precision and high-stability acquisition of analog signals such as voltage and current, covering sensing signals of key process parameters including pressure, flow rate, liquid level, vibration, and rotational speed. Through advanced signal conditioning, wide-range adaptation, and enhanced anti-interference design, it converts continuously changing physical quantities on-site into digital signals recognizable by the system, providing reliable front-end data support for closed-loop control, condition monitoring, and safety interlocking of core industrial processes such as turbine speed control, boiler combustion optimization, and generator power regulation.

The application scenarios of this module extensively cover fields with strict requirements for the accuracy, real-time performance, and anti-interference capability of analog signal acquisition, including:

- Power Energy: Acquisition of turbine speed signals in thermal power units, acquisition of boiler drum water level signals, monitoring of generator stator voltage signals, and acquisition of induced draft fan flow signals.

- Petrochemical Industry: Acquisition of reactor pressure signals, monitoring of distillation tower liquid level signals, acquisition of crude oil transportation flow signals, and acquisition of catalyst injection quantity signals.

- Metallurgy and Steel: Acquisition of blast furnace top pressure signals, monitoring of converter molten pool temperature analog signals, acquisition of rolling mill rolling force signals, and acquisition of continuous caster mold liquid level signals.

- Heavy Equipment: Acquisition of pressure signals of large extruders, monitoring of wind turbine speed signals, and acquisition of oil pressure signals of ship propulsion systems.

As a dedicated analog input module for GE's high-end control systems, it can not only realize parallel and efficient acquisition of multi-channel signals but also seamlessly collaborate with system controllers, supporting flexible functions such as signal calibration, range conversion, and alarm logic configuration. It is a key hardware foundation for building high-reliability industrial process control systems.

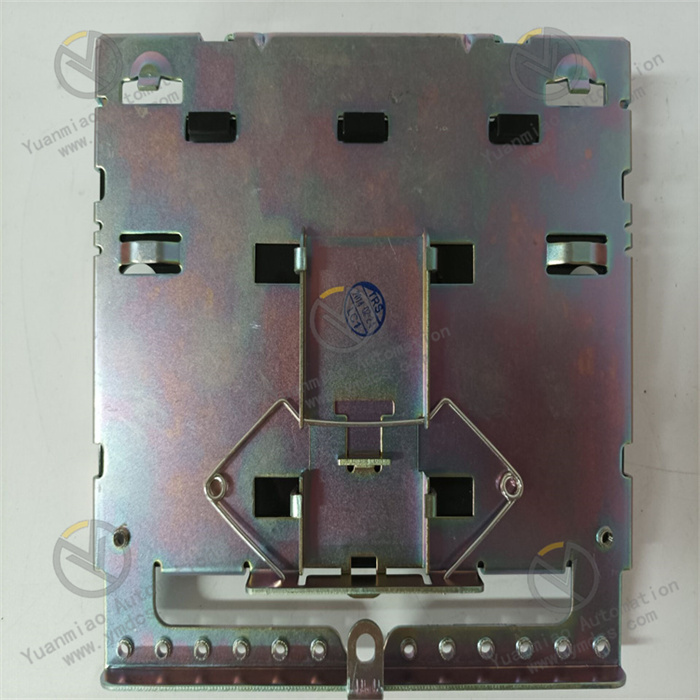

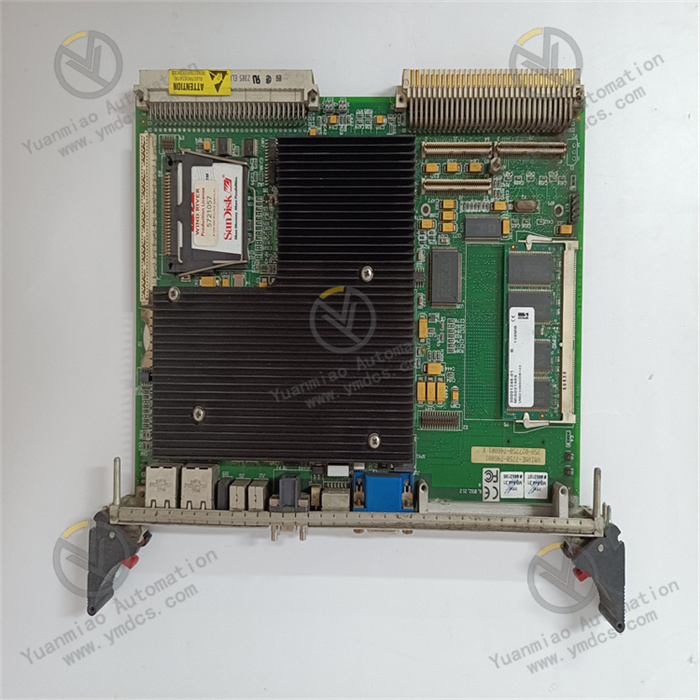

In terms of hardware architecture and system compatibility, the GE IS230STAOH2A adopts a standardized modular design, which can be seamlessly integrated into the IC695 series I/O racks of the GE Mark VIe control system and Speedtronic turbine control cabinets, occupying only one standard I/O module slot. It achieves millisecond-level data interaction with the system controller through a high-speed backplane bus. The module is compatible with GE CIMPLICITY HMI and iFIX monitoring software, supporting the configuration of key parameters such as channel signal type, range, sampling cycle, filtering parameters, and alarm thresholds through a graphical interface, enabling rapid system integration without writing underlying code. Relying on its industrial-grade reinforced design, the module uses wide-temperature components, a metal shielded enclosure, and an anti-vibration structure, allowing stable operation in complex industrial site conditions with high temperature, high humidity, dust, strong electromagnetic interference, and high vibration, thus ensuring the continuity and accuracy of analog signal acquisition.

The GE IS230STAOH2A adopts a 16-channel high-density integrated design, enabling parallel and synchronous acquisition of 16 independent analog signals within the space of one standard I/O slot. Compared with traditional 8-channel modules, the acquisition density is increased by 100%, which can significantly reduce the number of rack slots occupied, lowering system hardware costs and cabinet space requirements. The module has rich signal adaptation capabilities; switching and configuration between current signals (4mA~20mA, 0mA~20mA) and voltage signals (0V~5V, 1V~5V, 0V~10V) can be completed via software. It can adapt to the access needs of different types of on-site sensors without replacing the module. For example, in a thermal power unit monitoring scenario, channels 1-4 can be configured as 4mA~20mA current input (connected to pressure transmitters), channels 5-8 as 0V~10V voltage input (connected to liquid level sensors), and channels 9-16 as 1V~5V voltage input (connected to speed sensors), realizing centralized acquisition and unified management of multi-type process parameters and greatly improving the flexibility of on-site configuration. At the same time, the module uses a 16-bit high-precision ADC conversion chip combined with factory calibration technology, ensuring that the measurement accuracy of current signals reaches ±0.02% FS and that of voltage signals reaches ±0.03% FS, which can accurately capture small changes in signals and provide data support for process optimization.

The module adopts a dual anti-interference mechanism of "hardware RC low-pass filtering + software digital filtering", which can effectively suppress various electromagnetic interferences in industrial sites. At the hardware level, each input channel is equipped with an independent RC low-pass filter circuit, and filtering parameters can be flexibly configured according to signal frequency to specifically filter out 50Hz/60Hz power frequency interference and high-frequency radiation interference generated by frequency converters and high-voltage motors. At the software level, it supports independent configuration of digital filtering frequency within the range of 0.1Hz~100Hz, and the filtering intensity can be accurately adjusted according to signal characteristics. For example, 100Hz high-frequency filtering can be configured for rapidly changing pressure fluctuation signals, and 0.1Hz low-frequency filtering for slowly changing liquid level signals, ensuring both real-time signal response and avoiding measurement fluctuations caused by interference. The high-strength photoelectric isolation design of 2500Vrms is adopted between channels, and 2000Vrms isolation is adopted between channels and the backplane bus, which can effectively block common-mode interference and differential-mode interference between channels. Even if a short circuit or overvoltage fault occurs in one channel, it will not affect the normal acquisition of other channels, further enhancing the anti-interference stability of the system.

The module supports 16-channel synchronous sampling function. The sampling cycle can be flexibly configured via software within the range of 1ms~1000ms, with a default sampling cycle of 50ms and a maximum high-speed sampling of 1ms. It can accurately capture transient signals such as turbine speed fluctuations and reactor pressure mutations, providing millisecond-level data support for key logics such as system emergency interlocking and closed-loop control, and avoiding safety accidents or process deviations caused by signal delays. The module performs data interaction with the GE Mark VIe controller through a high-speed backplane bus, with a data transmission rate of ≥100Mbps. The collected digital signals can be uploaded to the controller within 1ms, ensuring the real-time performance and accuracy of control logic operations. For example, in a rolling mill rolling force monitoring scenario, the module synchronously collects signals from 4 rolling force sensors at a 10ms sampling cycle. After real-time upload to the controller, the controller can quickly adjust the roll pressure to ensure the uniformity of steel plate thickness, meeting the monitoring and control needs of high-speed industrial production scenarios.

The module has a fault diagnosis coverage rate of 99.9%, integrating dual diagnosis mechanisms at the channel level and module level, enabling precise fault location and rapid troubleshooting. Channel-level diagnosis can automatically identify faults such as signal open circuit (e.g., loose sensor wiring, wire breakage), short circuit (e.g., signal wire short-circuited to ground), and signal over-range (e.g., abnormal over-limit of process parameters). Module-level diagnosis can real-time monitor hardware issues such as abnormal power supply voltage, backplane communication failure, isolation circuit failure, and ADC conversion failure. When a fault occurs, the module immediately generates a standardized fault code (e.g., E001 for channel 1 open circuit, E002 for signal over-range, F001 for module power fault) and issues hierarchical alarms through local LED indicators (yellow light flashes for channel faults; red light stays on for module faults). Meanwhile, it uploads fault information (faulty channel, fault type, occurrence time, fault code) to the controller and upper-level monitoring system, clearly indicating the fault location and handling suggestions (e.g., "Channel 5 is short-circuited, please check the sensor wiring and circuit"), significantly shortening the fault troubleshooting time for operation and maintenance personnel and improving operation and maintenance efficiency.

The module supports 1:1 hot redundancy configuration. The main and standby modules achieve real-time data synchronization through a dedicated redundant communication link, with synchronized content including key information such as 16-channel acquisition data, configuration parameters, and fault status, and a synchronization delay of ≤1ms, ensuring complete data consistency between the main and standby modules. During normal operation, the main module performs signal acquisition and data upload functions, while the standby module monitors the operating status of the main module in real time and synchronizes data. When the main module encounters abnormal conditions such as power failure, communication interruption, or batch channel faults, the standby module can automatically complete undisturbed switching within 15ms and take over all acquisition functions. During the switching process, no acquisition data is lost and no signal output fluctuation occurs, ensuring uninterrupted monitoring and control of key equipment such as turbines and boilers. The module has channel-level fault isolation capability; when a single channel fails, it is automatically marked as "faulty state" and shielded, without participating in data acquisition and upload, and without affecting the normal operation of the other 15 channels. Additionally, it supports remote disabling/enabling of faulty channels via software, improving the system's fault tolerance and operational stability.

The module is compatible with mainstream monitoring software such as GE CIMPLICITY HMI and iFIX, supporting full-parameter configuration through a graphical configuration interface, including channel signal type, range, sampling cycle, filtering frequency, alarm threshold, and calibration parameters. No underlying code writing is required, making the configuration process intuitive and efficient—even beginners can quickly get started. The integration and debugging cycle is shortened by more than 60% compared with traditional modules. The software has built-in rich industry application templates (such as turbine speed monitoring template, reactor pressure control template, and boiler water level monitoring template), which include preset channel configurations and alarm logics. After importing the template, integration can be completed by only fine-tuning according to on-site sensor parameters, further improving deployment efficiency. The module seamlessly connects with the GE Mark VIe controller through a standardized backplane bus, supporting the controller's online diagnosis, parameter modification, firmware upgrade, and zero/full-scale calibration of the module. Maintenance operations can be completed without shutdown, reducing production interruption time. Meanwhile, it supports the Modbus TCP communication protocol, enabling flexible integration into third-party DCS systems and improving the compatibility of cross-brand system integration.

Based on the core workflow of "signal access - signal conditioning - signal acquisition - data processing - data upload - fault diagnosis", the GE IS230STAOH2A realizes high-precision and high-reliability acquisition of analog signals through the collaboration of hardware circuits and software logic. The specific working mechanism is as follows:

Analog signals (current or voltage) output by on-site sensors (such as pressure transmitters, liquid level sensors, and speed sensors) are connected to the module through 16 independent input terminals and first enter the signal conditioning unit. According to the software-configured signal type, the conditioning unit automatically switches the signal processing circuit: for current signal input, the current signal is converted into a voltage signal through a precision sampling resistor; for voltage signal input, it directly enters the signal amplification link. The conditioning unit has a built-in high-precision instrumentation amplifier that performs linear amplification on weak signals. The amplification factor can be automatically adjusted according to the configured range to ensure the signal amplitude is within the optimal input range of the ADC conversion unit, improving conversion accuracy. The amplified signal first passes through the hardware RC low-pass filter circuit to filter out power frequency interference and high-frequency noise, and then is sent to the photoelectric isolation unit to achieve electrical isolation between the input channel and the module's internal core circuit, preventing external high-voltage and strong interference signals from invading and ensuring the safe and stable operation of the core circuit.

The analog signal after isolation and filtering is sent to a 16-bit high-precision ADC conversion unit. The ADC unit performs synchronous sampling of the 16-channel signals according to the configured sampling cycle (minimum 1ms), converts the analog signal into a digital signal, and stores it in the temporary data register. Subsequently, the data processing unit performs multi-stage processing on the digital signals in the temporary register: first, it performs scaling conversion according to the configured signal type and range, converting the digital signal into the corresponding physical quantity (such as pressure value, liquid level value, speed value); then, it performs software digital filtering, eliminating glitches and interference noise in the signal according to the configured filtering frequency of each channel to obtain stable valid data; next, it conducts continuity verification on the data. If the signal change rate is detected to exceed the configured threshold or the signal is out of the range, the signal is marked as "abnormal" and an alarm is triggered; finally, the system error is corrected through a calibration algorithm to further improve the measurement accuracy.

The processed valid data is uploaded to the GE Mark VIe controller through the high-speed backplane bus at a fixed cycle (synchronized with the sampling cycle), providing accurate data support for the controller's logical operations, closed-loop control, process optimization, and alarm handling. In the redundancy configuration mode, the data processing unit of the main module synchronizes information such as 16-channel acquisition data, configuration parameters, and fault status to the redundant data register of the standby module in real time through a dedicated redundant communication link, with a synchronization frequency of 1000 times per second, ensuring complete data consistency between the main and standby modules. The redundancy monitoring unit of the standby module compares the operating status and data of the main and standby modules in real time; if abnormal data, communication interruption, or hardware failure of the main module is detected

![]()