Description

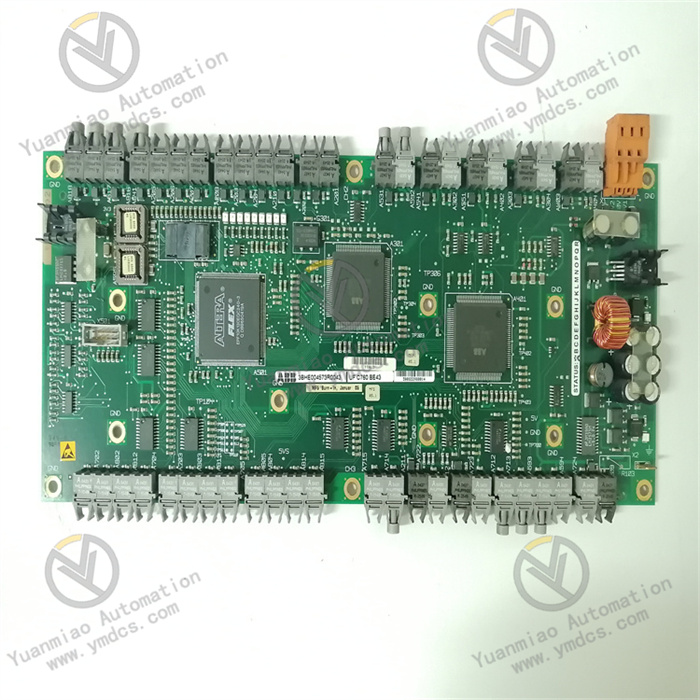

VMIVME-7750-746000/350-027750-746000 K

Overview

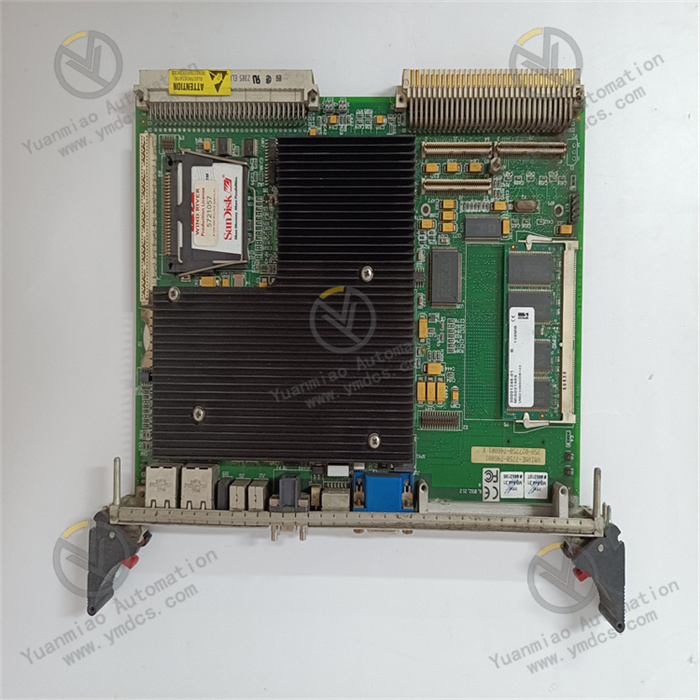

The Abaco Systems VMIVME-7750-746000/350-027750-746000 K is a high-performance VMEbus Single-Board Computer (SBC). The product entered the Restricted Production Phase (RPP) on February 5, 2009. Based on the mature VME (VersaModule Eurocard) bus architecture, it is widely used in industrial control, data acquisition, and other fields, renowned for its high performance, reliability, and excellent customizability. The device features a rugged single-slot design with passive cooling, enabling stable operation in harsh industrial environments such as high temperature, high humidity, and strong electromagnetic interference, ensuring continuous and reliable system performance.

This single-board computer integrates an Intel Pentium III processor with advanced chipset technology, delivering powerful processing capabilities for various complex tasks. With rich memory options, diverse I/O interfaces, and flexible expansion capabilities, it excels in numerous fields such as industrial automation, data acquisition systems, and image processing, making it an ideal choice.

Functional Features

(1) Powerful Processing Performance

Equipped with an Intel Pentium III processor up to 1.26GHz, adopting the advanced x86 architecture with 32-bit addressing and a 64-bit data bus. Its superscalar architecture, combined with dynamic branch prediction technology, accurately predicts program execution paths, effectively reducing latency during instruction execution. Independent instruction and data caches greatly accelerate data reading and storage speeds. With MMX technology, it can execute three instructions per clock cycle, excelling in multitasking and complex algorithm operations, efficiently processing real-time data to fully meet the rigorous requirements of industrial automation, data acquisition, and other fields for high-speed data processing.

(2) Flexible and Efficient Memory Configuration

Supports up to 512MB of PC133 SDRAM, allowing users to flexibly adjust memory capacity via a 144-pin SODIMM slot according to actual application needs. The memory uses dual-port DRAM connected to the VMEbus, significantly improving data transfer efficiency during multi-device communication, ensuring the system maintains smooth and stable operation when running memory-intensive applications without being affected by memory bottlenecks.

(3) Diverse I/O Interfaces

- VMEbus Interface: Strictly compliant with VMEbus Rev. C.1 standard, enabling high-speed data exchange for multi-processor systems. In the system, it can act as a master device to initiatively initiate data transmission or as a slave device to respond to requests from other devices. Through transparent PCI-VME bridging technology, it collaborates with other VME devices to ensure seamless data transmission across the entire VMEbus ecosystem, providing a solid foundation for building complex industrial control systems.

- Ethernet Interface: Onboard Ethernet interface supports high-speed network connections to meet the device's data interaction needs with external networks. It also enables remote boot via relevant protocols, facilitating remote system deployment and management—particularly suitable for distributed industrial control systems and remote data acquisition scenarios, allowing engineers to complete device boot and basic configuration without on-site presence.

- Storage Interface: Features an IDE interface for convenient connection of local storage devices such as hard drives, used to store system files, applications, and large volumes of data. Some models also support CompactFlash storage, which offers advantages like small size and strong shock resistance, suitable for applications with high space and stability requirements.

- Expansion Interface: Equipped with a PCI-X 66MHz PMC expansion slot, allowing users to insert various custom I/O modules (e.g., serial port modules, USB modules, analog/digital I/O modules) based on specific application scenarios, greatly expanding device functions. This enables flexible adaptation to different application scenarios and needs, whether adding extra communication interfaces or performing special data acquisition and control via PMC modules.

(4) Wide Operating System Compatibility

Supports multiple real-time and general-purpose operating systems, including VxWorks, Linux, Windows, etc. This broad compatibility allows flexible deployment of the device in different application environments—from industrial control scenarios requiring extremely high real-time performance (where millisecond-level response is crucial) to general computing scenarios needing rich software ecosystem support—enabling suitable OS adaptation and reducing user development and usage costs.

(5) High Precision and Reliability

Adopts industrial-grade design to adapt to harsh environments. Equipped with high-precision A/D converters for accurate analog signal conversion, and rich diagnostic functions to promptly detect potential issues during device operation, ensuring stable device performance.

(6) Flexible Configuration

Supports multiple configuration methods, allowing users to flexibly choose installation and wiring methods according to actual conditions to meet installation requirements for different projects.

(7) High-Speed Data Acquisition

Supports high-speed triggering and real-time monitoring, capable of quickly capturing and processing rapidly changing data, suitable for application scenarios with strict data acquisition speed requirements.

(8) Strong Compatibility

Complies with VMEbus standards and supports multiple communication protocols (e.g., Ethernet, RS-485), facilitating data communication and system integration with other devices.

Technical Parameters

| Category | Detailed Specifications |

|---|---|

| Processor | Intel Pentium III, up to 1.26GHz with 512KB L2 cache |

| Memory | Up to 512MB PC133 SDRAM |

| Storage | IDE interface; some models support CompactFlash storage (e.g., 64MB CompactFlash) |

| Network | Onboard Ethernet interface, supports remote boot, compatible with 10BaseT and 100BaseTX |

| Expansion | One PCI-X 66MHz PMC expansion slot |

| Power Supply | +5V DC input, passive cooling design, low power consumption |

| Environmental | Operating temperature: Set per industrial standards (typically a wide range for harsh environments); Storage temperature: Meets industrial storage requirements; Humidity: Complies with industrial environmental humidity standards (non-condensing) |

| Others | Internal AGP SVGA controller with 4MB display cache; supports VGA, PS/2 keyboard and mouse ports, USB 2.0 interfaces, serial ports, parallel ports |

Working Principle

(1) System Boot Process

After the device is powered on, the onboard power management circuit first stabilizes the input +5V DC voltage to provide pure and stable power supply for all components. The processor then loads the BIOS program from reprogrammable flash memory, and the BIOS comprehensively initializes hardware, including memory self-test, timer setup, I/O interface configuration, etc. After initialization, the system reads and loads the operating system image from a local IDE storage device according to the preset boot order; if remote boot is configured, it can also obtain boot information from a remote server via the Ethernet interface following relevant protocols, completing OS loading and entering normal operation.

(2) Data Processing Flow

During operation, the Pentium III processor parses tasks based on pre-programmed algorithms. When processing real-time data in industrial applications (e.g., data collected from sensors), the processor frequently reads/writes data with SDRAM, retrieving data from memory for computation and writing processing results back to memory. For tasks involving graphic display, the AGP graphics adapter fetches relevant data from memory, processes it, and generates high-quality visual outputs to meet operators' needs for real-time data visualization. The VMEbus coordinates data transfer between the processor and external devices, ensuring accurate data flow across different devices. The Ethernet interface enables data interaction with other network devices via protocol encapsulation/decapsulation, integrating the device into the network environment for data sharing and collaboration.

(3) Bus Architecture Principle

Through transparent PCI-VME bridging technology, the device can act as a system controller or peripheral CPU in multi-processor systems. This bridging technology ingeniously resolves communication differences between the PCI bus and VMEbus, allowing seamless integration of the device into the VMEbus ecosystem. In complex multi-device collaborative environments, it ensures efficient and accurate data exchange between different devices, maintaining overall system stability without data loss or system failures due to bus communication issues.

Operation Guide

(1) Pre-installation Preparations

- Compatibility Check: Carefully verify specifications of the VMEbus slot, including electrical parameters (voltage, current, etc.) and power supply capacity, to ensure full compatibility with the VMIVME-7750-746000/350-027750-746000 K. Differences in VME slot models may lead to abnormal device operation or even damage if mismatched.

- Tools and ESD Protection: Prepare anti-static wristbands, suitable screwdrivers, and other installation tools. During installation, static electricity generated by the human body may cause irreversible damage to precision electronic components on the device, so always wear an anti-static wristband and ensure the installation environment has good ESD protection measures (e.g., anti-static workbench mats).

(2) Module Installation Steps

- Open the VME chassis and locate an empty slot suitable for 6U device installation.

- Precisely align the device's VME interface with the slot, ensuring all pins match the slot's positions, then insert it vertically and smoothly with even force to avoid skew or poor contact. If insertion is difficult, do not force it—check the cause and retry.

- Secure the device to the slot with matching screws, tightening them to prevent loosening due to vibration, which could affect normal operation and data transmission stability.

- Connect power cables correctly and firmly per application needs to avoid power supply issues from loose connections. If using an IDE storage device, connect the corresponding cable; for functional expansion, connect PMC modules and other accessories, paying attention to interface orientation and connection sequence as per the manual.

(3) System Configuration Methods

- Storage and Network Setup: If using local storage, configure the IDE drive in the system (e.g., set boot order, partitions) to ensure proper recognition. For remote boot, set parameters (IP address, subnet mask, gateway, etc.) via the Ethernet interface. Correct parameter configuration is crucial for the device to connect to the network and obtain boot information, testable via the ping command.

- OS and Driver Installation: Select a suitable OS (e.g., VxWorks, Linux) based on application scenarios and install it following the steps. Pay attention to selecting correct hardware drivers, especially for PMC modules—incorrect installation may disable device functions. Refer to Abaco Systems' official documentation for a smooth installation.

(4) Common Fault Troubleshooting

- Boot Failure: First, check power connections and ensure the power indicator is on. Verify flash memory integrity for data corruption/loss using specialized tools. Check BIOS boot order settings and adjust them if incorrect to ensure booting from the correct device.

- Network Issues: Check Ethernet cable connections for looseness, damage, or breakage. Update network drivers, as outdated or corrupted drivers may cause connection failures. Test network device connectivity via ping and verify TCP/IP parameter configurations, re-setting them if incorrect.

- I/O Failures: Check PMC module installation for firm seating and re-plug it to ensure reliable connection. Update PMC module firmware/drivers if necessary, as old versions may have compatibility issues. For unresolved faults, replace faulty components, ensuring compatibility and following correct procedures. Refer to Abaco Systems' official technical documentation or contact customer service for support during troubleshooting.