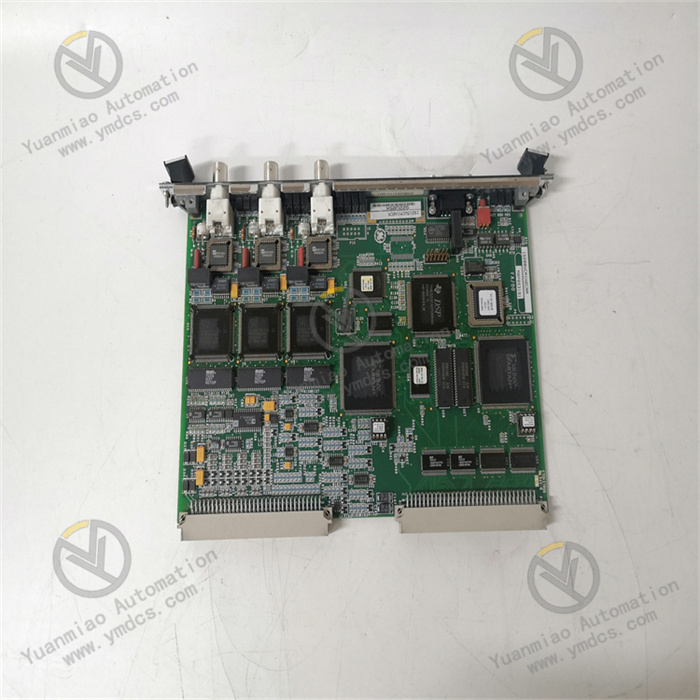

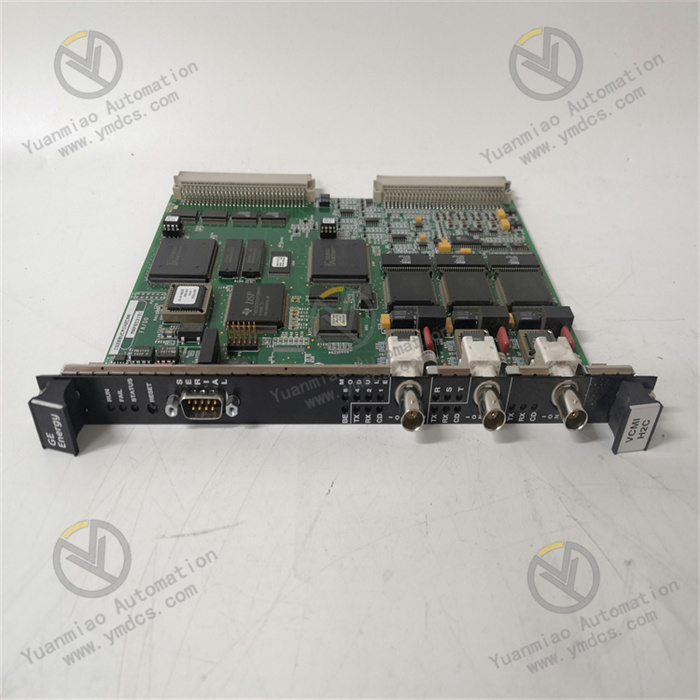

Description

GE IS200VCMIH2CAA

GE IS200VCMIH2CAA is a core control module in digital control systems, specifically designed for scenarios involving core control logic execution, multi-module collaborative scheduling, and precise regulation of key parameters in large-scale steam turbine generator units. It is widely used in fields with strict requirements for steam turbine control reliability, real-time performance, and scalability, such as thermal power generation, combined cycle power generation, and industrial self-owned power plants. As the "control core" of the Mark VIe system, this module integrates a high-performance control core, multi-protocol communication interfaces, a redundant fault-tolerant architecture, and an intelligent diagnostic unit. It can seamlessly connect to I/O modules (e.g., IS200TBCIS2CCD), sensors, actuators, and upper-level monitoring systems within the system, enabling full-process closed-loop control of steam turbines from startup, speed increase, grid connection with load, to shutdown, and providing core control support for the safe and stable operation of the unit.

As a key control node of the Mark VIe series, the IS200VCMIH2CAA is equipped with a multi-core high-performance processor and a real-time operating system, with a control cycle as low as 1ms, enabling it to accurately execute complex control logics such as speed regulation, load distribution, and steam parameter control. It supports cascading of up to 32 extended I/O modules, adapting to the control needs of steam turbine generator units with different capacities ranging from 100MW to 1500MW. Adopting a dual redundant hardware design and multi-level fault-tolerant mechanism, it can achieve uninterrupted operation under harsh working conditions such as high temperature, high humidity, and strong electromagnetic interference. Combined with comprehensive online operation and maintenance functions, it significantly reduces the risk of unplanned unit shutdowns and improves power generation efficiency and operational safety.

High-Performance Control Logic ExecutionEquipped with a TI TMS320C6748 multi-core floating-point Digital Signal Processor (DSP) and an ARM Cortex-A8 main control unit, the processor operates at a frequency of 1GHz, with 512MB DDR3 high-speed cache and 1GB Flash storage. It can run multiple sets of independent control logics simultaneously (e.g., speed PID regulation, load coordination control, steam pressure control). The control cycle can be flexibly configured within the range of 0.1ms-10ms to meet the real-time requirements of different control scenarios. It has a built-in GE-specific ControlST control algorithm library, covering mature control strategies such as steam turbine startup curve control, variable load sliding pressure control, and load rejection protection. It supports users to customize control logics through standardized languages such as Structured Text (ST) and Function Block Diagram (FBD), adapting to the personalized control needs of steam turbines from different manufacturers. In terms of control accuracy, the speed regulation accuracy reaches ±0.01% of the rated speed, and the load regulation accuracy reaches ±0.1% of the rated load, which can effectively improve the operational stability of the unit and energy utilization efficiency.

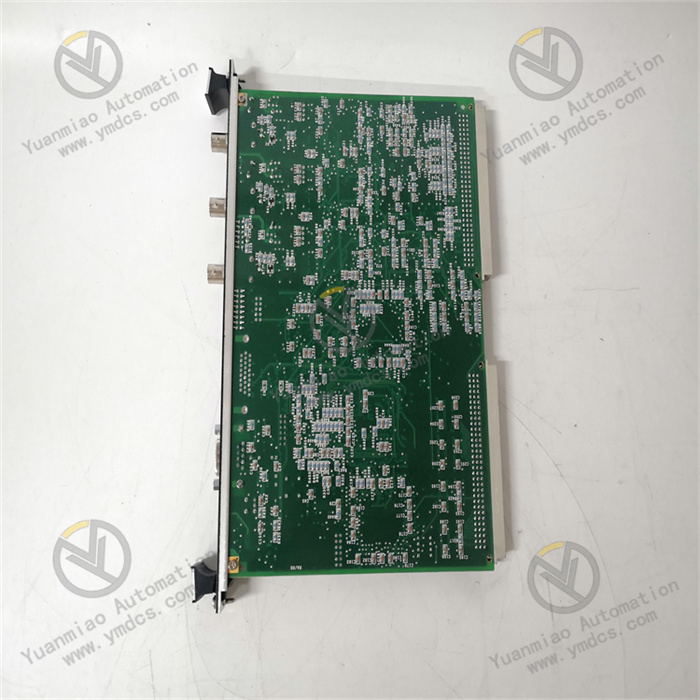

Full Redundant Fault-Tolerant Architecture DesignIt adopts a 1oo2D (1-out-of-2 with Diagnostics) redundant architecture, with built-in dual independent control cores, dual redundant power interfaces, dual redundant communication buses, and dual storage units. The dual control cores execute control logic synchronously and perform real-time cross-validation of calculation results. If data deviation or a single core fault occurs, the built-in diagnostic circuit can complete fault location and isolation within 2ms, and the standby core seamlessly takes over the control task without interruption to control output. The redundant storage units adopt a "Flash+EEPROM" dual-backup design, with dual storage of control programs, parameter configurations, and operation logs, supporting automatic data recovery after faults to ensure the integrity of system configuration. The module uses a fully metal-sealed enclosure with an IP20 protection rating, and the internal circuit adopts a three-level EMC filtering design, complying with electromagnetic compatibility standards such as IEC 61000-4-2/3/5. It can resist the strong electromagnetic interference environment of power plants, with a Mean Time Between Failures (MTBF) of ≥500,000 hours.

Multi-Dimensional System Collaboration and ExpansionIt is equipped with rich redundant communication interfaces, including 2 standard 1000Mbps redundant Ethernet ports (supporting EtherNet/IP and Modbus TCP protocols), 2 GE-specific Genius redundant buses, and 1 Profibus-DP interface. It can achieve high-speed data interaction with I/O modules, speed regulation modules, protection modules, HMI (Human-Machine Interface), and SCADA systems, with a data transmission delay of ≤3ms. It supports the "master-slave" module cascading mode; a single master control module can cascade 32 extended I/O modules, and realize inter-module data sharing through the Genius bus with a sharing cycle of ≤0.5ms, meeting the centralized control needs of large-scale units with multiple measurement points and multiple actuators. It has flexible system expansion capabilities, supporting online addition of new functional modules (e.g., denitrification control modules, waste heat utilization control modules) without interrupting the operation of the main control logic, adapting to the unit upgrade and transformation needs.

Full-Link Intelligent Diagnosis and Safety ProtectionA three-level diagnostic system ("module-level - link-level - system-level") is built, with a diagnostic coverage rate of 99.95%. Module-level diagnosis monitors the operating status of the dual cores, power supply voltage, health status of storage units, and interface circuit parameters in real time, performing self-inspection every 0.5ms and triggering local sound and light alarms immediately in case of abnormalities. Link-level diagnosis monitors the connection status with I/O modules and actuators through a communication verification mechanism; in case of communication interruption or data packet loss, it automatically switches to the redundant link and records fault information. System-level diagnosis verifies the consistency between control commands and actual operating parameters through closed-loop feedback from sensors and actuators; for example, when the speed regulation deviation exceeds the threshold, it triggers an early warning and automatically optimizes control parameters. Diagnostic information can be viewed locally through the LCD display and LED indicators, and can also be uploaded to the operation and maintenance platform, supporting the storage and traceability of 2000 fault logs, with each log accompanied by a fault location guide and handling suggestions. It has SIL 3-level safety protection function; in emergency situations (e.g., overspeed, overpressure), it can directly trigger independent trip output with a response time of ≤1ms to ensure unit safety.

Convenient Configuration and Operation & Maintenance ManagementIt supports full-process configuration through GE ControlST V7.0 and above configuration software. The software provides a graphical programming interface, allowing intuitive dragging of function blocks to build control logic, and has a built-in steam turbine control template library (e.g., standard control logic for 300MW and 600MW units) to shorten the configuration cycle. It has online debugging and parameter modification functions, supporting adjustment of key parameters such as PID parameters and alarm thresholds without interrupting the operation of the control logic, and real-time monitoring of the control effect after parameter modification. It supports online firmware upgrade; program updates can be completed through redundant Ethernet, and during the upgrade process, it automatically switches to the standby core for operation to ensure uninterrupted control. It is equipped with a remote operation and maintenance interface, supporting remote fault diagnosis, parameter optimization, and program upgrade through an encrypted network, reducing on-site operation and maintenance costs.

Wide-Range Environmental Adaptability and Flexible InstallationIt has excellent environmental adaptability, with an operating temperature range of -10℃~65℃, a storage temperature range of -40℃~85℃, and a relative humidity of 5%~95% (no condensation), adapting to power plant environments in different regions such as high altitude and high humidity. It adopts 35mm standard rail mounting, with dimensions of 240×180×85mm, featuring a compact structure. A spacing of ≥8mm between adjacent modules can meet heat dissipation requirements, adapting to the installation layout of mainstream control cabinets. It supports both vertical and horizontal installation methods, with an installation torque of 1.5N·m to ensure stable operation of the module in a vibrating environment. The front panel is equipped with a 2.4-inch LCD display and 8 status indicator lights, which can display the module's operating status, key control parameters, and fault codes in real time, facilitating on-site operation and maintenance personnel to quickly troubleshoot problems.

As the core control module of the steam turbine control system, the working principle of GE IS200VCMIH2CAA revolves around five core links: "redundant power supply - signal acquisition - logic calculation - command output - diagnostic feedback". Through dual-core redundant collaboration and a full-process closed-loop control mechanism, it achieves precise regulation and safety assurance of the steam turbine's operating status. The specific process is as follows:

Redundant Power Supply and Power Management LinkTwo independent DC 24V power supplies are connected to the module through redundant power supply interfaces. First, they pass through an EMC filtering module and a surge suppression circuit to filter out high-frequency interference and instantaneous surge signals in the power grid, ensuring stable input power. Then, they enter the dual-channel intelligent power management unit, which is equipped with high-precision voltage and current sensors to monitor the operating parameters of the two power supplies in real time and upload them to the dual-core controller. The controller determines the main and standby power supplies based on parameters such as power supply voltage stability (fluctuation ≤±5%) and load rate (≤70%). By default, the power supply with better parameters is selected as the main power supply, and the other is in a hot standby state, with electrical isolation achieved through an isolation diode. When the main power supply voltage exceeds the range of 20.4-27.6V or the load rate is ≥95%, the power switching circuit quickly switches to the standby power supply within 2ms. During the switching process, a super capacitor (with continuous power supply ≥200ms) maintains the operation of the core circuit to ensure uninterrupted power supply. The stabilized power supply is converted by the DC-DC conversion unit into precise voltages such as 3.3V (for the processor core), 5V (for the interface circuit), and 12V (for the drive circuit), which are supplied to each functional unit after LC filtering. The output ripple is ≤3mV to ensure stable circuit operation.

Multi-Source Signal Acquisition and Preprocessing LinkThe module establishes a high-speed data link with cascaded I/O modules (e.g., IS200TBCIS2CCD) through the Genius bus to collect the steam turbine's operating parameters in real time: analog signals such as speed, vibration, and shaft displacement are converted into digital signals by the I/O modules and then uploaded, with the sampling frequency synchronized with the I/O modules (100Hz-1kHz); digital signals such as main steam valve status, trip signals, and oil pump operating status are uploaded in the form of switch states, with a response time of ≤1ms. At the same time, the module receives control commands (e.g., target load, startup command) issued by the upper-level system through the Ethernet interface. The collected signals first enter the data preprocessing unit, where data validity verification (e.g., whether the analog quantity exceeds the range, whether the digital quantity has jitter), scaling conversion (converting digital signals into actual physical quantities), and digital filtering (eliminating high-frequency noise) are completed. The valid preprocessed data is temporarily stored in the dual-port RAM for reading by the dual-core controller.

Core Control Logic Calculation LinkThe dual-core controller (DSP+ARM) synchronously reads valid data from the dual-port RAM and performs calculations according to the preset control logic: the DSP core focuses on the execution of real-time control algorithms, such as speed PID regulation, load coordination control, and steam pressure/temperature closed-loop control, with a calculation cycle as low as 0.1ms to ensure control real-time performance; the ARM core is responsible for logic judgment and collaborative scheduling, such as switching control strategies according to the steam turbine startup phases (run-up, speed increase, grid connection) and optimizing control parameters based on the unit's operating status (e.g., reducing load when vibration exceeds the standard). During the calculation process, the dual cores perform real-time cross-validation of the calculation results. If the deviation is ≤0.05%, the result is determined to be valid and a control command is generated; if the deviation exceeds the threshold, a self-inspection program is immediately activated to locate the faulty core, isolate the faulty unit, and the standby core takes over the calculation, while triggering a redundant fault alarm. For emergency fault signals (e.g., overspeed of 110% rated speed), the system activates the hard-wired independent trip logic, directly outputting a trip command without complex calculations, with a response time of ≤1ms.

Control Command Output and Execution LinkThe valid control commands are classified and processed by the command distribution unit and then output through the corresponding interfaces: for analog actuators such as speed control valves and regulating valves, the commands are converted into 4-20mA standard signals through DA conversion and output to the actuators through the I/O module, with an output accuracy of ±0.2% FS; for digital actuators such as oil pumps, fans, and main steam valves, the commands are amplified by the drive circuit to control the action of the relay. The relay contact capacity reaches 250V AC/30V DC, 2A, with an action response time of ≤2ms. The output link is equipped with a feedback monitoring circuit, which collects the actual action status of the actuator (e.g., speed control valve opening feedback, main steam valve position feedback) in real time and uploads it to the controller to form closed-loop control. If it is detected that the deviation between the control command and the feedback status exceeds the threshold (e.g., the command opening is 50%, and the actual opening deviation is ≥5%), the controller automatically adjusts the output command or triggers a fault alarm.

Full-Link Diagnosis and Feedback LinkThe module performs three-level diagnosis in real time: ① Module-level diagnosis: self-inspects the operating status of the dual cores, power supply voltage, and health status of the storage unit every 0.5ms; if the processor frequency is abnormal, the power supply voltage fluctuation exceeds the range, or the storage unit has read/write errors, it immediately triggers a local alarm; ② Link-level diagnosis: monitors the communication status with I/O modules and upper-level systems through communication check codes; if the packet loss rate is ≥1% or communication is interrupted, it automatically switches to the redundant link and records link fault information; ③ System-level diagnosis: compares the consistency between control commands and execution feedback, and judges the control effect based on the steam turbine's operating parameters (e.g., speed, vibration); if the regulation deviation continuously exceeds the threshold (e.g., speed fluctuation ≥±0.1% rated speed), it automatically optimizes the PID parameters and triggers an early warning.

![]()