Description

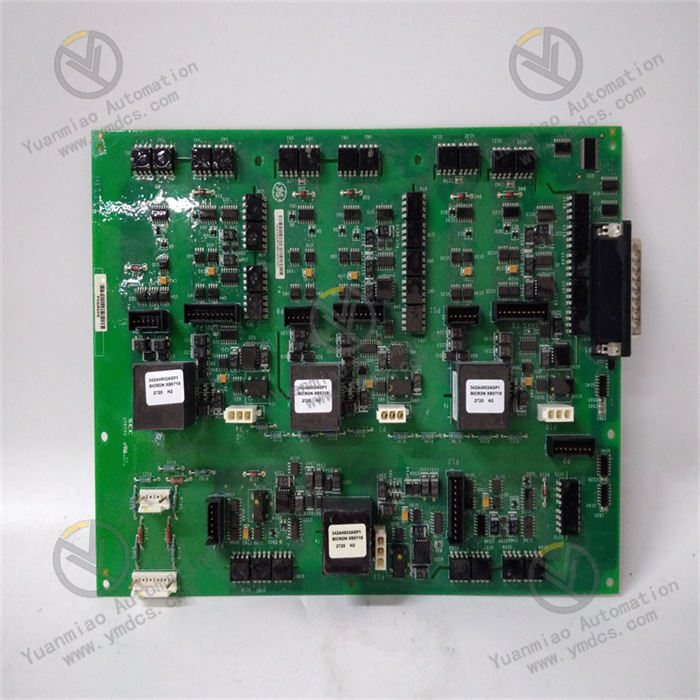

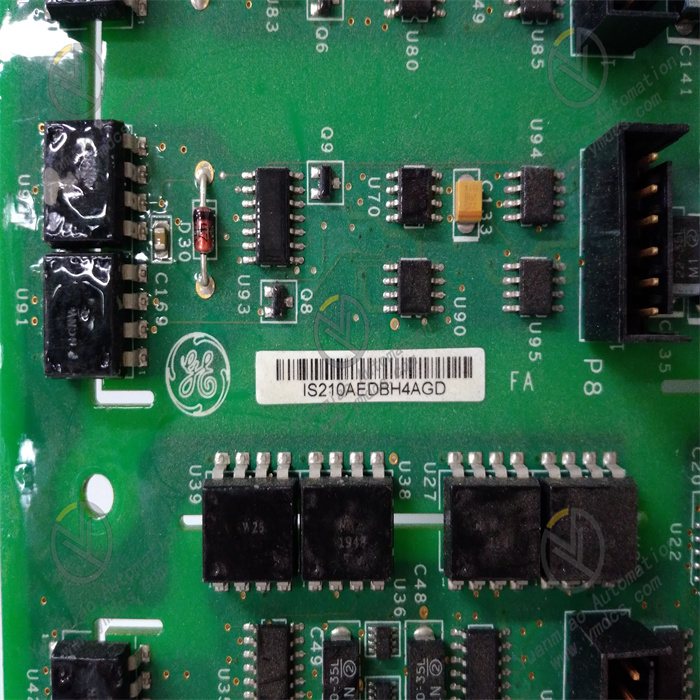

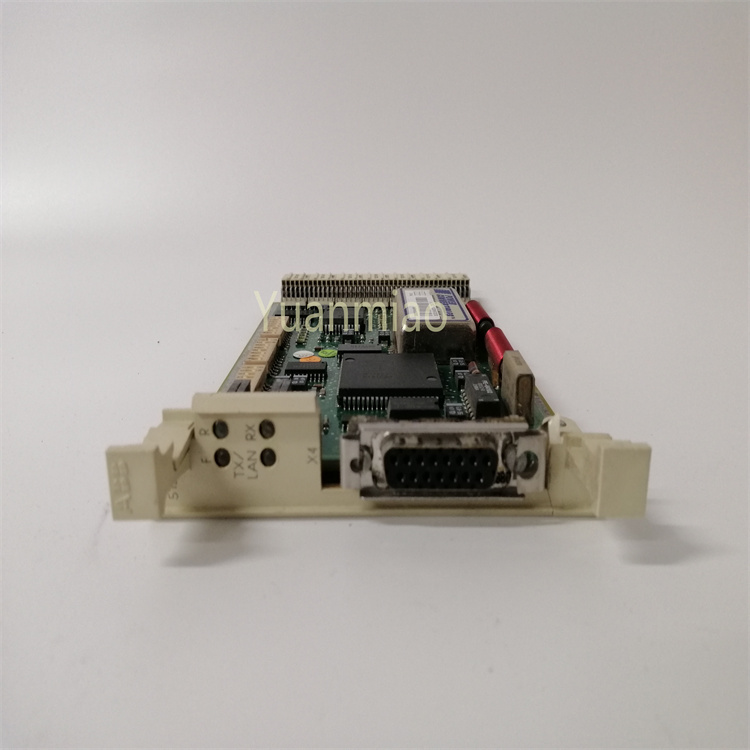

GE IS210AEDBH4AGD

I. Overview

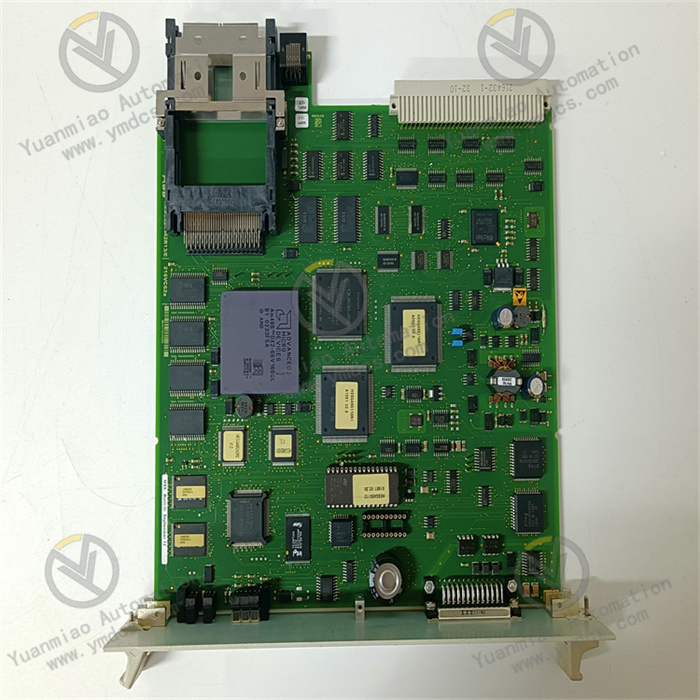

The GE IS210AEDBH4AGD is a high-performance digital input terminal board, specifically designed for the Mark VIe and Mark VIeS series turbine and generator control systems. Within the overall system architecture, it plays a crucial role as a "pioneer in signal acquisition," responsible for accurately monitoring the on/off signals of various on-site equipment. It is one of the core components ensuring the stable and efficient operation of turbine and generator control systems.

II. Functions and Applications

(I) Signal Acquisition and Transmission

High-Density Interface Function

As a high-density interface for digital inputs, the IS210AEDBH4AGD boasts strong signal acceptance capability. It can simultaneously receive signals from various on-site devices such as limit switches, proximity sensors, pressure switches, and relay contacts. For instance, in the gas turbine control system of a large power plant, limit switches installed at different locations are used to monitor the opening and closing status of valves, and the signals generated by these switches are continuously transmitted to the IS210AEDBH4AGD. Its high-channel design (typically 24 or more digital input channels) acts like an efficient "traffic hub," ensuring the orderly convergence of numerous signals.

Signal Conditioning and Routing

Upon receiving signals, the terminal board quickly conditions them. It converts signals of different voltage levels and characteristics from on-site equipment into a standard signal format suitable for system transmission and processing. Subsequently, these conditioned signals are accurately routed to the main controller (e.g., IS200 series) via the backplane. In the safety instrumented system of a petrochemical plant, after a pressure switch detects an abnormal pressure signal, the IS210AEDBH4AGD not only receives it quickly but also completes signal conditioning in an extremely short time and transmits it to the main controller accurately, enabling the system to take timely response measures.

(II) Adaptability to Harsh Environments

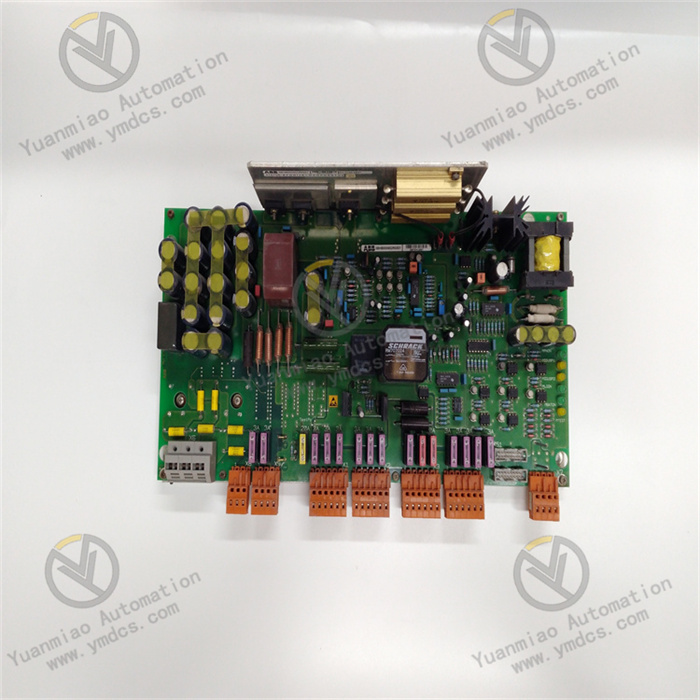

Robust Design Ensures Reliability

In complex environments such as power plants and industrial facilities, there are strong electromagnetic interference, significant temperature and humidity fluctuations, and a large amount of dust. The IS210AEDBH4AGD adopts a robust design, and its shell material and internal circuit layout are fully designed to resist harsh environments. Its shell has excellent electromagnetic shielding performance, which can effectively block the impact of external electromagnetic interference on internal circuits, ensuring the accuracy and stability of data acquisition. Even in high-temperature and high-humidity chemical workshops, it can operate stably, guaranteeing reliable data acquisition by the control system.

III. Technical Specifications

(I) Basic Parameters

Product Type

It is clearly defined as a digital input terminal board, focusing on the access and processing of digital signals. In industrial automation control systems, it provides accurate digital input data for subsequent control decisions.

Manufacturer

Manufactured by the industry-renowned General Electric (GE). GE has profound technical accumulation and rich practical experience in the field of industrial control, providing strong guarantees for product quality and performance.

Part Number

IS210AEDBH4AGD. This unique number facilitates users in accurately identifying and distinguishing the product during equipment selection, procurement, and maintenance processes.

(II) System Compatibility

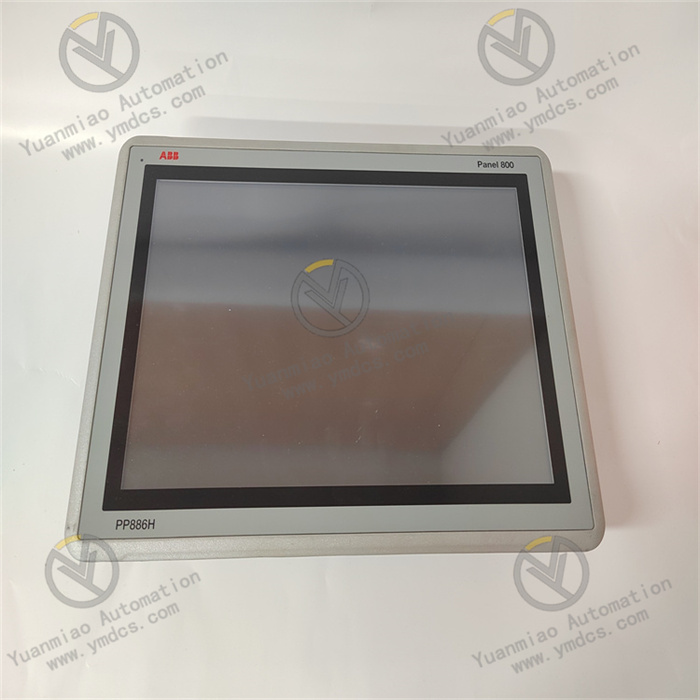

Compatibility with Mark VIe and Mark VIeS Systems

It is perfectly compatible with the Mark VIe and Mark VIeS series turbine and generator control systems, enabling seamless integration into the architecture of this series of systems and collaborative operation with other components to give full play to the performance advantages of the entire control system. Whether for the construction of new systems or the upgrading of old systems, it can easily realize direct replacement of existing Mark VIe devices, ensuring the continuity and stability of the system.

(III) Input Characteristics

Input Type

Supports digital (binary) signal input. This type of signal is widely used in industrial control, representing the on/off and connection/disconnection status of equipment through simple "0" and "1" states, facilitating logical judgment and processing by the system.

Number of Channels

Equipped with a high number of channels, with a common configuration of 24 or more digital input channels, which can meet the demand for signal acquisition from a large number of on-site equipment in large-scale industrial control systems. In large-scale oil and gas extraction projects, the status signals of numerous equipment such as pumps and compressors can be simultaneously connected to the system through multiple channels of the IS210AEDBH4AGD.

Input Voltage

It has good voltage adaptability, usually supporting multiple input voltages such as 24 V DC or 125 V DC/AC. It can adapt to the output voltage specifications of different on-site equipment, reducing the trouble of adding additional conversion equipment due to voltage mismatch.

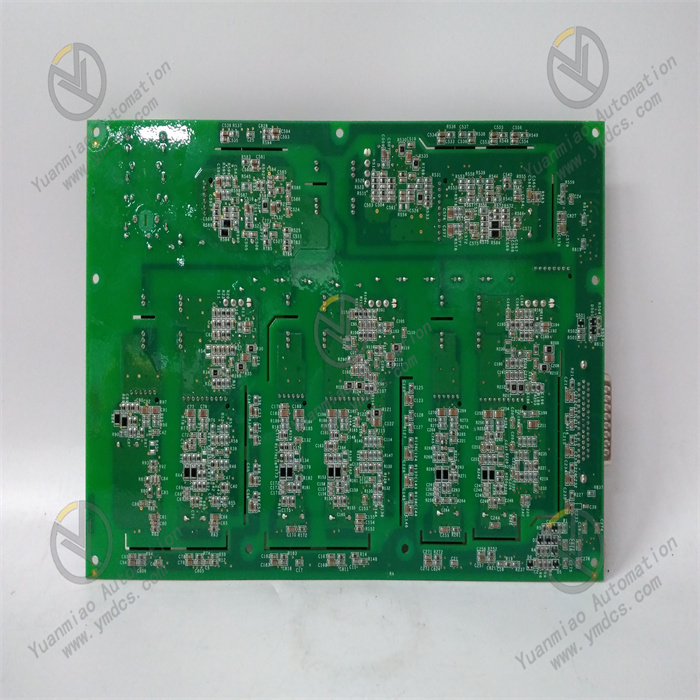

(IV) Isolation Protection

Isolation Function

Provides reliable isolation protection, establishing a safety barrier between on-site equipment and control electronic equipment. When transient voltage occurs on-site or there is strong noise interference, this isolation protection mechanism can effectively prevent these interference signals from entering the control electronic equipment, protect the control circuit from damage, and ensure the stable operation of the control system. For example, in an industrial environment where motors start and stop frequently, the instantaneous high-voltage spikes generated when the motor starts will not affect the control electronic equipment.

(V) Installation Method

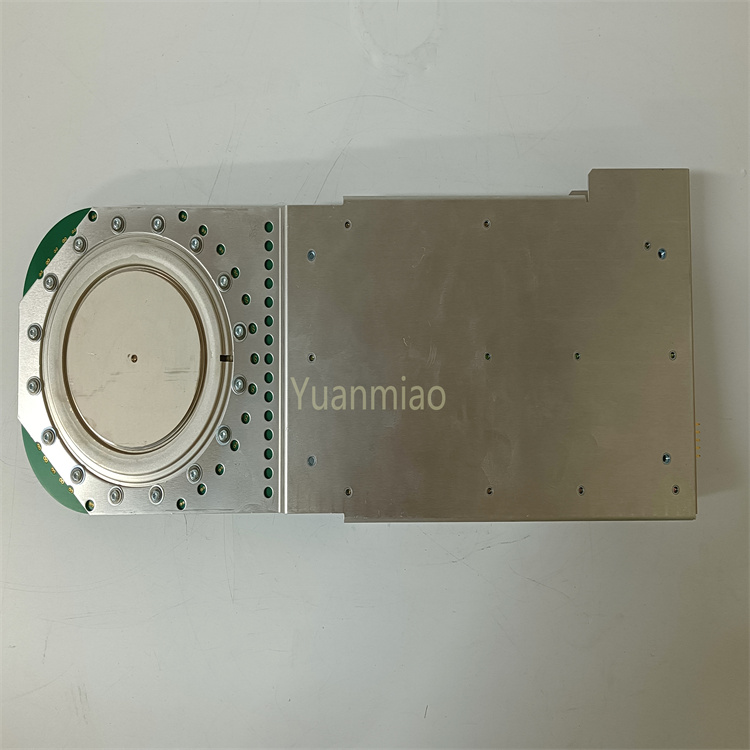

Rack or Panel Mount Design

Adopts a rack or panel mounting method and is equipped with specific I/O components, facilitating installation and fixation in locations such as industrial control cabinets and equipment racks. This standardized installation design makes the installation, commissioning, and maintenance of the equipment more convenient and efficient, meeting the requirements of industrial automation systems for the universality and convenience of equipment installation.

IV. Application Fields

(I) Power Generation Industry

Gas Turbine and Steam Turbine Control Systems

In the power generation field, especially in gas turbine and steam turbine control systems, the IS210AEDBH4AGD plays a vital role. It monitors the opening and closing status of valves in real time to ensure the precise control of steam or gas flow; monitors the operating status of pumps to ensure the normal operation of cooling, lubrication, and other systems; monitors the on/off status of circuit breakers to detect electrical faults in a timely manner; at the same time, it also pays close attention to the status of emergency shutdown devices. Once an emergency shutdown signal is triggered, it can quickly transmit the signal to the control system to ensure the safe shutdown of the unit. For example, in the steam turbine control system of a large thermal power plant, the IS210AEDBH4AGD collects signals from hundreds of on-site equipment in real time, providing a solid guarantee for the stable operation and efficient power generation of the unit.

(II) Oil and Gas Industry

Compressor Station and Pump Control Systems

In the process of oil and gas extraction and transportation, compressor stations are used to increase gas pressure, and pump control systems are used to transport liquids. In such systems, the IS210AEDBH4AGD monitors the operating status of compressors and pumps in real time, including pressure switch signals (reflecting whether the pressure is normal) and limit switch signals (monitoring valve positions). By monitoring these key switch states, it ensures the stable operation of compressors and pumps and avoids production interruptions caused by equipment failures. For example, in the compressor station of a long-distance natural gas transmission pipeline, the IS210AEDBH4AGD always monitors the operation of equipment to ensure the stable transmission of natural gas.

Safety Instrumented Systems

Safety instrumented systems are an important line of defense for safe production in the oil and gas industry. As a key component of these systems, the IS210AEDBH4AGD is responsible for collecting various safety-related switch signals, such as alarm signals from flammable gas detectors and status signals from emergency shut-off valves. In case of abnormal situations, it can quickly transmit the signals to the core controller of the safety instrumented system, triggering corresponding safety protection actions such as closing valves and activating alarm devices, effectively preventing the occurrence and expansion of accidents.

(III) Petrochemical Industry

Refinery and Chemical Plant Control Systems

In refineries and chemical plants in the petrochemical industry, the production process is complex, involving numerous chemical reactions and physical processes. The IS210AEDBH4AGD is integrated into these control systems to monitor and manage process safety interlock devices. For example, in the control system of a chemical reactor, it monitors the switch signals of sensors for temperature, pressure, liquid level, etc., as well as the status signals of related valves and pumps. When a parameter exceeds the safe range or equipment malfunctions, it triggers the interlock device in a timely manner and takes corresponding safety measures, such as stopping the reaction and discharging materials, to ensure the safe and stable production process.

(IV) Old System Upgrading

System Continuity Guarantee

For existing Mark VIe devices, with the passage of time and technological development, upgrades and transformations may be required to improve performance or meet new production needs. The IS210AEDBH4AGD can directly replace the corresponding components in existing devices, ensuring system continuity during the upgrade process and reducing downtime caused by equipment replacement. At the same time, it is compatible with new control technologies and equipment, extending the service life of the entire system and saving equipment update costs for enterprises. For example, an enterprise upgraded its old gas turbine control system by replacing the original digital input terminal board with the IS210AEDBH4AGD, which not only improved the signal acquisition accuracy and reliability of the system but also enabled the system to adapt to new control strategies and improved power generation efficiency.