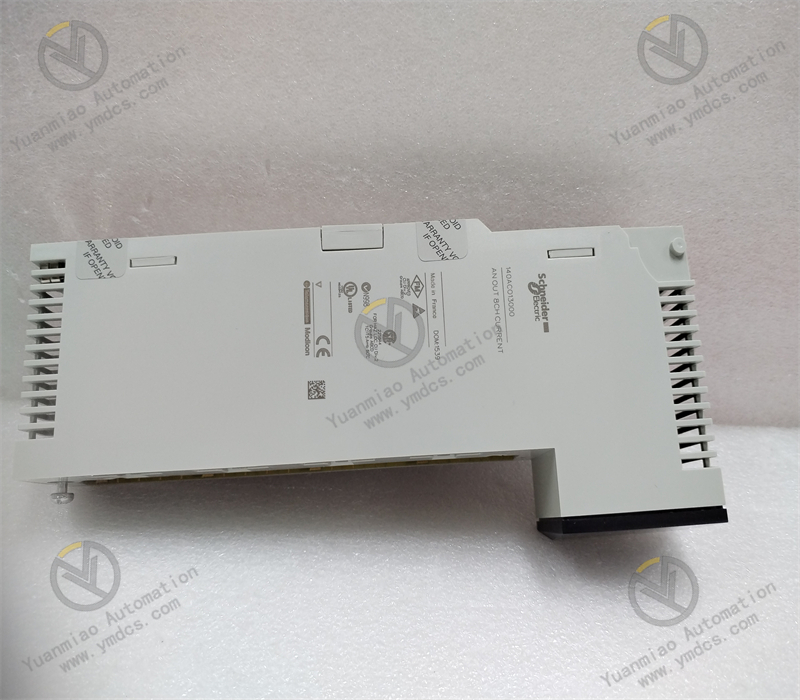

Description

Functional Features Analog Output: This module is capable of outputting various standard analog signals, such as 4 - 20mA, 0 - 10V, etc. It can precisely control connected devices, such as control valves, frequency converters, etc. It adjusts the output signals according to the instructions of the control system, thus achieving precise control of various parameters (such as flow rate, pressure, temperature, etc.) in the industrial process. High-precision Output: It has a high output precision and can meet the strict requirements for analog control precision in industrial production. Generally speaking, its resolution can reach 12 bits or 16 bits, which means it can provide very delicate output changes, ensuring the stability and accuracy of device operation. Number of Channels and Independent Control: It usually has multiple analog output channels (for the specific number, please refer to the product manual). Each channel can be set and controlled independently. This enables users to flexibly configure parameters such as the output range and linearity of each channel according to actual needs to adapt to different industrial application scenarios. Communication Function: As a part of the Modicon Quantum series, this module can communicate with other modules (such as CPU modules, input modules, etc.) through the Quantum bus to achieve fast data transmission and exchange. It supports Schneider Electric's communication protocol and can be seamlessly integrated with the entire control system, facilitating users to program, debug and monitor the system. Fault Diagnosis and Protection: It has a certain fault diagnosis capability and can monitor its own working status in real time. When abnormal situations (such as output short circuit, overload, etc.) are detected, the module can promptly send out alarm signals and take corresponding protective measures, such as automatically cutting off the output or maintaining the output value within a safe range, to prevent device damage and production accidents.

Technical Parameters

Power Requirements: It usually requires a stable DC power supply. The common power voltage specification is 24V DC, and the power fluctuation range is within a certain allowable value to ensure the normal operation of the module.

Output Range: It supports a variety of analog output ranges, such as 4 - 20mA, 0 - 10V, 0 - 20mA, etc. Users can select and configure according to actual needs.

Output Precision: The resolution is generally 12 bits or 16 bits, and the output precision can reach ±0.5% of the full scale (for specific precision parameters, please refer to the product manual), which can provide precise analog output.

Response Time: It has a fast response speed to control commands and can generally complete the output update within dozens of milliseconds to meet the requirements for real-time control in industrial production.

Operating Temperature Range: To adapt to the industrial environment, the operating temperature range of this module is generally between 0°C and 55°C. In some special models, it may have a wider operating temperature range to meet the needs of different industrial sites.

Protection Level: It usually has a certain protection level, such as IP20, which can prevent dust and small solid foreign objects from entering the inside of the module and provide a certain protective effect on the module.

Technical Parameters

Power Requirements: It usually requires a stable DC power supply. The common power voltage specification is 24V DC, and the power fluctuation range is within a certain allowable value to ensure the normal operation of the module.

Output Range: It supports a variety of analog output ranges, such as 4 - 20mA, 0 - 10V, 0 - 20mA, etc. Users can select and configure according to actual needs.

Output Precision: The resolution is generally 12 bits or 16 bits, and the output precision can reach ±0.5% of the full scale (for specific precision parameters, please refer to the product manual), which can provide precise analog output.

Response Time: It has a fast response speed to control commands and can generally complete the output update within dozens of milliseconds to meet the requirements for real-time control in industrial production.

Operating Temperature Range: To adapt to the industrial environment, the operating temperature range of this module is generally between 0°C and 55°C. In some special models, it may have a wider operating temperature range to meet the needs of different industrial sites.

Protection Level: It usually has a certain protection level, such as IP20, which can prevent dust and small solid foreign objects from entering the inside of the module and provide a certain protective effect on the module.

Application Areas Process Industry: In the process control of industries such as chemical, petroleum, power, and metallurgy, it is used to precisely control various process parameters. For example, in chemical production, it controls the temperature, pressure, and flow rate of the reactor; in the power system, it regulates the output voltage and current of the generator, etc. Manufacturing Automation: In the automated production lines of industries such as automobile manufacturing and electronics manufacturing, it is used to control the operating parameters of robots, machine tools, conveying equipment, etc. For example, it controls the movement speed and position of the robotic arm to achieve precise processing and assembly operations. Smart Building: In the smart building system, it is used to control the operation of air conditioning systems, lighting systems, elevator systems, etc. For example, it adjusts the cooling or heating output of the air conditioner according to the indoor temperature and humidity to achieve optimized energy management. Energy Management: In the fields of energy production and distribution, it is used to monitor and control the operating status and output parameters of energy equipment. For example, in a wind farm, it controls the output power of the wind turbine; in a solar power station, it regulates the output voltage and current of the photovoltaic cells, etc.