Description

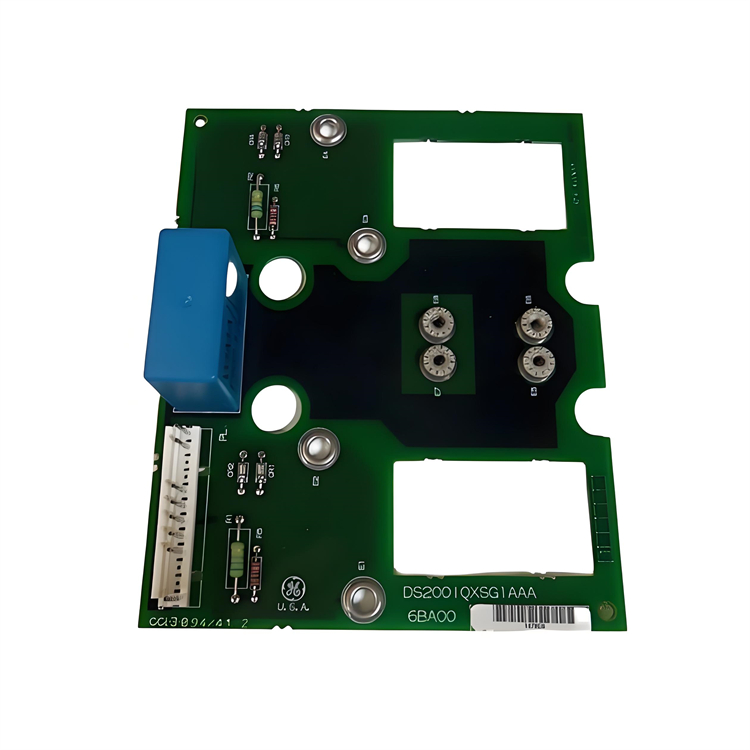

GE IS220PSVOH1A

GE IS220PSVOH1A is a servo control module mainly applied in the Mark VI and Mark VIe systems, which play a crucial role in the control field of steam and gas turbines. Within the industrial automation system, this module undertakes the key task of establishing electrical connections between one or two I/O Ethernet networks and the tsvo servo terminal board. Meanwhile, it achieves precise control over two servo valve position loops by means of the wsvo servo driver module, ensuring the stable and efficient operation of industrial turbine equipment.

The IS220PSVOH1A module is responsible for the servo control of gas turbines. When there is a significant fluctuation in the power grid load, the module can respond within milliseconds, accurately adjusting the opening degree of the servo valve to ensure the stable adjustment of the gas turbine's output power. This avoids equipment failures and power grid impacts caused by sudden power changes, effectively improving the reliability and stability of the power supply in power stations. In large-scale steam-driven compressor systems in the chemical industry, the module ensures the stable speed of the compressor through the precise control of the steam turbine servo system. This guarantees the stable delivery of gas in the chemical process flow, prevents product quality issues and production interruptions caused by speed fluctuations, and reduces the economic losses of enterprises due to abnormal production by over one million yuan annually.

The IS220PSVOH1A adopts a compact and robust design concept. The front panel of the module is equipped with multiple LED indicators, such as the ENET 1/ENET 2 indicators for displaying the Ethernet network status, power indicator, ATTN indicator, and ENA 1/2 indicators. Maintenance personnel can intuitively grasp the operating status of the module through these indicators. Internally, it is equipped with a processor board integrated with an input power connector to provide stable power supply for the module; a local power supply is also provided to ensure power supply in complex industrial environments. Additionally, an on-board temperature sensor is installed to monitor the internal temperature of the module in real-time and prevent performance impacts due to overheating. It also has flash memory and random access memory (RAM) for storing key data and operating programs. The overall size of the module is compact, facilitating installation in various industrial control cabinets and adapting to a variety of industrial installation environments. It can be easily adapted to both on-site control cabinets with limited space and centralized control centers with strict requirements for module layout.

Relying on advanced algorithms and hardware design, the IS220PSVOH1A achieves high-precision control of servo valves:

- Precise Dual-Loop Regulation: It controls two servo valve position loops simultaneously. In the control of the steam turbine for the blast furnace blower in a large iron and steel plant, it can independently and precisely adjust the inlet valve and exhaust valve respectively, ensuring that the rotational speed of the steam turbine is stabilized within the range of ±1r/min of the set value. This guarantees the stable blast pressure of the blast furnace and meets the strict air volume requirements of iron and steel smelting.

- High-Resolution Processing of LVDT Signals: It performs high-resolution processing on 8 channels of LVDT input signals, with a resolution of up to 0.001mm. It can accurately sense the position change of the servo valve core and adjust the control signal in a timely manner. In the servo control of chemical centrifugal compressors, it can effectively avoid gas leakage and reduced compression efficiency caused by the deviation of the valve core position.

- Real-Time Monitoring of Pulse Rate Inputs: Through 2 pulse rate inputs, it monitors the pulse signals of external equipment in real-time. In the wind turbine control system of a wind farm, it can quickly respond to the pulse signals of wind speed changes, adjust the wind turbine pitch angle in a timely manner, and improve the wind energy capture efficiency and power generation stability.

The module has a built-in intelligent diagnosis system to ensure the continuity of industrial production:

- Comprehensive Fault Diagnosis: It conducts all-round fault diagnosis from hardware-level faults (such as power supply, processor, and network communication) to control-level faults (such as servo loops). In the gas turbine control system of a thermal power plant, when the module detects an open-circuit fault in the feedback line of a certain servo valve, it triggers a fault alarm within 10ms, uploads the fault information to the control system, and automatically switches to the backup control channel to maintain the normal operation of the gas turbine.

- Automatic Reconfiguration and Manual Fine-Tuning: When the module is replaced, the automatic reconfiguration function can quickly restore the system operation. In power emergency repair scenarios, it can shorten the downtime caused by module replacement to less than 10 minutes; if personalized adjustment is required, the manual reconfiguration function can meet the fine setting needs under complex working conditions. For example, in the control of special process turbines in petrochemical plants, the control parameters can be fine-tuned according to the process requirements.

Aiming at complex and harsh industrial environments, the IS220PSVOH1A has been designed specifically:

- Stable Operation at Wide Temperatures: Within the operating temperature range of 0℃~60℃, it uses industrial-grade components, such as high-temperature-resistant capacitors and chips with excellent low-temperature performance. It can operate normally in the control boxes of wind turbines outdoors in northern winters (-10℃) and in the central control rooms of cement plants in high temperatures in southern summers (55℃), ensuring uninterrupted equipment operation.

- Moisture and Corrosion Resistance: The conformal coating technology and sealing design enable the module to operate continuously for 5 years in chemical workshops with high humidity and corrosive gases without faults such as PCB board corrosion and short circuits, reducing maintenance costs.

- Strong Electromagnetic Protection: By optimizing the circuit layout and adding shielding layers, it effectively resists strong electromagnetic interference in industrial sites. In the steel rolling workshops of iron and steel plants, where there are a large number of large motors and frequency converters around, the data collected and transmitted by the module has no packet loss or bit error, ensuring the accuracy of control signals.

From installation to operation and maintenance, the IS220PSVOH1A fully considers user needs:

- Multiple Installation Methods: Two installation methods (35mm guide rail installation and screw fixing) facilitate flexible installation in different control cabinet structures. In the integration of automation control systems in new factories, the module can be quickly installed according to the control cabinet design.

- Intuitive LED Indicators: The rich LED indicators on the front panel allow maintenance personnel to judge the operating status of the module from a distance (e.g., a steady green light indicates normal operation, and a flashing red light indicates a fault). In the centralized monitoring areas of large factories, faulty modules can be quickly located, improving maintenance efficiency.

- Remote Configuration and Diagnosis: It supports remote configuration and diagnosis via Ethernet. In cross-regional industrial enterprises, technical personnel at the headquarters can conduct real-time parameter adjustment and fault troubleshooting for the IS220PSVOH1A modules in factories in different locations, saving labor and time costs.

![]()