Description

SPECIFICATIONS

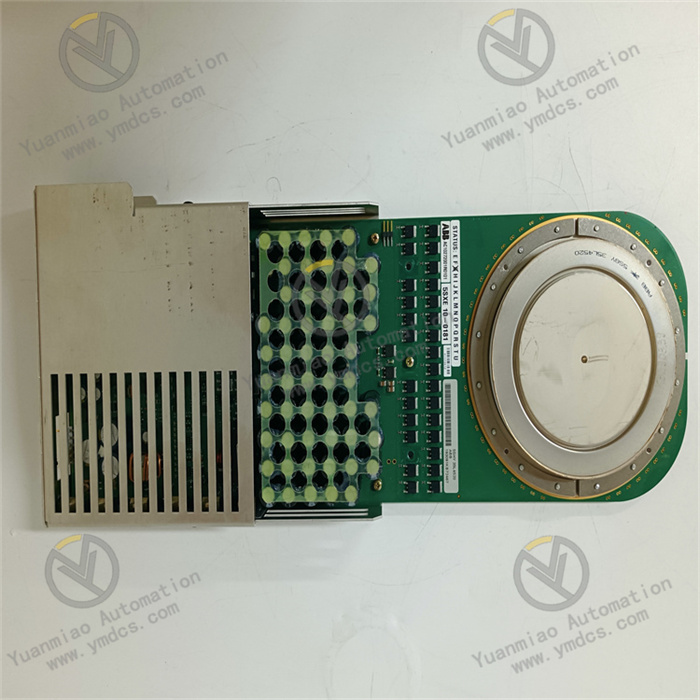

Part No.: IS220PPRFH1B

Manufacturer: General Electric

Product Type: PROFIBUS Master Gateway I/O Module

Country of Manufacture: United States (USA)

Series: Mark VIe

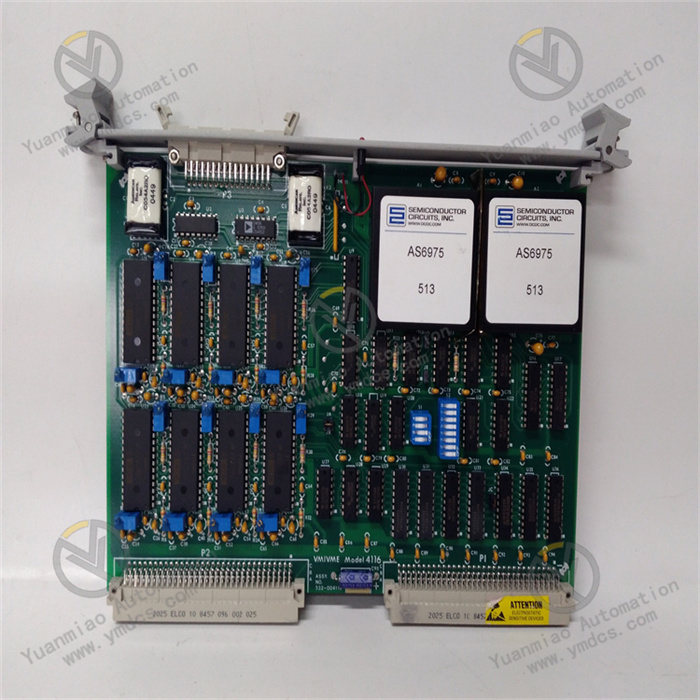

IS220PPRFH1B is a PROFIBUS Master Gateway I/O Module developed by GE under Mark VIe series. It is a PROFIBUS DPV0, Class 1 master that maps Mark VIe controllers on the I/O Ethernet to I/O from PROFIBUS slave devices. The module includes a processor board that is shared by all Mark VIe distributed I/O modules and an acquisition carrier board that is equipped with a Hilscher GmbH-provided COM-C PROFIBUS communication module.

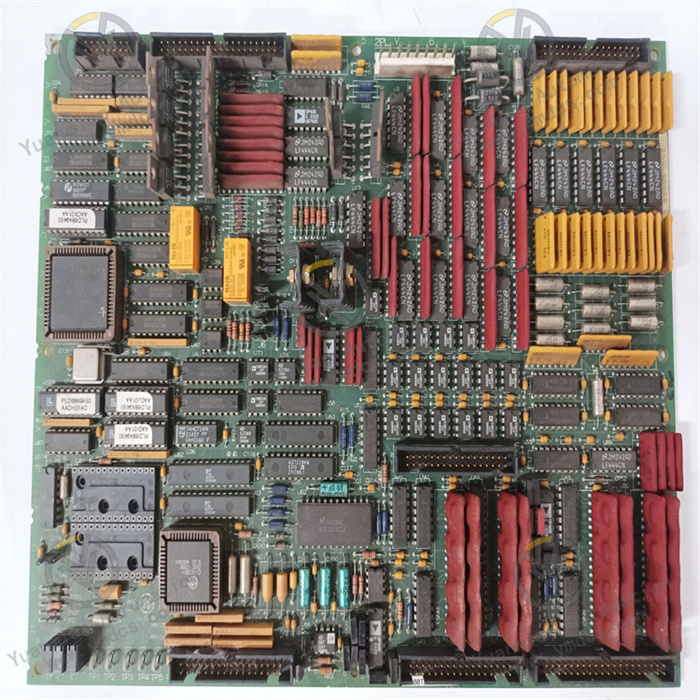

Working Principle This module includes a processor board shared by all Mark VIe distributed I/O modules and an acquisition carrier board equipped with a COM-C PROFIBUS communication module provided by Hilscher GmbH. The COM-C module provides a PROFIBUS RS-485 interface through a DE-9 D-sub socket connector, acting as a PROFIBUS DP master station. It supports up to 125 slave stations, and can map the Mark VIe controller on the I/O Ethernet to the I/O of the PROFIBUS slave station device, enabling data communication and signal exchange between them. When the input power is applied, the soft-start circuit raises the available voltage on the processor board, turns off the processor reset in sequence and turns on the local power supply. After completing the self-check routine, the processor loads the application code specific to the I/O package or module type from the flash memory, and reads the board ID information to verify whether the application code, acquisition board and terminal board are correctly matched.

Functional Features Powerful communication function: It is a PROFIBUS DPV0, Class 1 master station, supporting PROFIBUS DP V0 and V1 protocols. It can communicate with numerous PROFIBUS slave station devices, with a transmission rate ranging from 9.6KBaud to 12MBaud. Rich redundancy options: It supports various redundancy configurations, such as a single I/O Ethernet connection for a single I/O package, a single I/O package with two I/O Ethernet connections, a hot backup Ethernet connection with two ports, etc., improving the reliability of the system. Complete diagnostic function: The LED indicators on the module can provide visual diagnosis, helping users quickly determine the working status of the module, such as standby/active, communication status, system operation status, etc.

Technical Parameters

Electrical parameters: The nominal input voltage is 28V DC, and the maximum input current is 0.18A DC.

Environmental parameters: The rated ambient temperature is from -20°C to +55°C (-4°F to +131°F), and it has ATEX Zone 2, Group IIC certification as well as UL certification (UL E207685).

Communication parameters: As a PROFIBUS DP master station, it supports up to 125 slave stations. Each slave station can handle 255 bytes of input and output. The I/O throughput is semi-binary and semi-analog, with 500 inputs and 500 outputs, and a frame rate of 40ms.

Common Faults and Solutions Communication faults: These may be caused by poor communication line connections, incorrect communication parameter settings, or damage to the module communication interface. It is necessary to check whether the communication line is properly connected, confirm whether the communication parameter settings are consistent with other devices, and contact the manufacturer for repair or replace the module communication interface if it is damaged. Module faults: For situations such as abnormal LED indicators or the module not working properly. These may be due to hardware faults of the module itself, power supply problems, or external interference. First, check whether the power supply of the module is normal, check whether there are strong electromagnetic interference sources around, try to reset or reinitialize the module. If the problem still exists, contact professional maintenance personnel for inspection and repair. Abnormal data transmission: There may be problems such as data loss, errors, or transmission delays. These may be caused by network faults, electromagnetic interference, or incorrect module configuration. Check whether the network connection is stable, eliminate electromagnetic interference factors, check whether the data transmission configuration parameters of the module are correct, and reconfigure them if there are errors.

Application Scenarios Energy field: It is widely used in energy production scenarios such as gas turbines, steam turbines, and wind power generation. It is used to connect the turbine control system with various field sensors, actuators and other devices, achieving real-time monitoring and precise control of the turbine operation status, ensuring the efficient and stable operation of energy production equipment. Industrial automation production line: It can connect various PROFIBUS devices on the production line, such as PLCs, robots, intelligent instruments, etc., to the Modbus TCP or Modbus RTU network, achieving efficient data exchange and collaborative work among different devices, facilitating centralized control and management of the entire production line, and improving production efficiency and product quality. Petroleum and natural gas industry: In the links of oil extraction, refining, and natural gas transportation, it is used to connect various field monitoring devices and control devices, achieving remote monitoring and automated control of the production process, helping to improve production safety and operational efficiency, and promptly detecting and handling potential production faults. Water treatment system: In facilities such as waterworks and sewage treatment plants, it can connect water quality monitoring sensors, water pumps, valves and other devices through the PROFIBUS bus, and then access the Modbus network through this module, achieving automated control and remote monitoring of the water treatment process, ensuring that the water quality meets the standards and the system operates stably.