Description

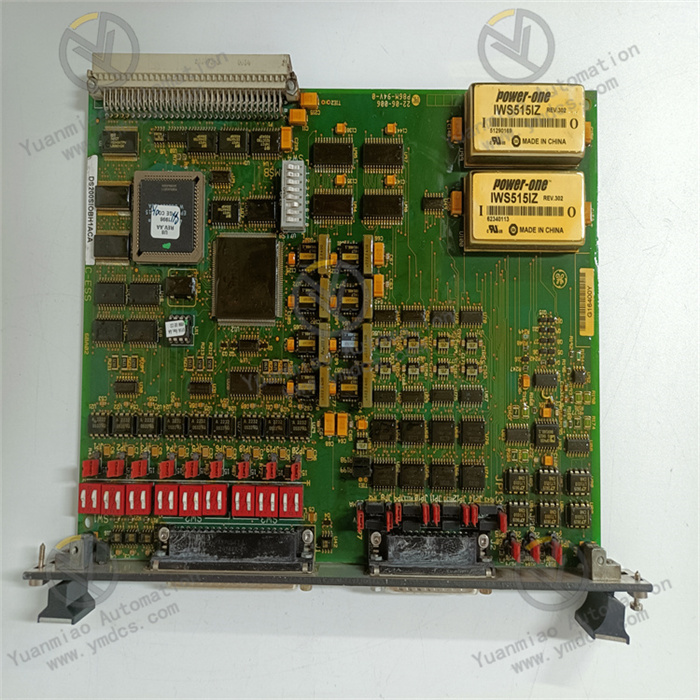

GE IS220PDIOH1B

I. Product Overview

The GE IS220PDIOH1B is a dedicated integrated DI/DO (Digital Input/Digital Output) module for the Mark VIe system. It must be used in conjunction with Mark VIe main controllers (e.g., IS220PPROH1A), high-power actuators (4A solenoid valves, motor contactors), digital sensors (high-temperature resistant limit switches, fault contacts), and the Ionet redundant bus. Its core functions are upgraded and optimized based on the IS220PDIOH1A, including the following specific aspects:

- Upgraded High-Load DO Drive: Supports 16-channel isolated DO (24V DC, with a single-channel continuous output current of 4A and a peak output current of 10A/100ms). Compared with the IS220PDIOH1A (2A), this represents a 100% increase in output current. It can directly drive high-power actuators (e.g., 3kW motor contactors) without the need for additional power amplification modules.

- Enhanced DI Signal Adaptability: The 16-channel isolated DI is compatible with 24V DC dry contacts/PNP/NPN. A new "adjustable high-level threshold" function (configurable via software within the 12V-24V range) is added to adapt to sensors from different brands (e.g., Omron, Schneider) and prevent false signal triggering.

- Reinforced Full-Link Redundancy: On the basis of the dual Ionet bus, a new "dual-power input" design (24V DC A/B channels with independent power supply) is introduced. When a single power channel fails, it switches to the backup power supply within 0.1ms. Key chips (MCU, DO driver) adopt industrial-grade redundant backup, and the Mean Time Between Failures (MTBF) is increased to ≥120,000 hours.

- Wide Operating Condition Adaptability: The operating temperature range is expanded to -30℃~75℃ (compared to -20℃~70℃ for the IS220PDIOH1A). A new anti-vibration design (compliant with IEC 60068-2-6 standard, 10-500Hz, 3g acceleration) is added to adapt to extreme scenarios such as vibrating equipment in metallurgical plants and power plants in cold northern regions.

- Upgraded Intelligent Diagnosis: A built-in temperature sensor (with an accuracy of ±1℃) monitors the internal temperature of the module in real time. When the temperature exceeds the threshold, it automatically reduces the output current (DO current decreases from 4A to 2A). It supports dual diagnosis of DO open circuit/short circuit (response ≤1μs), and the fault location accuracy is improved to the single-channel level.

From the perspective of application value: In the blast furnace fan control system of a metallurgical plant, the IS220PDIOH1B directly drives 4A fan contactors through 16 DO channels (without an amplification module). The DO output delay is ≤80μs, and the fan start-stop error is reduced from ±8ms to ±0.8ms. In a cold northern power plant (-28℃ in winter), the module starts normally at a low temperature of -30℃ and operates continuously for 90 days without faults (the IS220PDIOH1A is prone to shutdown in low-temperature environments). In the rolling mill system of a heavy machinery factory, the module withstands 3g vibration (during rolling mill operation), with a DI signal false trigger rate of 0 and no fluctuation in DO output (traditional modules have 1-2 false operations per month, resulting in losses exceeding 500,000 yuan).

II. Technical Parameters

1. DI/DO Performance Parameters (Key Upgrades Highlighted)

| Parameter Category | Specific Specifications (Digital Input, DI) | Specific Specifications (Digital Output, DO; Upgrades Compared to IS220PDIOH1A) |

|---|---|---|

| Number of Channels | 16-channel isolated DI, with independent isolated power supplies for every 4 channels (consistent with the previous generation) | 16-channel isolated DO, with independent drive circuits for every 2 channels (the previous generation had 4 channels per group, with enhanced driving capability) |

| Signal Type | 24V DC dry contact (adjustable high level ≥12V-24V, low level ≤5V); compatible with PNP/NPN (sourcing/sinking modes) | 24V DC, single-channel continuous output current of 4A (2A for the previous generation), peak output current of 10A/100ms (5A for the previous generation); supports normally open/normally closed logic (configurable via software) |

| Response Time | Hardware response ≤40μs (50μs for the previous generation); ≤80μs after software filtering (with 0.1ms filtering) | Command output delay ≤80μs (100μs for the previous generation); output status readback delay ≤40μs (50μs for the previous generation) |

| Protection Mechanism | Photoelectric isolation between channels (2.5kVrms, 2kVrms for the previous generation); reverse connection protection (input voltage -30V~30V) | Photoelectric isolation between channels (2.5kVrms); short-circuit protection (triggered when current >6A, response ≤0.5μs) (3A/1μs for the previous generation); over-temperature derating protection (when internal temperature >70℃) |

2. Redundancy and Power Supply Parameters (New Upgrades)

| Parameter Category | Specific Specifications (Upgrades Compared to IS220PDIOH1A) |

|---|---|

| Redundancy Design | Dual Ionet bus (100Mbps full-duplex, switching time ≤0.3ms, 0.5ms for the previous generation) + dual-power input (24V DC A/B channels with independent rectification); 1:1 redundant backup for MCU/DO driver chips (only key circuits were backed up in the previous generation) |

| Power Supply Adaptability | Input voltage range: 24V DC±30% (±20% for the previous generation); maximum power consumption ≤25W (16-channel DI + 16-channel DO under full load of 4A, 20W for the previous generation); power supply ripple rejection ratio ≥60dB (at 100Hz) |

| Data Storage | 128MB Flash (64MB for the previous generation) + 64MB RAM (32MB for the previous generation), supporting 10 years of fault log storage (non-volatile even when power is off) |

3. Environmental and Reliability Parameters (Expanded Optimization)

| Parameter Category | Specific Specifications (Expansions Compared to IS220PDIOH1A) |

|---|---|

| Operating Temperature | -30℃~75℃ (natural heat dissipation); storage temperature: -40℃~85℃ (the previous generation had an operating temperature of -20℃~70℃) |

| Vibration/Shock Resistance | Vibration: 10-500Hz, 3g acceleration (IEC 60068-2-6, 2g for the previous generation); Shock: 50g/11ms (half-sine wave, IEC 60068-2-27) |

| Electromagnetic Interference Resistance | Emission: EN 55032 Class B (consistent with the previous generation); Immunity: ESD ±10kV (contact)/±15kV (air, ±8kV contact for the previous generation), EFT ±4kV (power supply/signal, consistent with the previous generation) |

| Protection Level & Dimensions | IP20 (consistent with the previous generation); Dimensions: 140mm×175mm×85mm (3U height), weight ≤2.5kg (2.2kg for the previous generation, slightly increased due to enhanced drive circuits) |

III. Functional Features

1. 4A High-Power DO Drive, Simplifying High-Load Control Architecture

Addressing the pain point in industrial scenarios where "high-power actuators require additional amplification modules", the IS220PDIOH1B enhances DO driving capability:

- Direct Drive of High-Load Equipment: The single-channel 4A continuous output can directly drive motor contactors below 3kW and 4A solenoid valves (e.g., Schneider LC1D series contactors). In the blast furnace control system of a metallurgical plant, it replaces the combination of "DI/DO module + power amplifier", reducing the number of equipment by 40% and the space occupied in the control cabinet by 35%.

- 10A Peak Output for Startup Surge: Motors and solenoid valves have instantaneous large currents during startup (e.g., 8A peak current for contactor pull-in). The 10A/100ms peak output can avoid false triggering of DO protection during startup. In the motor start-stop process of a heavy machinery factory, the DO false protection rate is reduced from 5% to 0.

- Grouped Independent Drive: DO channels are divided into groups with independent drive circuits (2 channels per group). When a DO channel in a group is short-circuited, only that group is affected (the previous generation had 4 channels per group), reducing the fault scope by 50%. For example, if one DO channel is short-circuited in a chemical plant, only 2 DO channels are temporarily offline, while the other 14 channels operate normally (the previous generation required shutdown for troubleshooting).

2. Wide Temperature Range (-30℃~75℃) + 3g Vibration Resistance, Adapting to Extreme Working Conditions

Targeting extreme industrial environments such as severe cold, high temperature, and high vibration, the module’s hardware is fully upgraded:

- Low-Temperature Startup Optimization: It uses -55℃ startup capacitors and wide-temperature MCUs (-40℃~105℃). In a northeastern power plant with an ambient temperature of -28℃ in winter, the module works normally 0.5 seconds after power-on (the IS220PDIOH1A requires 5 minutes of preheating), avoiding delays in unit startup in winter.

- High-Temperature Derating Protection: A built-in temperature sensor monitors the module temperature. When the temperature exceeds 70℃, the DO current is automatically reduced from 4A to 2A. Around the heating furnace of a metallurgical plant (ambient temperature 72℃), the module operates continuously for 30 days without overheating faults (the previous generation module is prone to shutdown due to overheating).

- High-Vibration Adaptability: The PCB board adopts a reinforced fixing design (metal bracket + anti-vibration glue), and components use anti-vibration packaging (e.g., ceramic chip resistors). In a rolling mill vibration environment (3g), the DI signal acquisition fluctuation is ≤±1%, and the DO output is uninterrupted (traditional modules are prone to poor contact under vibration).

3. Reinforced Redundancy with Dual Power Supplies + Dual Buses, Improving System Reliability

To meet the "zero shutdown" requirement of high-load equipment, the module’s redundancy design is fully upgraded:

- Independent Dual-Power Input: 24V DC A/B channels provide independent power supply. When a single power channel fails, it switches to the backup power supply within 0.1ms. In the steam turbine system of a thermal power plant, when the A-channel power supply is interrupted due to lightning strikes, the B-channel takes over seamlessly without data loss (the previous generation only had a single power input and required external UPS backup).

- Accelerated Bus Switching: The Ionet bus switching time is reduced from 0.5ms to 0.3ms. In a gas turbine control system, when the main bus is interrupted by interference, the backup bus resumes communication within 0.3ms, and there is no delay in DO commands (the switching delay of the previous generation may cause valve misoperation).

- Chip-Level Redundant Backup: MCU and DO driver chips adopt 1:1 redundant backup. When a single chip fails, it switches to the backup chip within 0.05ms. In the auxiliary system of a nuclear power plant, the DO driver chip fails and switches to the backup without perception, without affecting valve control (the previous generation required replacement of the entire module).

4. Upgraded Intelligent Diagnosis, Simplifying Operation and Maintenance

Through the optimization of hardware sensors and software algorithms, the module’s operation and maintenance efficiency is significantly improved:

- Single-Channel Fault Location: DO supports dual diagnosis of open circuit/short circuit. When a DO channel is open, the software directly displays "Channel 12 DO Open Circuit" (the previous generation only prompted "DO Fault"), reducing the troubleshooting time for maintenance personnel from 2 hours to 10 minutes.

- Temperature Early Warning Mechanism: An early warning signal is sent when the internal temperature exceeds 65℃ (below the derating threshold). In the heating furnace control system of a steel plant, the module issues an early warning of overheating (due to a faulty cooling fan) 3 days in advance, avoiding shutdown for maintenance.

- Historical Fault Tracing: The 128MB Flash stores 10 years of fault logs (including temperature, voltage, and current at the time of the fault). A power plant analyzed the logs and found that "monthly DO short circuits" were related to motor startup surges. The fault was eliminated after adjusting the startup sequence.