Description

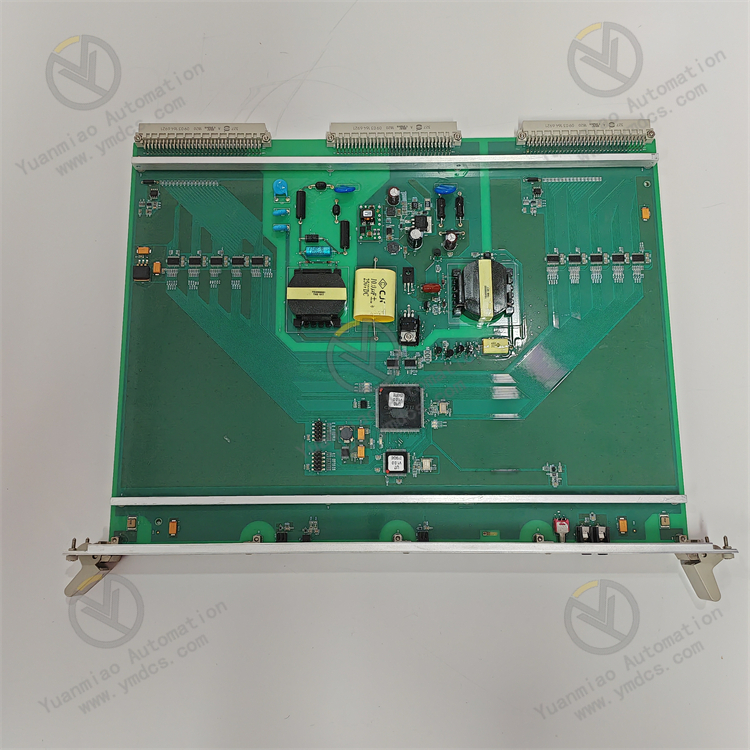

GE IS220PAICH2A

The GE IS220PAICH2A is a highly integrated AI/AO (Analog Input/Analog Output) all-in-one module designed for the Mark VIe control system. It needs to be used in conjunction with Mark VIe main controllers (such as the IS220PPROH1A), analog sensors (4-20mA pressure transmitters, PT100 temperature sensors), analog actuators (4-20mA control valves, 0-10V frequency converters), and the Ionet redundant bus. Its core functions focus on "AI/AO integration, high precision, and high reliability", including the following specific features:

It supports 16 channels of isolated analog input (AI, compatible with 4-20mA/0-10V/PT100/PT1000) plus 16 channels of isolated analog output (AO, compatible with 4-20mA/0-10V). A single module realizes "multi-parameter acquisition + precise control", replacing 2 independent modules and reducing the space occupied in the control cabinet by 50%.

The AI channels have a 16-bit resolution, with an acquisition accuracy of ±0.05% FS (at 25°C) and ±0.1% FS (within -20°C to 70°C); the AO channels have an accuracy of ±0.08% FS (at 25°C) and ±0.15% FS (within -20°C to 70°C). The synchronization delay between AI and AO is ≤100μs, which meets the requirements of multi-parameter coordinated control (e.g., the linkage of "pressure acquisition - fuel regulation" for gas turbines).

It is equipped with dual Ionet bus ports (100Mbps full-duplex). When the main bus fails, it switches to the backup bus within 0.5ms without data loss; key circuits (ADC/DAC chips, power supply) have dual backups. When a single circuit fails, it switches to the backup circuit within 0.1ms, with a Mean Time Between Failures (MTBF) of ≥110,000 hours.

The operating temperature range is -20°C to 70°C, and the storage temperature range is -40°C to 85°C. It adopts a metal shielded housing (with a shielding effectiveness of ≥50dB) and channel optoelectronic isolation (2kVrms), enabling resistance to electromagnetic interference (e.g., around 10kV frequency converters). It is suitable for harsh industrial environments such as power plants and metallurgical facilities.

It has a built-in 32-bit MCU, supporting AI open-circuit/short-circuit diagnosis (response time ≤1μs), AO overcurrent/overvoltage protection (triggered when AO overcurrent exceeds 30mA), and temperature drift compensation (temperature drift ≤±0.02% FS/°C within -20°C to 70°C). The AI/AO range and signal type can be configured via GE Control ST software, and online calibration is supported (no need to disassemble the module).

In gas turbine control applications, the IS220PAICH2A collects fuel pressure and exhaust temperature through 16 AI channels and drives fuel control valves via 16 AO channels. The synchronization delay between AI and AO is ≤80μs, reducing the fuel regulation accuracy from ±0.5% to ±0.1% and increasing the unit power generation efficiency by 0.8%. In the hydraulic control of rolling mills in a metallurgical plant, the module resists electromagnetic interference (around 10kV frequency converters), with the AI acquisition pressure fluctuation ≤±0.02% FS, and the AO output controls the rolling mill pressure stably (traditional modules have a fluctuation of ±0.1%, leading to product thickness deviation). In the control of a chemical reactor, the module's temperature drift compensation reduces the temperature control error from ±1°C to ±0.2% at 40°C, increasing the product qualification rate by 3%.

To meet the demand for "multi-parameter acquisition + precise control" in industrial scenarios, the module reduces the number of devices through integrated design:

The integration of 16 AI channels and 16 AO channels replaces the combination of "a 16-channel AI module + a 16-channel AO module". In a gas turbine control system, the number of modules is reduced from 6 to 3, cutting the space occupied in the control cabinet by 50% and reducing wiring work by 60%.

The synchronization delay between AI acquisition and AO output is ≤100μs. In the pressure control of a steam turbine, the AO outputs a valve adjustment command within 100μs after the AI collects the pressure signal, reducing the pressure control fluctuation from ±0.05MPa to ±0.01MPa.

AI is compatible with current/voltage/RTD, and AO supports current/voltage output. In a chemical reactor system, one module simultaneously collects 8 channels of temperature (PT100) and 8 channels of pressure (4-20mA), and drives 8 control valves (4-20mA) and 8 frequency converters (0-10V) without additional modules, increasing integration efficiency by 70%.

To meet the demand for "precision control", the module achieves extreme accuracy through hardware optimization:

Adopting a 16-bit Δ-Σ ADC and temperature drift compensation algorithm, in the auxiliary feedwater system of a nuclear power plant, the AI pressure acquisition error is reduced from ±0.2% FS to ±0.03% FS, and the feedwater flow control accuracy is increased to ±0.3%.

Equipped with a 16-bit DAC and a low-ripple drive circuit, in the hydraulic control of a precision machine tool, the AO output ripple is ≤10mV, ensuring no jitter of the hydraulic valve core and improving the machine tool processing accuracy from ±0.02mm to ±0.005mm.

The PT100 channel supports 3-wire/4-wire lead resistance compensation (adjustable from 0-10Ω). In the bearing temperature monitoring of a metallurgical rolling mill, the temperature error is reduced from ±0.5°C to ±0.1°C, enabling an early warning of bearing overheating 3 hours in advance.

To meet the "zero downtime" demand of medium and large-scale equipment, the module enhances redundancy design:

The main and backup buses transmit data synchronously. When the main bus is interrupted due to electromagnetic interference, it switches to the backup bus within 0.5ms. In the steam turbine system of a thermal power plant, there is no data loss during bus switching and no pressure control fluctuation (traditional modules have a fluctuation of ±0.03MPa during switching).

ADC/DAC chips and power supply circuits have 1:1 redundant backups. When a certain ADC fails, it switches to the backup ADC within 0.1ms, ensuring uninterrupted fuel pressure acquisition of the gas turbine.

It supports online calibration of AI/AO accuracy via GE Control ST software (no need to disassemble the module). A chemical plant conducts online calibration once a quarter, maintaining the accuracy within ±0.05% FS and avoiding downtime caused by traditional offline calibration.

Aiming at harsh environments such as power plants and metallurgical facilities, the module undergoes a comprehensive upgrade in hardware protection:

With a metal shielded housing (≥50dB), channel optoelectronic isolation (2kVrms), and twisted-pair input/output, around 10kV frequency converters (with electromagnetic radiation of 50V/m), the AI acquisition fluctuation is reduced from ±0.1% FS to ±0.02% FS, and the AO output is free from interference.

Using low-temperature-resistant capacitors (starting at -40°C) and wide-temperature MCUs (-40°C to 105°C), in a northeastern power plant at -18°C in winter, the module works normally 0.3 seconds after power-on (traditional modules require 3 minutes of preheating).

It provides real-time diagnosis of AI open-circuit/short-circuit and AO overcurrent/overvoltage. When a certain AO is short-circuited, the output is cut off within 1μs, preventing module burnout caused by short circuits in the control of heating furnaces in an iron and steel plant.

![]()