Description

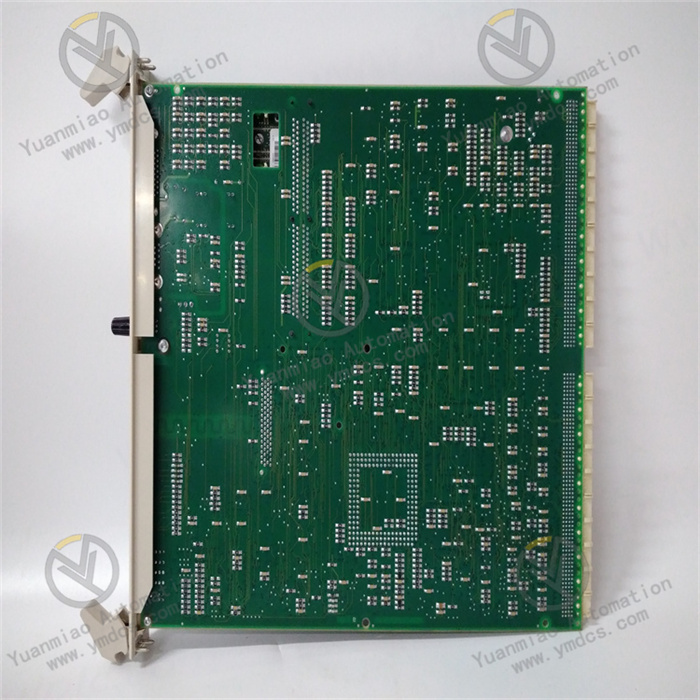

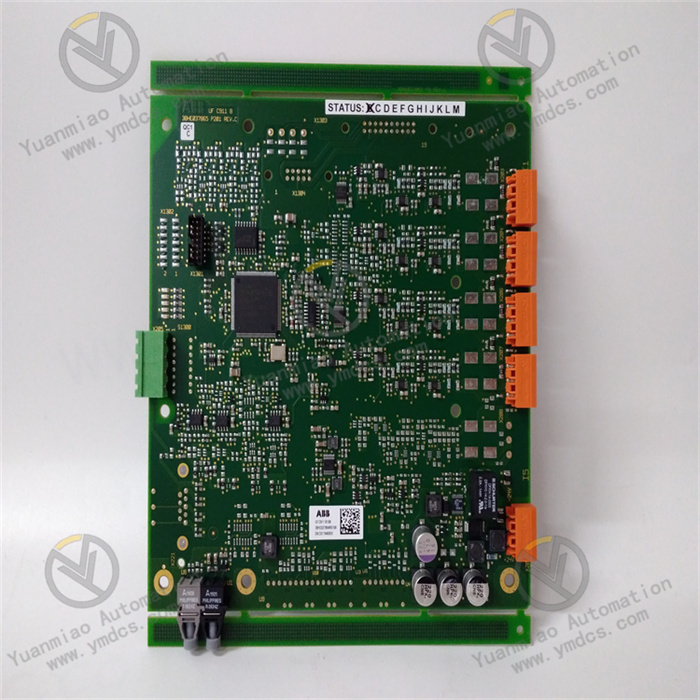

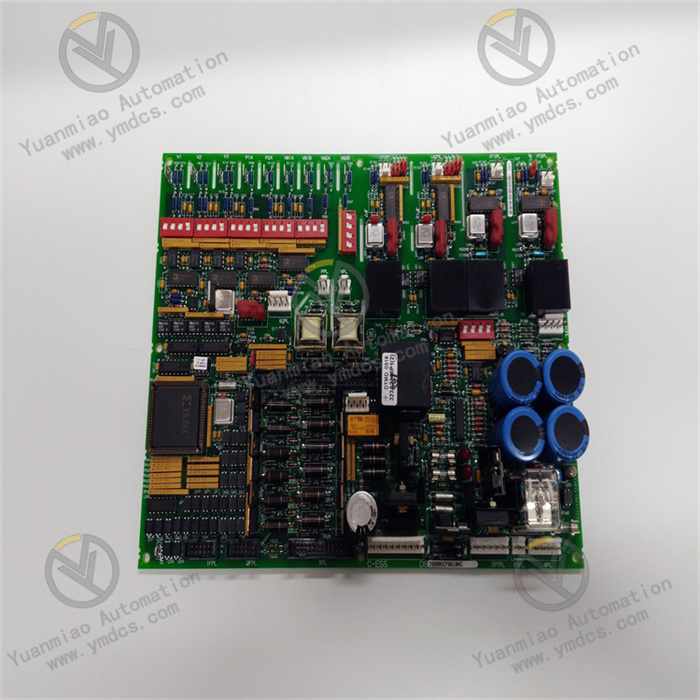

ABB PM511V16 3BSE011181R1

The ABB PM511V16 3BSE011181R1 is a processor module applied in the field of industrial automation.

Hardware Parameters

- Dimensions and Weight:

Some sources indicate its dimensions are approximately 150mm×100mm×40mm, with a weight of 0.76kg. Other references mention a net depth/length of 274.5 mm, net height of 27 mm, net width of 270 mm, and net weight of 0.8 kg. - Memory:

Typically featuring 16MB of memory capacity, equipped with 8MB of Dynamic Random Access Memory (DRAM) with Error-Correcting Code (ECC) to ensure data integrity. It also supports Type II PCMCIA flash cards with a maximum capacity of 64MB. - Processor Speed:

Some data shows a speed of 32MHz, while others mention a high-performance processor with a clock speed of 1.2GHz, capable of rapidly executing complex control algorithms and data processing tasks. - Power Supply:

Input voltage is 24VDC, with a power consumption of 5W. - Communication Ports:

Equipped with 1 RS-232 port, 1 RS-485 port, and 1 10/100Base-T Ethernet port.

Performance Parameters

- Control Accuracy:

Control accuracy can reach ±0.1%. - Operating Temperature:

The operating temperature range is -20°C to +60°C, with some sources indicating -25°C to +70°C. - Output Frequency:

The maximum output frequency can reach 60kHz.

Functional Features

- Programming Languages:

Supports multiple programming languages, such as Function Block Diagram (FBD), Structured Text (ST), and Ladder Diagram. - Communication Protocols:

Compatible with multiple communication protocols, including Modbus, Profibus, CANopen, Ethernet/IP, and Profinet, facilitating communication and data exchange with other devices. - High Reliability:

With ECC soldered memory and flash storage, it offers a long lifecycle, seismic resistance, and reliable data storage, ensuring stable operation even in harsh environments or extended temperature conditions.

Application Fields

- Industrial Automation:

Used for equipment control on production lines, factory automation systems, and process control in various manufacturing industries to achieve precise monitoring and optimization of production processes. - Power Systems:

Applied in power generation, transmission, and distribution to monitor and control power equipment, as well as for the automated management of power systems, helping improve power system stability and efficiency. - Chemical Industry:

Suitable for various control tasks in chemical production processes, such as chemical reaction process control and material transportation control, ensuring the safety and efficiency of chemical production. - Other Fields:

Also widely used in industries such as transportation, food and pharmaceuticals, building automation, and automotive and aerospace for corresponding control and monitoring systems.

Operation Essentials

- Installation:

Install according to the product manual, ensuring the installation environment avoids harsh conditions such as humidity, high temperature, and high pressure. The module typically has specific installation methods and fixing requirements to ensure secure mounting. - Wiring:

Strictly follow the wiring diagram to connect input and output lines, ensuring correct power supply wiring and reliable communication line connections with other devices to avoid equipment damage or malfunctions due to wiring errors. - Programming and Configuration:

Use supported programming software to write control programs according to specific application requirements and configure various parameters of the controller, such as communication parameters and control algorithm parameters. After programming, download the program to the module. - Operation and Monitoring:

During module operation, real-time viewing of its operating status, variable values, I/O signal status, and other information can be achieved through programming software or a host monitoring system to promptly identify and adjust issues. Meanwhile, pay attention to the indicator light status on the module to understand its working conditions. - Maintenance and Servicing:

Regularly clean and inspect the equipment to ensure the surface is free of dust and debris, and check for loose connection lines. Carry out comprehensive inspections and tests according to specified maintenance cycles, and promptly replace aging or damaged components to extend the equipment's service life.