Description

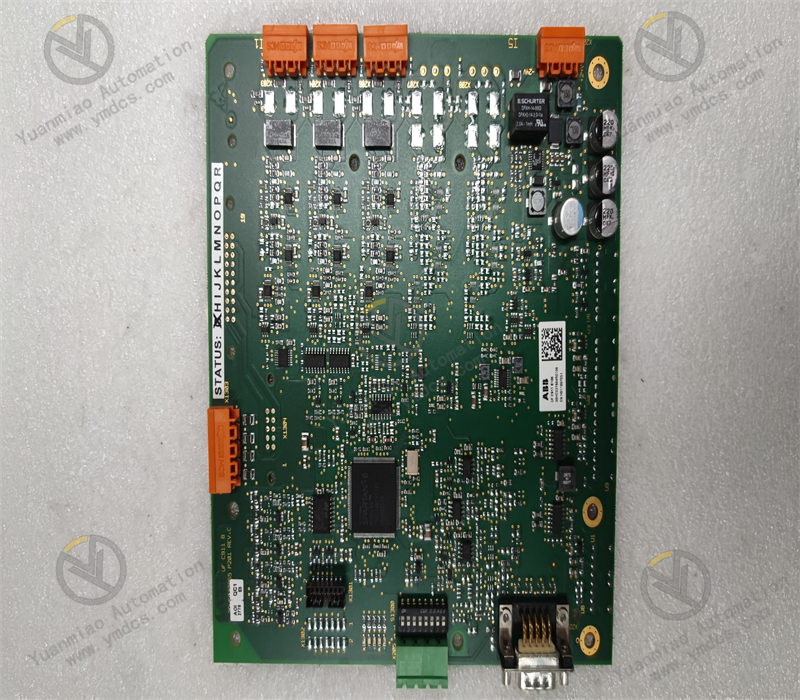

ABB PM803F 3BDH000530R1

The ABB PM803F 3BDH000530R1 is a high-performance PLC unit in the AC 800F series and serves as the core unit of the ABB Advant Controller 800xA system. As a basic component of the PLC, it is used to achieve process control, data processing, and communication functions. It is a modular and highly reliable controller suitable for various industrial automation scenarios.

Key Functions and Technical Features

Processor Performance

- Equipped with an Intel 32-bit RISC processor or ARM Cortex A8 processor, with a maximum clock speed of 400 MHz, offering strong processing capabilities to meet complex control requirements.

Memory

- Features 16 MB RAM with battery backup to ensure data integrity during power failures.

Communication Interfaces

- Supports multiple communication protocols and interfaces, such as Modbus, PROFIBUS, RS-232/RS-485, and Ethernet, facilitating data exchange and integration with other devices and systems.

Signal Processing

- Provides common signal processing functions including digital input/output and analog input/output, enabling connection to various sensors and actuators for precise control of industrial processes.

Environmental Adaptability

- Operates at a DC 24V power supply with ±20% voltage tolerance and a wide temperature range of -25°C to +70°C, adapting to harsh industrial environments and diverse power conditions.

Redundancy Design

- Supports redundancy design to enhance system reliability and availability, reducing production downtime caused by equipment failures.

Programming and Configuration

- Users can develop applications and customize configurations using specific programming languages such as ABB's ControlBuilder M to meet diverse industrial needs.

Technical Parameters

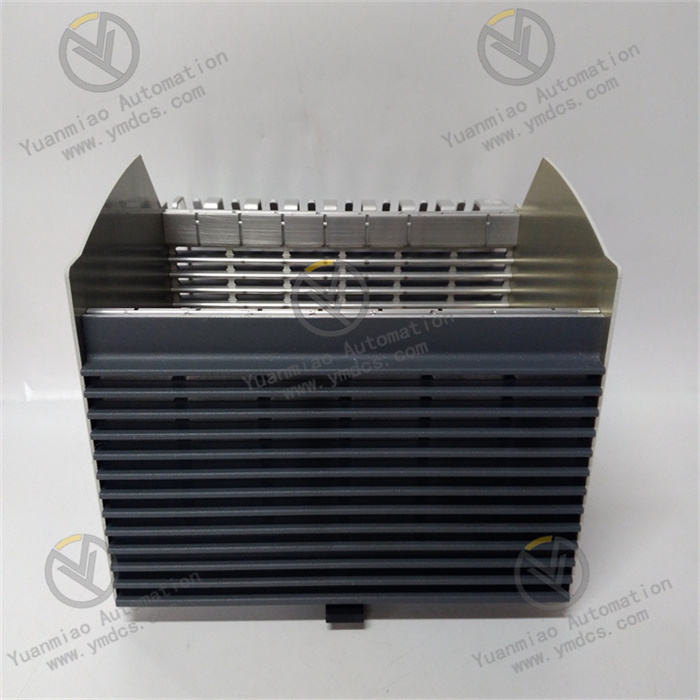

- Dimensions: 239 mm (L) × 164 mm (W) × 202 mm (H)

- Weight: 1.6 kg

- Software Requirements: Requires V7.1SP2a or higher version software.

- Hardware Configuration: 16MB basic unit, battery-buffered RAM, equipped with a special contact rack RW855F.

- Performance Features: Belongs to ABB's Freelance series and serves as the basic unit of the AC800F field controller (PLC). It has 5%-10% lower performance than the obsolete PM802F and supports multiple programming languages such as Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST).

Application Scenarios

Manufacturing

- Used for production line control and automation to precisely manage production processes, improving efficiency and product quality.

Power Systems

- Monitors and controls power equipment in power generation, distribution, and transmission to ensure stable operation of the power system.

Water Treatment

- Manages automation in wastewater treatment and tap water production, including water quality monitoring, pump control, and chemical dosing systems.

Petrochemical Industry

- Controls processes in refineries and chemical plants, real-time monitoring and regulating parameters such as temperature, pressure, and flow to ensure production safety and quality.

Building Automation

- Integrates and manages HVAC, lighting, and security systems to enable intelligent control of building equipment, improving energy efficiency and comfort.

Operation Guide for ABB PM803F 3BDH000530R1

Preparations

- Familiarize with the Module: Understand technical parameters such as the 24V DC (±20%) power supply, dimensions (239×164×202 mm), and weight (1.6 kg).

- Prepare Tools and Software: Ensure necessary installation tools (e.g., screwdrivers) and compatible programming/configutation software (e.g., ABB automation engineering software) are ready.

- Hardware Inspection: Check the module for physical damage and ensure all interfaces and slots are intact.

Installation

- Location Selection: Install in an indoor environment with a temperature range of -25°C to +70°C, avoiding humidity, dust, corrosive gases, and strong electromagnetic interference.

- Rail Mounting: Secure the module on a DIN rail to prevent looseness.

- Power Connection: Connect the positive and negative poles of the 24V DC power supply to the module’s terminals, ensuring correct polarity.

- Communication and Device Connection: Use appropriate cables to connect the PM803F’s communication interfaces (e.g., Ethernet, serial ports) to other devices (e.g., host computers, I/O modules). Properly connect analog/digital input/output devices as required.

Configuration and Programming

- Software Setup: Launch the configuration software, establish a communication link with the PM803F, create a new project or open an existing one, and add the PM803F module to the project.

- Parameter Configuration: Set parameters such as communication settings (IP address, subnet mask, protocol), I/O channel parameters (analog/digital ranges and logic), timer/counter values, and PID control loop parameters.

- Programming: Write control logic using supported languages (LD, FBD, ST), compile the program, and download it to the PM803F.

Operation and Maintenance

- Real-Time Monitoring: Use configuration software or a host computer to monitor the module’s status, including I/O values and status indicators. Watch for alarms or anomalies.

- Routine Maintenance: Regularly check for loose connections and clean the module. Update the firmware periodically as recommended by ABB to optimize performance and stability.

- Fault Handling: Identify fault causes through alarm messages, status indicators, and diagnostic functions. Resolve simple issues using the manual; contact ABB technical support for complex faults.

SM811 Module Synchronization (if applicable)

- Preparation: Ensure the synchronization link between SM811 modules is connected with a closed TK852V010 cable.

- Module Insertion: Insert the SM811 into its slot.

- Indicator Observation: The synchronization LED will flash when the SM811 starts, followed by three sequential flashes and a pause.

- Confirmation: Create an edge on digital input 3 of the active main safety module (e.g., via a physical button). Press the button to confirm when the synchronization LED repeats the three-flash-and-pause sequence.

- Synchronization Completion: The synchronization LED will flash faster until completion, turning yellow. Note: For SIL3 applications, user confirmation of synchronization is required within 30 minutes; otherwise, the inserted SM811 will shut down and require reinsertion. Non-SIL and SIL1-2 applications are unaffected and continue normal operation during synchronization.