Description

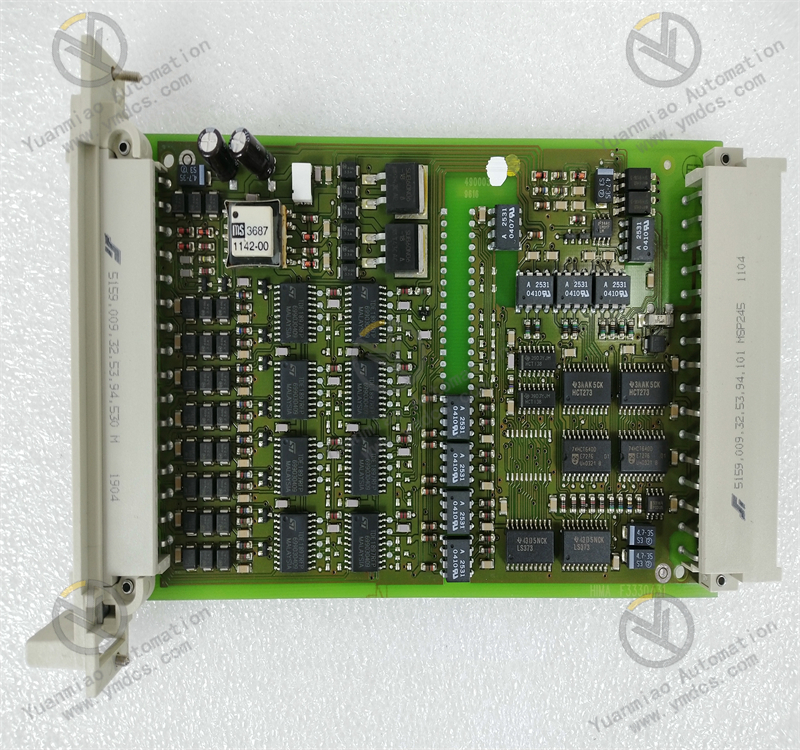

- It usually comes in a compact modular design, which is convenient for installation and integration into different control cabinets. Its dimensions and weight are designed to fit into standard industrial equipment spaces, facilitating easy handling and installation by technicians.

- It operates within specific voltage and current ranges. For example, it might be designed to work with a nominal voltage of 24V DC, with a certain allowable voltage tolerance range to ensure stable operation under different power supply conditions. The current consumption varies depending on the specific operating mode and the connected peripheral devices.

- Input/Output Capabilities: It is equipped with multiple input and output channels. The input channels can receive various types of signals, such as digital signals from sensors indicating the status of equipment (on/off, limit switch positions, etc.) and analog signals representing physical quantities like temperature, pressure, and flow. The output channels, on the other hand, are used to control actuators such as motors, solenoid valves, and relays, enabling precise control of industrial processes.

- Programmable Logic Control: It has programmable logic capabilities, allowing users to configure and customize the control logic according to specific process requirements. This is typically achieved through programming languages such as ladder logic, function block diagram, or structured text. Users can define complex control sequences, including conditional statements, loops, and timers, to achieve the desired automation functions.

- Communication Interfaces: It is equipped with various communication interfaces to enable seamless integration with other devices and systems in the industrial network. Common interfaces include Ethernet for high - speed data transfer and connection to supervisory control and data acquisition (SCADA) systems, as well as serial interfaces like RS - 485 for communication with other local devices in a multi - drop network configuration. This allows for easy exchange of data and commands between different components of the automation system, facilitating centralized monitoring and control.

- Manufacturing Industry: In manufacturing plants, it is used to control production lines, such as controlling the movement of conveyor belts, the operation of robotic arms, and the sequence of operations in assembly processes. It ensures the smooth and efficient operation of the production line, improving production efficiency and product quality.

- Process Industry: In industries such as chemical, oil and gas, and water treatment, the SB510 is used to monitor and control process variables. It can adjust the flow rate of chemicals, control the temperature and pressure of reaction vessels, and ensure the safety and stability of the process.

- Building Automation: In commercial buildings, it can be used to control heating, ventilation, and air - conditioning (HVAC) systems, lighting systems, and access control systems. It helps to optimize energy consumption and provide a comfortable and safe environment for building occupants.

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage

![]()