Description

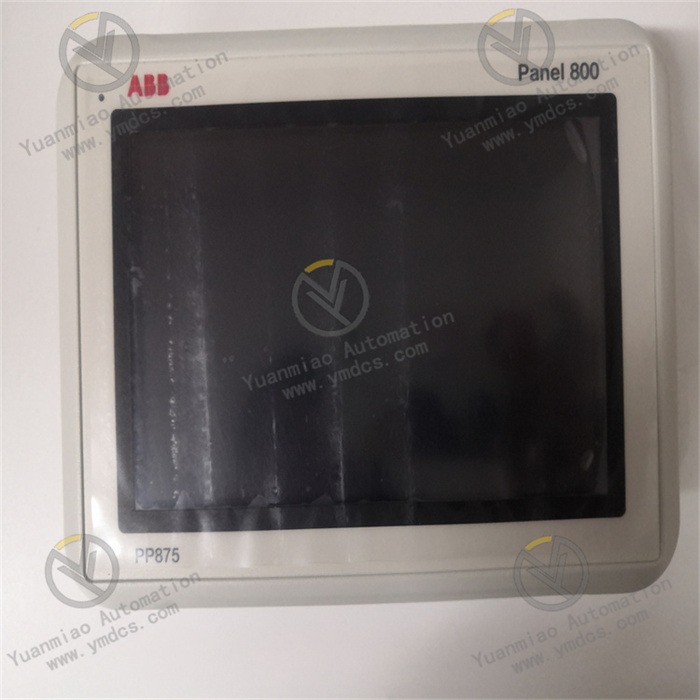

ABB PP875 3BSE092977R1

The ABB PP875 3BSE092977R1 is a communication module in the AC800M controller family. With multi-protocol compatibility, high-speed data processing capabilities, and industrial-grade durability, it is primarily used in industrial automation systems to enable multi-protocol communication, high-speed data interaction, and system expansion. It is suitable for scenarios such as distributed control systems (DCS), intelligent manufacturing, and process control. Its modular design and convenient configuration tools significantly reduce the integration and maintenance costs of industrial automation systems.

Core Functions and Features

1. Multi-Protocol Communication Capability

- Supported Protocols:

- Mainstream industrial protocols: Modbus RTU, Modbus TCP, CANopen, EtherNet/IP (requires configuration).

- Compatible with third-party devices (e.g., Siemens, Rockwell, Schneider), supporting cross-brand system integration.

- Application Scenarios:

- Connecting field devices such as sensors, variable frequency drives, servo motors, and smart instruments.

- Acting as a gateway to achieve conversion between different protocol networks (e.g., intercommunication between Modbus and EtherNet/IP).

2. High-Speed Data Transmission and Real-Time Performance

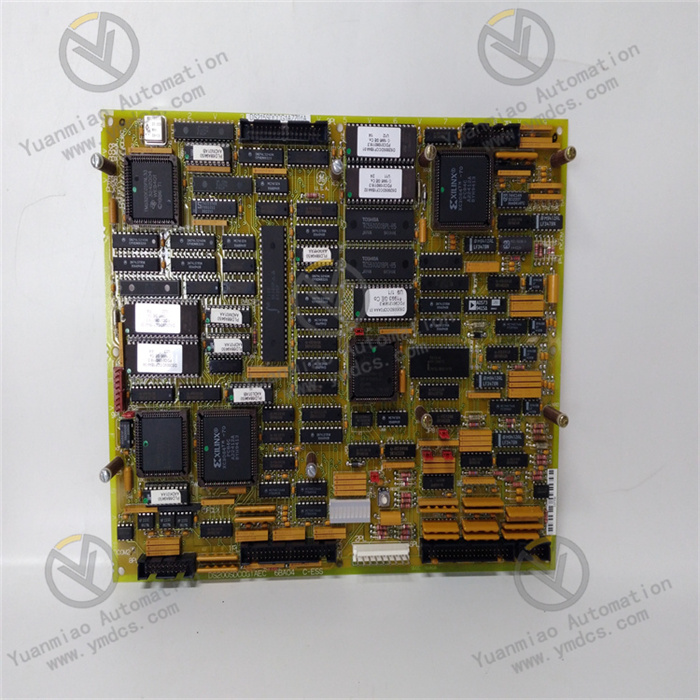

- Hardware Configuration:

- Built-in high-performance microprocessor supporting real-time data acquisition and low-latency transmission, meeting the requirements of high-real-time scenarios such as motion control and high-speed production lines.

- Backplane bus communication: Connected to AC800M CPU modules via MasterBus 300 with a transmission rate of up to 10 Mbps to ensure data synchronization efficiency.

- Data Processing:

- Supports parallel processing of multiple tasks (e.g., simultaneous parsing of Modbus TCP and CANopen data), with built-in buffers to avoid data congestion.

3. Industrial-Grade Reliability Design

- Environmental Adaptability:

- Operating temperature: -20°C ~ +60°C, adapting to harsh industrial environments such as high temperature, dust, and electromagnetic interference.

- Protection level: IP20 (suitable for installation in control cabinets), compliant with IEC 61000 electromagnetic compatibility standards, and resistant to vibration and shock (complying with IEC 60068-2 standards).

- Fault Diagnosis:

- Built-in self-diagnosis function to monitor interface status, power voltage, and module temperature in real time.

- LED indicators: RUN (operation status), FAULT (fault alarm), COMM (communication status), supporting quick anomaly location.

- Fault Response: Automatically retries connections, logs faults, and sends alarms to SCADA systems via controllers.

4. System Integration and Expansion

- Modular Design:

- As an expansion module for AC800M controllers, it seamlessly integrates with CPU modules via backplane buses without additional wiring.

- Supports cascading multiple communication modules to build flexible network topologies (e.g., star, bus, ring).

- Installation Method:

- DIN Rail mounting, saving control cabinet space and supporting hot-swapping (requires system power-off).

Technical Parameters

| Parameter Category | Detailed Specifications |

|---|---|

| Communication Interfaces | - 2 × RS-485 (supporting Modbus RTU, CANopen) - 1 × Ethernet (10/100 Mbps, Modbus TCP/EtherNet/IP) |

| Protocol Support | Modbus RTU/TCP, CANopen, EtherNet/IP (optional configuration), custom protocols (requires programming) |

| Transmission Rate | - RS-485: Up to 115.2 kbps - Ethernet: Auto-negotiating 10/100 Mbps |

| Power Supply | - Input voltage: 24 VDC (±20%) - Power consumption: Typical value <5 W |

| Physical Dimensions | Approximately 100 mm (H) × 25 mm (W) × 150 mm (D) |

| Compatibility | Compatible with AC800M series CPUs (e.g., PM866, PM867), requiring configuration via Control Builder M software |

Working Principle

1. Protocol Conversion and Data Interaction Flow

plaintext

Controller (AC800M CPU) → PP875 Module → Protocol Encapsulation/Parsing → Field Devices/Third-Party Systems Field Device Response → PP875 Module → Protocol Conversion → Controller/Supervisory Computers (e.g., SCADA, HMI)

- Example: When reading data from a Rockwell PLC via EtherNet/IP, the module converts AC800M's request into an EtherNet/IP message, sends it to the target IP address, and parses the response into a format recognizable by the controller after reception.

2. Coordination Mechanism with Controllers

- Backplane Bus Communication: Real-time exchange of control commands and feedback data with CPU modules via MasterBus 300 to ensure microsecond-level synchronization.

- Data Scheduling: Built-in priority queues give precedence to real-time control data (e.g., emergency shutdown signals) to guarantee response speed for critical tasks.

Typical Application Scenarios

1. Manufacturing Production Lines

- Connecting robots, PLCs, and vision inspection devices to achieve real-time status monitoring and equipment collaborative control on production lines (e.g., work order data distribution, fault shutdown linkage).

- Case Study: In an automotive final assembly line, the PP875 module collects sensor data from each workstation via Modbus TCP, uploads it to the MES system, and simultaneously receives production plan commands issued by the ERP.

2. Process Automation (Chemical/Power)

- Connecting distributed I/O modules or variable frequency drives via CANopen to achieve closed-loop control of complex processes (e.g., PID temperature regulation for chemical reaction kettles).

- Supports redundant communication configurations, acting as a primary/backup module switch in petrochemical scenarios to prevent system paralysis due to single-point failures.

3. Building Automation and Energy Management

- Serving as a Modbus/BACnet gateway to integrate HVAC systems, elevators, smart meters, and other devices, enabling building energy consumption data collection and linkage control (e.g., automatically adjusting air conditioning load based on room temperature).

4. Distributed Control Systems (DCS)

- In large factories (e.g., power plants, steel mills), cascading multiple PP875 modules to build multi-segment communication networks, achieving regionalized equipment management and cross-regional data sharing.

Selection and Matching Recommendations

1. Hardware Matching

- Controllers: Must be used with ABB AC800M series CPU modules (e.g., PM866, PM867), connected via backplane buses.

- Expansion Modules: Can be paired with ABB's I/O modules (e.g., DI810 digital input, AO810 analog output) to implement integrated "communication + control" solutions.

2. Software Support

- Configuration Tools: Use ABB Control Builder M for module parameter configuration, protocol mapping, and network topology design.

- Debugging Tools: Third-party software such as Modbus Poll (Modbus protocol debugging) and CANoe (CANopen protocol analysis) can assist with on-site debugging.

3. Alternatives and Upgrades

- For higher performance or broader protocol support, consider ABB's new-generation communication modules (e.g., PP880 series), which are compatible with emerging industrial Ethernet protocols such as EtherCAT and PROFINET.