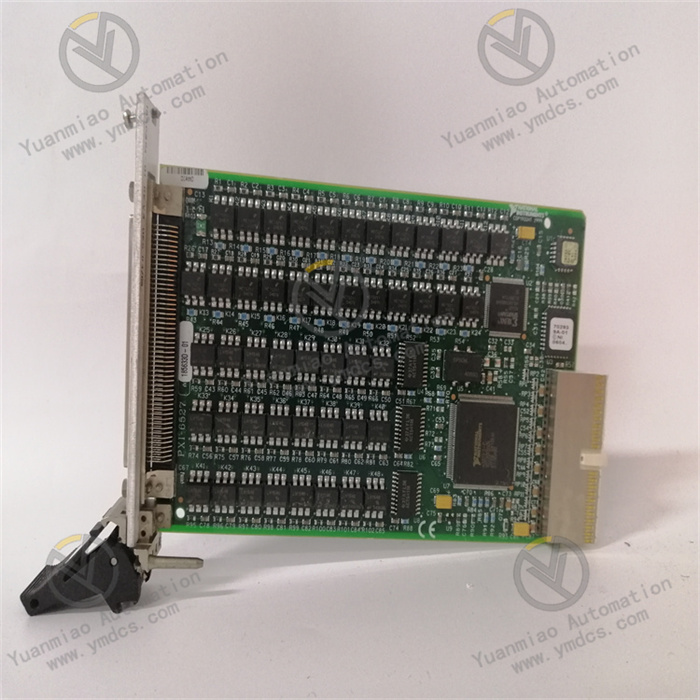

Description

Functional Features Powerful communication function: It supports multiple communication protocols such as Modbus TCP and Ethernet/IP, enabling convenient data interaction with other devices or systems, achieving interconnection and interoperability between different devices, and facilitating the construction of complex industrial automation control systems. High-speed data processing: It has strong data processing capabilities, capable of quickly processing and transmitting a large amount of data, ensuring the real-time performance and response speed of the system, and meeting the requirements for high-speed data processing in industrial production. For example, in a large-scale data collection and monitoring system, it can promptly process a large amount of data collected by sensors. High reliability: It adopts a robust hardware design and advanced circuit protection technology, enabling stable operation in harsh industrial environments. It has strong anti-interference capabilities and can withstand changes in temperature and humidity. It can adapt to industrial field environments with high temperature, high humidity, and strong electromagnetic interference, reducing system failures caused by environmental factors. Flexible configuration options: Users can flexibly configure the module according to actual application requirements, such as setting communication parameters and data transmission rates, to adapt to different industrial automation scenarios and meet various complex control requirements.

Technical Specification Parameters

Power supply voltage: Usually 24VDC, with a wide allowable voltage range, generally between 20.4 - 28.8VDC, capable of adapting to different power supply environments and ensuring stable operation of the module during power fluctuations.

Communication interface: Equipped with multiple Ethernet interfaces, supporting 10/100Mbps adaptive Ethernet communication, it can be conveniently connected to other devices that support Ethernet communication to achieve high-speed data transmission.

Data processing capability: It can handle a large amount of I/O data and communication data. The specific data processing speed and capacity depend on the complexity of the connected PLC system and application program. Generally, it can meet the needs of most industrial automation projects.

Application Areas Industrial automation production lines: It is used to achieve communication and collaborative work between various devices on the production line, such as automobile manufacturing production lines and electronic product assembly production lines. It can monitor and control the production process in real-time, improving production efficiency and product quality. Power systems: In power generation, transmission, and distribution systems, it can be used to achieve communication and remote monitoring between power equipment, such as substation automation systems and power dispatching systems, helping to improve the reliability and operation efficiency of the power system. Intelligent building control systems: It is used to connect various intelligent devices in buildings, such as air conditioning systems, lighting systems, and security systems, to achieve linkage control and centralized management between devices, creating an intelligent and energy-saving building environment. Water treatment systems: In water treatment facilities such as sewage treatment plants and waterworks, it can achieve remote monitoring and automated control of various water treatment equipment, such as water pumps, valves, and aeration equipment, improving the stability and efficiency of the water treatment process.

Installation and Maintenance Methods of Schneider 140CRP31200: Installation Methods Installation Environment Preparation Select a place that is dry, free of corrosive gases, and has little dust for installation. The ambient temperature should be between 0 - 55°C to ensure that the module can operate in a normal working environment. Avoid installing in locations with direct sunlight and large vibrations to prevent damage or unstable operation of the module due to environmental factors. Module Installation Ensure that all related devices are powered off before installation to prevent electric shock and device damage. Insert the 140CRP31200 module into the corresponding slot of the Quantum series PLC, ensuring a tight connection between the module and the slot. The slot is generally located on the PLC rack, and different rack models may vary slightly. Operate according to the installation guide of the corresponding model. Use tools such as a screwdriver to tighten the fixing screws of the module to ensure that the module will not loosen during operation. Wiring Connection Connect the power supply wiring according to the module instruction manual, ensuring that the power supply voltage meets the requirements of the module, generally 24VDC. Pay attention to the positive and negative polarities during wiring to avoid incorrect connection. Connect the communication cable, such as an Ethernet cable, to the Ethernet interface of the module, and ensure a firm connection to avoid communication failures caused by poor contact. Connect the other end of the communication cable to other devices for communication, such as switches and host computers.

Maintenance Methods Daily Inspection Regularly check the operation status indicator lights of the module. Under normal circumstances, the power indicator light, communication indicator light, etc. should be lit or flashing according to the specified status. If an indicator light is abnormal, such as being off, constantly on, or flashing at an abnormal frequency, it may indicate a corresponding fault in the module, and further inspection is required. Check whether there is dust accumulation on the surface of the module. If there is dust, gently wipe it with a clean soft cloth to avoid excessive dust affecting the heat dissipation of the module or causing a short circuit. Check whether the connection cables are loose. Gently shake the cables to check for poor contact. If loose, tighten the connection plugs or screws in a timely manner. Periodic Maintenance Conduct a comprehensive inspection of the module at regular intervals (such as every six months or once a year). Use professional tools, such as a multimeter, to measure whether the power input voltage is within the normal range to ensure stable power supply to the module. Check the connection of the communication interface. Check whether the communication is normal by sending test signals, etc. If there is a communication failure, troubleshoot the cause of the failure in a timely manner, such as checking the communication protocol settings and whether the cable is damaged. Back up the configuration files and related data of the module to prevent data loss due to module failure or other reasons. The data can be backed up to an external storage device or a host computer. Fault Handling If the module malfunctions, first refer to the user manual or technical documentation of the module to find the corresponding fault code and solution. For example, if there is a communication failure, the manual may prompt to check the communication parameter settings, network connection, etc. For some common faults, such as power supply faults and communication interface faults, you can try to replace the corresponding components, such as the power module and communication interface module. However, when replacing components, ensure that the replaced components are consistent with the original module model and operate according to the correct replacement steps. If the cause of the fault cannot be determined or the fault cannot be handled by yourself, contact the professional technical support personnel or after-sales service team of Schneider Electric in a timely manner. Have the fault repaired and handled by professional personnel to avoid the expansion of the fault due to incorrect operation.

Schneider Related Products

| 140XBP00600 | 140CPU41100 |

| 140AC013000 | 140CPU42401 |

| 140ACI04000 | 140CPU42402 |

| 140ACO02000 | 140CPU53414 |

| 140ACO13000 | 140CPU65160 |

| 140AVI03000 | 140CPU65260 |

| 140CHS11000 | 140CPU65860 |

| 140CHS11100 | 140CPU67060 |

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage