Description

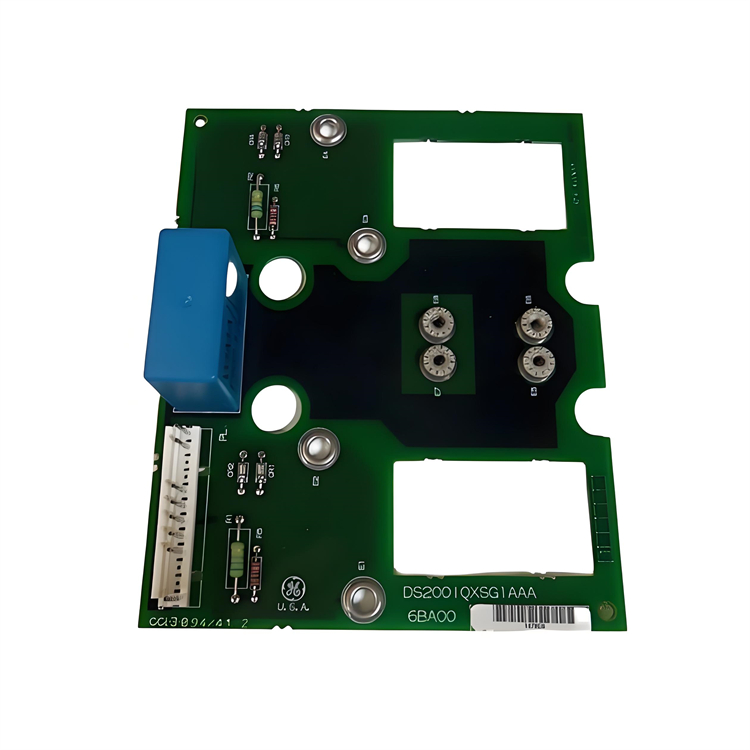

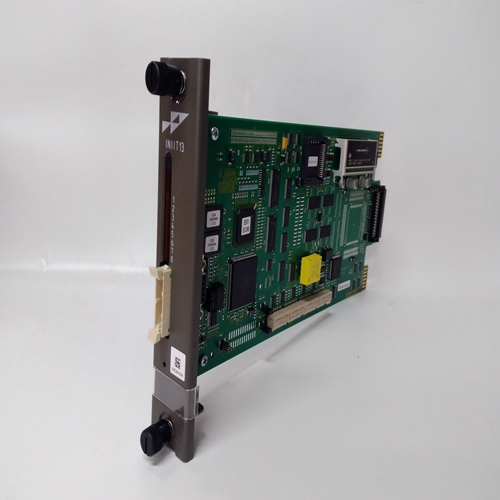

GE Multilin UR8NH

I. Overview

GE Multilin UR8NH is a CT/VT module meticulously developed by General Electric (GE) specifically for power system protection, monitoring, and control, belonging to the Universal Relay UR series. Leveraging GE's long-standing profound technical accumulation and rich practical experience in the power field, UR8NH integrates advanced signal processing technology and precise measurement algorithms. It is designed to provide accurate and reliable current and voltage data acquisition and processing services for various power systems, playing a crucial role in ensuring the stable and efficient operation of power systems.

II. Technical Parameters

(I) Input Characteristics

- Analog Input Types and Ranges: It can access up to 24 analog Current Transformer (CT) and Voltage Transformer (VT) signals, fully supporting two common rated current specifications of 1A and 5A. This broad input capability enables it to adapt to power systems of different scales and application scenarios. Whether it is a small distributed power station or a large regional grid substation, UR8NH can accurately collect current and voltage signals from various devices, providing basic data for subsequent protection and control decisions.

- Input Resolution and Accuracy: In the process of current and voltage signal acquisition, UR8NH exhibits extremely high resolution, being able to sensitively capture subtle changes in signals. For current measurement, the accuracy can reach ±0.2% FS (Full Scale), and the voltage measurement accuracy is as high as ±0.1% FS. Such high accuracy ensures precise monitoring of system operating parameters under complex power conditions, greatly reducing the risk of protection misoperation or abnormal equipment operation caused by measurement errors.

(II) Diagnostic Function Parameters

- Hardware Health Diagnosis: UR8NH closely collaborates with the standardized health diagnosis system of the Universal Relay series. At the initial start-up of the device, it conducts a comprehensive and detailed diagnostic evaluation of its own hardware health status in accordance with preset standard operating procedures. From core chips to peripheral circuits, and from signal input interfaces to data processing units, any potential hardware failure risks are difficult to hide. Moreover, during the entire normal operation cycle of the device, this health diagnostic monitoring will not be interrupted, continuously ensuring the stable operation of the module. Once a hardware abnormality is detected, such as chip overheating, circuit short circuit, etc., the module will immediately trigger the corresponding alarm mechanism through internal logic, and at the same time, record detailed fault codes and related data, facilitating maintenance personnel to quickly locate and solve problems, significantly improving equipment maintenance efficiency, and effectively reducing system downtime caused by hardware failures.

- Signal Integrity Diagnosis: For the connected CT and VT input signals, UR8NH has strong signal integrity diagnosis capabilities. It will real-time monitor the validity of signals, and through complex algorithm analysis, determine whether the signals have abnormal conditions such as distortion, interruption, and interference. For example, when there is an instantaneous electromagnetic interference in the power system, causing short-term fluctuations in CT or VT signals, UR8NH can quickly identify and distinguish them from real fault signals, avoiding unnecessary protection actions caused by misjudgment. At the same time, it will also continuously record the internal DC voltage level to timely detect potential power-related problems, take proactive maintenance measures in advance, and ensure that the module can operate stably and reliably under various working conditions.

(III) Power Parameters

- Supply Voltage Range: In terms of power supply, UR8NH has excellent adaptability and supports a wide range of DC voltage inputs. The low voltage range is 24 - 48V DC, which can meet the needs of some small power equipment or distributed power systems that have flexible power supply requirements and adopt low-voltage DC power supply; the high voltage range is 125 - 250V DC, which is suitable for scenarios with extremely high requirements for power supply stability and reliability, such as large substations and industrial power systems. This wide voltage range design enables UR8NH to work stably in different power infrastructure environments without the need for additional complex adaptation modifications due to differences in power supply voltage.

- Power Consumption: Under normal working conditions, the power consumption of UR8NH is very excellent, only about 4.5W. The low power consumption feature not only helps reduce the energy consumption of the entire power system and operating costs but also effectively reduces the heating problem during equipment operation, improving the stability and service life of the equipment. Especially in some application scenarios with strict requirements on energy efficiency and equipment heat dissipation conditions, such as power monitoring systems in data centers and intelligent monitoring units in distributed photovoltaic power stations, the low power consumption advantage of UR8NH is more prominent.

III. Functional Features

(I) Accurate Measurement and Signal Processing

- Advanced Measurement Algorithms: Built-in advanced measurement algorithms can process the collected current and voltage signals at high speed and accurately. These algorithms fully consider complex factors such as harmonic interference and frequency fluctuations common in power systems. Through technical means such as digital filtering and adaptive adjustment, they effectively remove noise interference and extract real and accurate fundamental wave signals, thereby achieving accurate measurement of power parameters. Whether it is accurate power calculation during steady-state operation or rapid fault current detection during transient faults, UR8NH can rely on its excellent algorithm performance to provide reliable data support for the protection and control of power systems.

- Signal Isolation and Anti-Interference: To cope with the complex and changeable industrial electromagnetic environment, UR8NH adopts multiple signal isolation technologies in hardware design. In the analog input channel, through high-performance isolation transformers and optocouplers, the external input signal is electrically isolated from the internal circuit, effectively blocking the conduction path of electromagnetic interference and preventing external interference signals from affecting internal data processing. At the same time, in the data transmission line, shielded cables and anti-interference wiring design are adopted to further enhance the module's resistance to electromagnetic interference. This all-round anti-interference measure ensures that UR8NH can still stably and accurately collect and transmit signals in high electromagnetic interference environments, such as large industrial plants and near high-voltage substations.

(II) High Integration and Flexible Configuration

- Modular Design Concept: Adopting a modular design concept, it perfectly adapts to the universal relay system. According to the scale and complexity of the actual power system, different numbers and types of UR8NH modules can be flexibly selected for combination. For small power systems, it may only need to configure 1 - 2 UR8NH modules to meet the current and voltage monitoring needs of key equipment; for large regional grid substations, multiple UR8NH modules can be cascaded to achieve comprehensive and detailed monitoring of many electrical equipment in the entire substation. This modular design not only improves the scalability of the system but also reduces the installation, commissioning, and maintenance costs of the equipment, providing great convenience for users.

- Software Configuration Flexibility: With the EnerVista Launchpad software platform, users can easily configure parameters and set functions for UR8NH. The software provides an intuitive and user-friendly graphical operation interface, supporting multiple languages, so that both experienced power engineers and technical personnel new to the power field can quickly get started. Through the software, users can flexibly adjust key settings such as the measurement range, alarm threshold, and communication parameters of the module according to the actual operation requirements of the power system, achieving personalized and refined monitoring and control of the power system. At the same time, EnerVista Launchpad also has powerful remote management functions. Users can remotely connect to the UR8NH module through the network, view the equipment operation status in real-time, and modify configuration parameters, which greatly improves the efficiency and convenience of equipment management.

(III) High Reliability and Stability

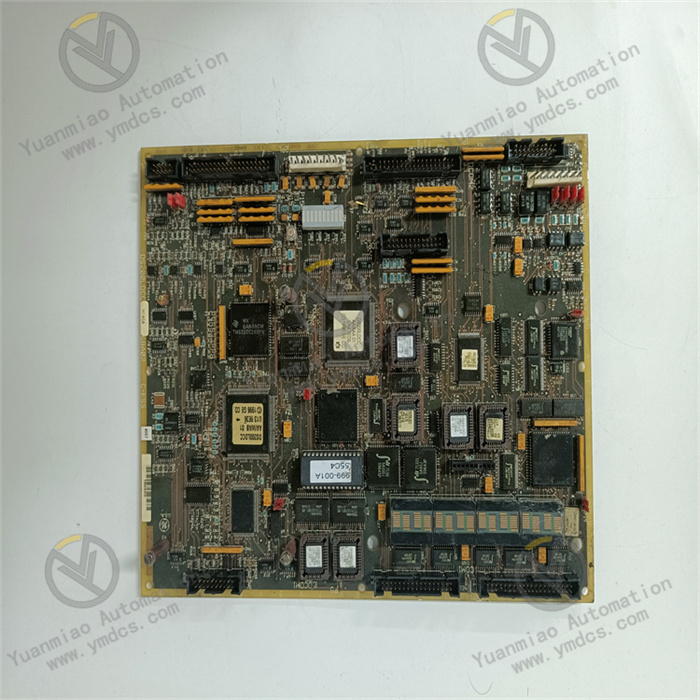

- Selection of Industrial-Grade Components: In the hardware manufacturing process, GE strictly selects industrial-grade high-quality electronic components. All components have undergone strict screening and aging tests to ensure that they can maintain stable and reliable performance in harsh industrial environments. From the core microprocessor to ordinary resistors and capacitors, each component is carefully selected to meet the strict reliability requirements of UR8NH under long-term and high-load operation conditions. This strict control over the quality of components lays a solid foundation for the high reliability and long service life of UR8NH.

- Redundant Design and Fault-Tolerant Mechanism: To further improve the reliability of the system, UR8NH adopts redundant design in key circuit parts. For example, in the power input circuit, a redundant power module is equipped. When one power module fails, the other power module can immediately switch seamlessly, continuing to provide stable power supply for the module, ensuring that the equipment will not shut down due to power failure. At the same time, in the data processing and storage links, a fault-tolerant mechanism is introduced. When data transmission errors or storage abnormalities occur, the system can automatically perform data verification and repair to ensure the integrity and accuracy of data. These redundant designs and fault-tolerant mechanisms greatly enhance the fault resistance of UR8NH under complex working conditions and effectively improve the stability and reliability of power system operation.

IV. Application Fields

(I) Substation Automation System

- Equipment Monitoring and Protection: In substations, UR8NH is responsible for real-time monitoring of current and voltage of various electrical equipment, such as transformers, circuit breakers, disconnectors, etc. Through accurate measurement and analysis of the operating parameters of these equipment, potential fault risks such as overheating, overload, and insulation aging of the equipment can be detected in a timely manner. For example, when the transformer winding has local overheating, its current and voltage will change slightly. UR8NH can quickly capture these changes, and by comparing with the preset alarm threshold, once it exceeds the threshold, it will immediately trigger an alarm signal, notifying maintenance personnel to take timely measures to avoid further expansion of the fault and ensure the safe and stable operation of substation equipment.

- Power Parameter Acquisition and Analysis: Provide comprehensive and accurate power parameters for the substation automation system, such as active power, reactive power, power factor, frequency, etc. These parameters are crucial for the economic operation scheduling, power quality evaluation, and power grid stability analysis of the substation. Through real-time acquisition and long-term data analysis of these parameters, maintenance personnel can deeply understand the operation status of the substation, optimize power scheduling strategies, improve energy utilization efficiency, reduce power grid losses, and ensure that the substation operates in an efficient and energy-saving state.

(II) Industrial Power Monitoring

- Power Distribution System in Large Industrial Enterprises: In large industrial enterprises such as steel, chemical, and metallurgical industries, the stable operation of the power system is directly related to the production efficiency and economic benefits of the enterprise. UR8NH can conduct all-round monitoring of the internal power distribution system of the enterprise, and real-time grasp the power consumption of each production workshop and important equipment. Through accurate monitoring of current and voltage, abnormal power consumption phenomena caused by equipment failures, line aging, etc., such as short circuits and electric leakage, can be detected in a timely manner, the fault circuit can be quickly cut off, the safety of equipment and personnel can be protected, production interruption caused by power failures can be avoided, and the economic losses of the enterprise can be reduced.

- Control of Industrial Automation Production Lines: It closely cooperates with various equipment in the industrial automation production line to provide accurate current and voltage feedback signals for the automation control system. In the automated production process, the operating state of the equipment is closely related to power parameters. By real-time monitoring the changes of power parameters, UR8NH can timely adjust the operating parameters of the equipment to ensure the stable operation of the production line. For example, in the automobile manufacturing production line, UR8NH can real-time monitor and control the power parameters of key equipment such as welding robots and painting equipment, ensuring the stability and accuracy of equipment operation, and improving product quality and production efficiency.

(III) Smart Grid and Distributed Energy Access

- Monitoring and Management of Distributed Power Sources: With the increasing proportion of distributed energy sources such as solar energy and wind energy in the smart grid, the monitoring and management of distributed power sources have become increasingly important. UR8NH can be used to monitor the output current and voltage of distributed power sources, such as photovoltaic power stations and wind farms, and real-time grasp their power generation status and power quality. Through the analysis of these data, the optimal scheduling and control of distributed power sources can be realized to ensure their safe and stable grid-connected operation with the power grid. For example, when the output power of a photovoltaic power station fluctuates due to changes in light intensity, UR8NH can timely detect changes in current and voltage, and transmit the data to the smart grid control system. By adjusting the working parameters of the inverter, the power fluctuation can be smoothed, and the power quality and reliability of the distributed power source can be improved.

- Microgrid Protection and Control: In the microgrid system, UR8NH, as a key monitoring and control module, conducts comprehensive monitoring of the power sources, loads, and lines in the microgrid. Through accurate measurement of current and voltage, real-time evaluation of the operation state of the microgrid can be realized, and faults can be detected and handled in a timely manner. For example, when a line short-circuit fault occurs in the microgrid, UR8NH can quickly detect the sudden change of fault current, quickly trigger the protection device, cut off the fault line, and protect the safe operation of other equipment in the microgrid. At the same time, it can also participate in the power balance control and energy optimization management of the microgrid according to the operation needs of the microgrid, improving the operation efficiency and reliability of the microgrid.