Description

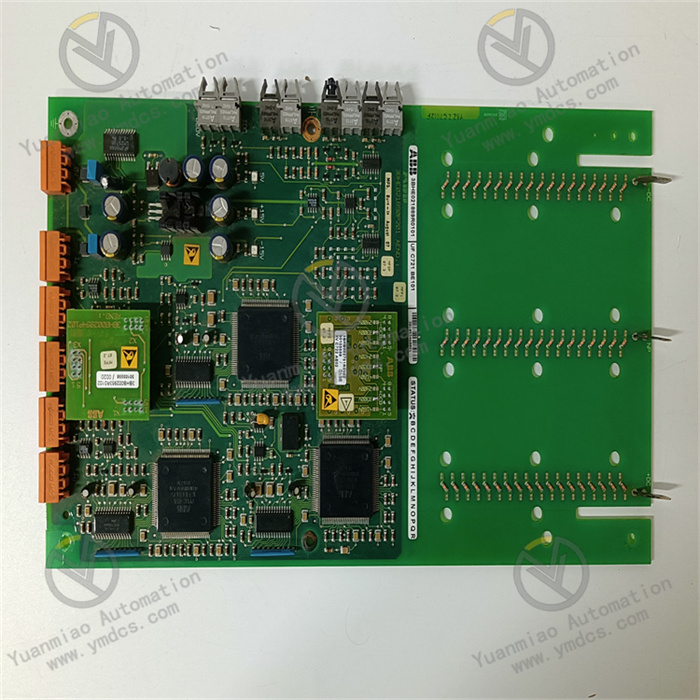

GE Multilin UR6DH

GE Multilin UR6DH is a digital I/O input/output module, part of the GE Multilin UR series of general-purpose relays. It is mainly used to connect various digital devices in UR devices to realize signal input and output.

Overview: UR6DH is specially designed for industrial automation, featuring modular design, high reliability and flexible configuration. Its main function is to collect digital signals from on-site equipment and convert them into digital signals recognizable by PLC, which are used for monitoring and controlling industrial processes.

Functional Features: It has multiple digital input and output channels, usually with 16 contact inputs, and can provide 6 normally open (unmonitored) outputs and 4 digital inputs, which can flexibly replace existing modules or add new functions to the system. It supports high-speed data transmission, enabling precise control and monitoring of digital signals. The module adopts a compact and durable design, which is easy to integrate with existing systems, and can be set up and monitored through GE Multilin's EnerVista UR software, which provides convenient Viewpoint monitoring and maintenance tools.

Technical Parameters: The input voltage is 24VDC, the input voltage range is 0-24VDC, the input current is 5mA, and there are 6 input channels. The output voltage is 24VDC, the output voltage range is 0-24VDC, the output current is 250mA, and there are 6 output channels. The communication protocol is Modbus RTU, and the operating temperature is -40℃ to +70℃.

Working Principle: UR6DH collects digital signals from on-site equipment through its input channels, which may be the operating status, switching values of the equipment, etc. The module processes the collected signals, converts them into internal recognizable logic signals, and then outputs corresponding control signals through the output channels according to preset logic or instructions received through communication with external control systems (such as PLC) to control the operating status of other equipment, thereby realizing the monitoring and control of industrial processes. At the same time, it can interact with other equipment or systems through the Modbus RTU communication protocol to upload status information or receive control commands.

Application Fields: It is widely used in the field of industrial automation and can be used for production line control, robot control, etc. In the energy industry, it can be used for monitoring and control of power systems and substations. It is also suitable for building automation, such as control of air conditioning, lighting and security systems. In addition, it can be applied to industries such as petrochemicals, metallurgy, medical equipment, and transportation systems for related process control and equipment monitoring.

![]()