Description

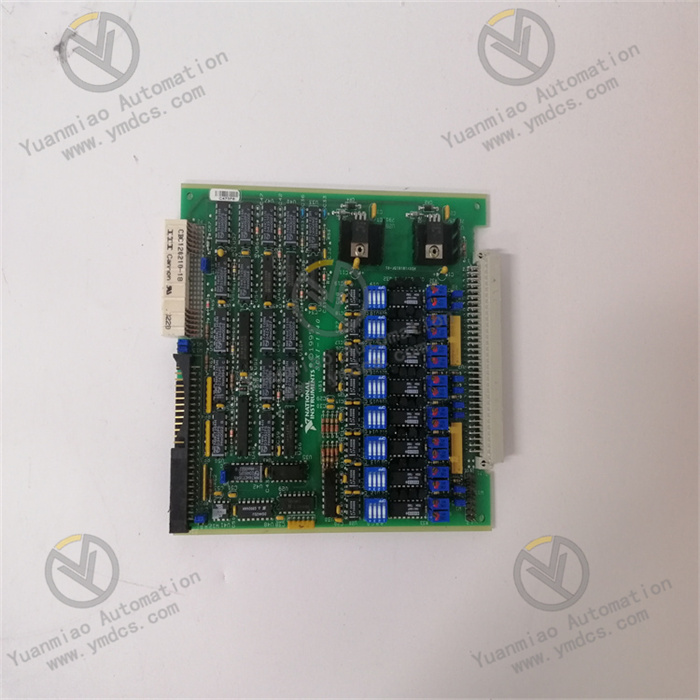

GE D20 EME

Overview

GE D20 EME is a compact embedded control module in the GE WESDAC D20 series, designed specifically for small and medium-sized industrial control systems. It mainly undertakes tasks such as logical control, data acquisition, and equipment linkage. As a lightweight product in this series, it inherits the core advantages of high reliability and real-time performance of the D20 series. Meanwhile, its compact size and simplified structure lower the threshold for system integration, making it suitable for industrial scenarios sensitive to space and cost.

This module integrates a processor, I/O interfaces, and communication functions into one. It can realize basic control functions without complex external expansion, and is compatible with other modules of the GE D20 series (such as power modules and communication adapters). It can also operate independently, providing stable control solutions for scenarios such as small and medium-sized production lines and equipment control cabinets, and is an ideal choice for connecting on-site equipment and simple control systems.

Technical Parameters

- Power Parameters: The working power supply is 24V DC, with an allowable voltage fluctuation range of ±15% and a rated power consumption of ≤15W. It can be directly connected to the DC power supply system in industrial sites, adapting to voltage fluctuation environments.

- Processor and Memory: Equipped with a 16-bit microprocessor with a main frequency of 80MHz, 8MB Flash memory, and 2MB RAM. It can store more than 1000 control logic instructions, meeting the program operation needs of small and medium-sized control scenarios.

- I/O Interfaces: Integrates 16 digital inputs (24V DC, compatible with dry/wet contacts) and 8 digital outputs (transistor output, maximum current 1A), and supports 4 analog inputs (0-10V DC or 4-20mA). Basic signal acquisition and control can be completed without additional modules.

- Communication Interfaces: Equipped with 1 RS-485 interface (supporting Modbus RTU protocol) and 1 Ethernet interface (10/100Mbps, supporting Modbus TCP/IP), enabling data interaction with PLCs, HMIs, or upper computers.

- Environmental Adaptability: The operating temperature range is -10℃-+60℃, and the storage temperature range is -40℃-+85℃; the relative humidity is 5%-95% (non-condensing); the protection level is IP20, suitable for installation in control cabinets to resist dust and slight moisture.

- Physical Specifications: The size is approximately 100mm×80mm×60mm (length × width × height), and the weight is about 200g. It supports DIN rail mounting, saving space in the control cabinet.

- Certification Standards: Complies with CE and UL 508 standards, passes industrial electromagnetic compatibility (EMC) tests, and adapts to the electromagnetic environment of industrial sites.

Functional Features

- Compact Integrated Design: Integrates the processor, I/O interfaces, and communication functions into one. It can realize basic control functions without external expansion, simplifying system wiring, reducing the space occupation of the control cabinet, and is especially suitable for the control needs of small and medium-sized equipment.

- Real-time Logic Control: The 80MHz main frequency processor supports fast logical operations with a control cycle of ≤10ms. It can respond to on-site signal changes in real time, realize functions such as sequential control and interlock protection of equipment, and ensure the continuity of the production process.

- Flexible Signal Adaptation: Compatible with digital and analog signal inputs, it can be directly connected to sensors, switches, transmitters, and other equipment. The output interface can drive executive components such as solenoid valves and small contactors, reducing signal conversion links and improving control accuracy.

- Simple Communication Interconnection: Realizes communication with upper computers or other control equipment through the Modbus protocol, supports data upload and remote control command reception, facilitating the construction of distributed monitoring systems and suitable for centralized management of small and medium-sized production lines.

- Reliable and Stable Operation: Equipped with overvoltage and overcurrent protection functions, the interface circuit adopts photoelectric isolation design, with strong anti-electromagnetic interference ability. It can work stably in the dusty and vibrating environment of industrial sites, with a mean time between failures (MTBF) of more than 100,000 hours.

- Convenient Debugging and Maintenance: Supports program download and parameter configuration through dedicated software. The surface of the module is equipped with LED indicators, which intuitively display the status of power supply, communication, and I/O, facilitating on-site personnel to quickly troubleshoot faults and shorten maintenance time.

Application Fields

- Small and Medium-sized Production Line Control: In production lines such as food packaging and small electronic assembly, it is used to control the start and stop of conveyors, the movement of manipulators, and equipment interlocking. It realizes the automatic connection of various processes through logical control. For example, in snack packaging lines, it coordinates the actions of feeding, sealing, and labeling equipment to improve production efficiency.

- Machine Tool Equipment Control: Used for auxiliary control of small and medium-sized machine tools such as CNC machine tools and milling machines. It collects signals such as spindle speed and tool position, controls the operation of cooling pumps and lubrication systems, and ensures the stability of the machine tool processing process. For example, in small lathes, the cooling system is automatically started and stopped according to the processing progress to extend the service life of tools.

- Heating, Ventilation, and Air Conditioning Systems: In air conditioning units of commercial buildings or industrial plants, it collects signals from temperature and humidity sensors, controls the opening of fans and valves, and realizes automatic adjustment of environmental parameters. For example, in office building air conditioning systems, it automatically switches between cooling/heating modes according to room temperature to save energy and reduce consumption.

- Small Water Treatment Equipment: In small filtration equipment and dosing devices of sewage treatment stations, it is used to control the operation of water pumps and solenoid valves, monitor water quality indicators (such as pH value), and automatically start and stop the treatment process through logical judgment to ensure stable effluent quality.

- Warehousing and Logistics Auxiliary Equipment: In small three-dimensional warehouses and conveying and sorting lines, it controls the actions of elevators and sorting mechanisms, and realizes accurate transfer of goods according to barcode recognition signals. For example, in small sorters of e-commerce warehouses, it controls the push rod action to distribute packages to corresponding areas.