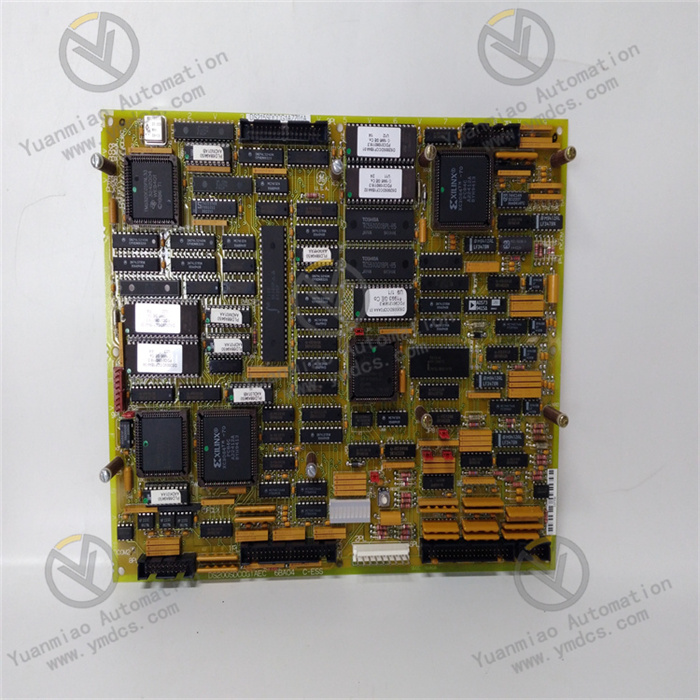

Description

Functional Features High-precision Control: By adopting advanced Digital Signal Processor (DSP) and control algorithms, it can achieve high-precision control of position, speed, and torque. It can precisely control the rotation angle, rotational speed, and output torque of the motor, meeting various high-precision motion control requirements. High Dynamic Performance: It has characteristics such as rapid response and high torque output, and is suitable for motion control scenarios with high speed, high acceleration, and high deceleration. It enables the equipment to start, stop, and change speed quickly during the movement process. Multifunctionality: It supports multiple control modes such as position, speed, and torque, and can also achieve multi-axis synchronous control. It can be flexibly selected and configured according to different application requirements, meeting the requirements of complex motion trajectory control. Rich Communication Interfaces: It provides various communication interfaces such as CANopen and EtherCAT, which is convenient for communication with the host computer and other devices. It is easy to integrate into various automation systems to achieve collaborative work between devices. High Reliability: It uses industrial-grade components, has good anti-interference performance, and is equipped with multiple protection functions such as overcurrent protection, overvoltage protection, and overheating protection. This can ensure the safety of the driver and the motor under abnormal conditions and guarantee the stable operation of the system. Easy to Use: It provides a user-friendly interface and configuration software, which is convenient for users to debug and maintain, reducing the usage threshold and improving work efficiency.

Technical Parameters Input Voltage: 188 - 528VAC, it can be directly powered by a grounded 110 to 480VAC, single-phase or three-phase, 50 to 60 Hz line. Output Current: 24A. Encoder Interface: It supports multiple types of encoders and can be connected to high-resolution encoders to obtain accurate motion feedback information. Ambient Temperature: -20°C - +50°C.

Application Scenarios

Machine Tool Industry: Such as CNC machine tools, machining centers, etc., it can achieve high-precision positioning and motion control of the tool and the worktable, improving the machining accuracy and efficiency.

Packaging Machinery: Such as packaging machines, filling machines, etc., it is used to control the conveying and positioning of packaging materials, as well as the movement of the filling head, etc., ensuring the packaging quality and production speed.

Printing Machinery: For example, printing machines, die-cutting machines, etc., it can precisely control the rotation of the printing cylinder, the feeding of the paper, and the position of the die-cutting tool, achieving high-quality printing and die-cutting processes.

Robots: Including industrial robots and collaborative robots, it provides precise drive control for the joint movement of the robot, enabling it to complete various complex actions and tasks.

Common Faults and Solutions 1. Overcurrent Fault Symptom: The driver displays an overcurrent alarm, and the motor may not start normally or stop suddenly during operation. Possible Causes: Short circuit of the motor cable; Short circuit inside the motor; Damage to the power module of the driver; Excessive load or jamming, resulting in an excessively large motor current. Solutions: Check whether the motor cable is damaged or short-circuited. If so, repair or replace the cable; Use an insulation resistance tester to check the insulation of the motor to determine whether the motor is short-circuited. If it is short-circuited, repair or replace the motor; Check the power module of the driver. If it is damaged, have it replaced by a professional; Check whether the load is jammed or overloaded, eliminate the load fault, and ensure that the motor can run normally. 2. Overvoltage Fault Symptom: The driver displays an overvoltage alarm, usually due to an excessively high power supply voltage or an excessive amount of energy generated during the motor's regenerative braking, resulting in an excessively high DC bus voltage. Possible Causes: The input power supply voltage is too high and exceeds the allowable range of the driver; The braking resistor is not connected or has an incorrect resistance value, resulting in the regenerative energy not being consumed in a timely manner; The braking unit is faulty. Solutions: Use a voltmeter to measure the input power supply voltage to confirm whether it is within the rated voltage range of the driver. If the voltage is too high, adjust the power supply or use a suitable voltage reduction device; Check whether the connection of the braking resistor is firm and whether the resistance value meets the requirements of the driver. If not, replace it with a suitable braking resistor; Check whether the braking unit is working properly. If it is faulty, repair or replace it. 3. Undervoltage Fault Symptom: The driver displays an undervoltage alarm, and the motor may not start normally or run unstably. Possible Causes: The input power supply voltage is too low; Poor contact or disconnection of the power supply line; Fault of the internal power module of the driver. Solutions: Measure the input power supply voltage to confirm whether it is within the allowable range of the driver. If the voltage is too low, check the power supply system, such as the transformer, lines, etc., to ensure the normal power supply voltage; Check whether the connection of the power supply line is firm, and whether there are any loose or disconnected phenomena. Repair or replace the faulty line; If the internal power module of the driver is faulty, have it repaired or replaced by a professional.

4. Encoder Fault Symptom: The driver displays an encoder alarm, and the motor may have a position deviation, be unable to be precisely controlled, or run abnormally. Possible Causes: Poor connection or damage to the encoder cable; Fault of the encoder itself; Loose installation or incorrect position of the encoder. Solutions: Check whether the connection of the encoder cable is firm, and whether there are any damaged or disconnected phenomena. Repair or replace the cable; Use professional testing equipment to check whether the encoder is working properly. If the encoder is damaged, replace it; Check whether the installation of the encoder is firm and whether the position is correct. If it is loose or the position is deviated, reinstall and adjust the encoder. 5. Overheating Fault Symptom: The driver displays an overheating alarm, possibly due to an excessively high internal temperature of the driver. Possible Causes: Poor ventilation of the driver, such as a damaged cooling fan or blocked ventilation openings; Excessively high ambient temperature; The driver operates under high load for a long time. Solutions: Check whether the cooling fan of the driver is operating normally. If the fan is damaged, replace it in a timely manner; Clean the ventilation openings of the driver to ensure good ventilation; Check whether the ambient temperature is too high. If it exceeds the allowable operating temperature range of the driver, take cooling measures, such as installing an air conditioner or strengthening ventilation; Reasonably adjust the working load of the driver to avoid long-term high-load operation. 6. Communication Fault Symptom: The driver cannot communicate normally with the host computer (such as PLC, motion controller), and may display a communication error alarm. Possible Causes: Poor connection or damage to the communication cable; Incorrect communication parameter settings; Fault of the communication interface of the driver or the host computer. Solutions: Check whether the connection of the communication cable is firm, and whether there are any damaged or disconnected phenomena. Repair or replace the cable; Confirm whether the communication parameter settings of the driver and the host computer are consistent, such as baud rate, data format, communication protocol, etc. If there are errors, adjust them; Check whether the communication interfaces of the driver and the host computer are working properly. You can try to replace the communication interface or use other devices for testing.

Main Products: Covering world-renowned brands: Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries. Service Advantages: ✅ Original imports with quality assurance ✅ Ample stock for rapid delivery ✅ Professional team for technical support ✅ Global logistics for worry-free coverage

Related Products

| SST SST-DN3-PCI-2 | TOSHIBA 2N2J2121-B02 |

| SST SST-DN3-PCU-1 | TOSHIBA 2N2J3026-A00 |

| SST SST-DN3-PCU-2 | TOSHIBA 2N2J3027-A00 |

| SST SST-DN4-104-2 | TOSHIBA 2N2K2187-B03 |

| SST SST-DN4-PCU | TOSHIBA MET23Z2K0260-1 |

| SST SST-PB3-CLX | TOSHIBA PLA33Z2J0212-3 |

| SST SST-5136-PFB-ISA | TOSHIBA PSR13Z2J0192-3 |

| SST SST-5136-PFB-PCI | TOSHIBA PWS73Z2J0192-4 |

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.