Description

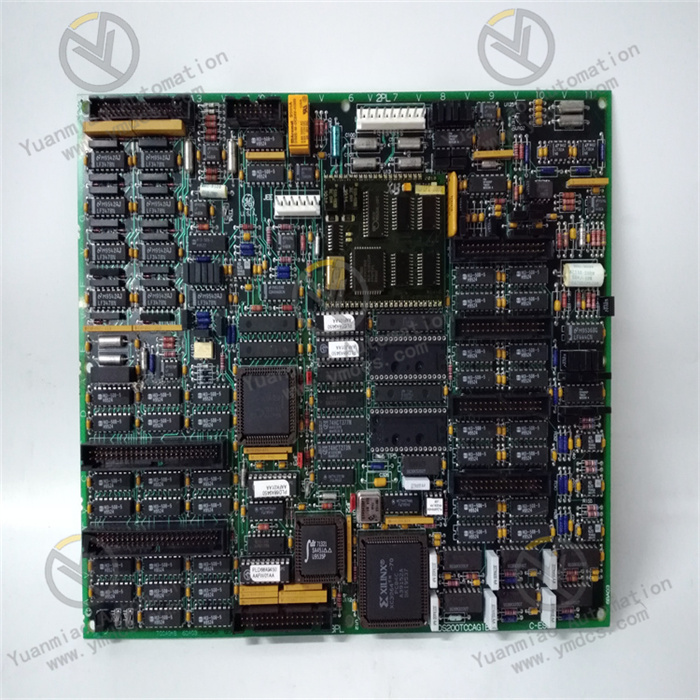

GE Multilin 369-HI-0-M-0-0-0-E

Overview

GE Multilin 369-HI-0-M-0-0-0-E is a high-performance motor management relay in the GE Multilin 369 series, specifically designed for comprehensive protection, monitoring, and control of medium and high-voltage motors. As a microprocessor-based intelligent device, it integrates advanced protection algorithms, precise measurement technologies, and flexible communication capabilities. It can respond in real-time to various faults during motor operation (such as overcurrent, overheating, and locked rotor) while providing abundant operating data, serving as a core equipment in the industrial field to ensure the safe and stable operation of motors.

This relay inherits the modular design of the 369 series, allowing flexible configuration of functions according to different motor types (such as asynchronous motors and synchronous motors) and application scenarios. It is widely applicable to key motor equipment in large industrial enterprises (such as fans, pumps, and compressors), providing a solid guarantee for the continuity of production processes.

Technical Parameters

- Power Supply Parameters: Supports a wide range of AC and DC power inputs, with AC 85-265V AC, DC 85-300V DC, frequency 50/60Hz, and rated power consumption ≤15W. It can adapt to voltage fluctuation environments in industrial sites and ensure stable operation.

- Protection Function Parameters:

- Current Protection: Covers phase overcurrent (instantaneous/definite time/inverse time), ground overcurrent, negative sequence overcurrent (for detecting motor imbalance or phase loss), and locked rotor protection (during start-up/operation phases). The current setting range is 0.1-100A (expandable via CT ratio), with a minimum action time ≤50ms.

- Temperature Protection: Supports RTD (Pt100, Cu100) or thermocouple (J, K type) inputs, capable of monitoring motor winding and bearing temperatures. The over-temperature trip value can be set to 50-200℃, and it has a temperature gradient monitoring function (to prevent rapid temperature rise).

- Voltage Protection: Includes phase overvoltage, undervoltage, and voltage imbalance protection. The voltage measurement range is 0-300V AC (line voltage), with a setting accuracy of ±1% and an action delay of 0.05-300s.

- Other Protections: Motor overload thermal simulation protection (based on I²t curve), start-up timeout protection (0.1-60s), underload protection (for detecting abnormalities such as pump idling), and overspeed/stall protection (requiring external speed signals).

- Measurement Parameters: Capable of measuring three-phase current, line voltage, active power, reactive power, power factor, motor speed (requiring a sensor), electrical energy (kWh), etc. The measurement accuracy is ±0.2% for current/voltage and ±0.5% for power, supporting harmonic analysis (up to the 15th harmonic).

- Communication Interfaces: Equipped with 1 10/100Base-TX Ethernet interface (supporting Modbus TCP/IP, IEC 61850) and 1 RS485 interface (supporting Modbus RTU), supporting dual-network redundancy. The maximum communication rate is 115200bps, enabling seamless integration into SCADA or industrial Ethernet systems.

- I/O Interfaces: Standard configuration includes 16 digital inputs (optically isolated, 24V DC) and 8 relay outputs (5A/250V AC), which can be expanded to 32 DIs and 16 DOs, supporting programmable logic control (PLC function).

- Environmental Adaptability: The operating temperature range is -40℃-+70℃, the storage temperature range is -40℃-+85℃, the relative humidity is 5%-95% (non-condensing), the protection grade is IP40 (front panel), and it has vibration resistance (10-500Hz, 1g) and shock resistance (25g, 11ms), adapting to harsh industrial environments.

- Physical Specifications: Adopts 19-inch rack mounting, with dimensions of 144mm×178mm×254mm (height × width × depth) and a weight of approximately 2.8kg. It supports a drawer-type structure for easy installation and maintenance.

- Certification Standards: Complies with standards such as IEC 60255, UL 508, CE, and SIL 2, and has passed ATEX and IECEx certifications, suitable for hazardous areas (such as chemical explosion-proof workshops).

Functional Features

- Multi-level Motor Protection: Integrates multi-dimensional protection functions including overcurrent, temperature, voltage, and mechanical faults (locked rotor, overspeed). It distinguishes between normal motor start-up and fault states through adaptive algorithms (such as avoiding misjudgment of overcurrent during start-up), ensuring the accuracy and rapidity of protection.

- Precise Thermal Simulation Protection: Built-in motor thermal model, which calculates winding temperature in real-time (considering ambient temperature, load rate, and cooling method). Compared with traditional RTD protection, it can better reflect the real thermal state of the motor, preventing insulation aging or burnout and extending motor life.

- Comprehensive Condition Monitoring: In addition to conventional current and voltage measurements, it can monitor motor vibration (requiring an external sensor), bearing temperature, operating efficiency, and other parameters. It predicts potential faults (such as bearing wear and winding insulation degradation) through trend analysis, enabling predictive maintenance.

- Flexible Communication and Integration: Supports protocols such as IEC 61850, Modbus TCP/IP, and DNP3.0, and can be connected to industrial Ethernet or SCADA systems to realize remote monitoring, parameter setting, and fault diagnosis. It has a built-in web server, allowing access to device status via a browser, simplifying the debugging process.

- Powerful Event Recording: Can store 1000 event records (with timestamp, accuracy ±1ms) and 20 fault waveforms (sampling rate 128 points/cycle), supporting data export via USB interface. It helps maintenance personnel trace the cause of faults and shorten downtime.

- Modular Expansion: Supports hot-swap expansion of I/O modules and communication modules. It can increase the number of DI/DO points or add special functions (such as synchronous motor excitation control) according to motor power and control requirements, adapting to different application scenarios.

Application Fields

- Industrial Production Drive Systems: In key equipment such as main motors of rolling mills in steel plants, stirring motors of reactors in chemical plants, and kiln fans in cement plants, it provides overload, short-circuit, and overheating protection to prevent production line shutdowns caused by motor faults. For example, a steel enterprise uses this relay to realize locked rotor protection for rolling mill motors, avoiding roll breakage accidents.

- Energy and Power Industry: Used in induced draft fans and forced draft fans of thermal power plants, auxiliary motors of water turbines in hydropower stations, ensuring the stable operation of auxiliary systems of generator sets; in substations, it protects cooling fan motors of large transformers to ensure normal heat dissipation of transformers.

- Municipal and Infrastructure: In sewage pump motors of urban sewage treatment plants and booster pump motors of waterworks, it monitors motor operating status, detects pump idling (such as impeller blockage) through underload protection, and alarms and shuts down in time to avoid equipment damage.

- Petrochemical Field: Suitable for explosion-proof occasions such as compressor motors and oil transfer pump motors in refineries. With SIL 2 certification and explosion-proof certification, it provides reliable protection in flammable environments to prevent safety accidents caused by motor sparks.

- Mining and Metallurgy: In hoist motors of coal mines and crusher motors of metal mines, it copes with complex working conditions such as heavy-load start-up and frequent forward and reverse rotation. It avoids overload through inverse time overcurrent protection and monitors bearing temperature to prevent overheating, ensuring the continuous progress of mining operations.