Description

I. Model Decomposition and Meaning

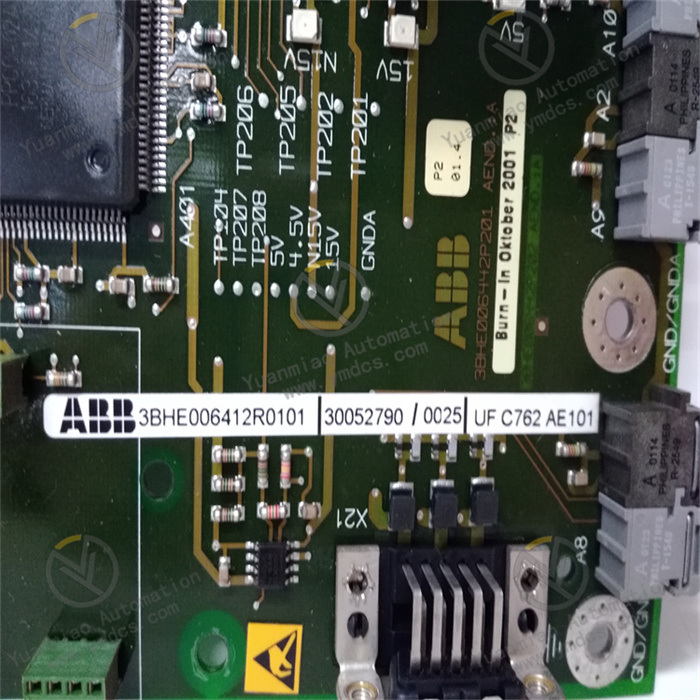

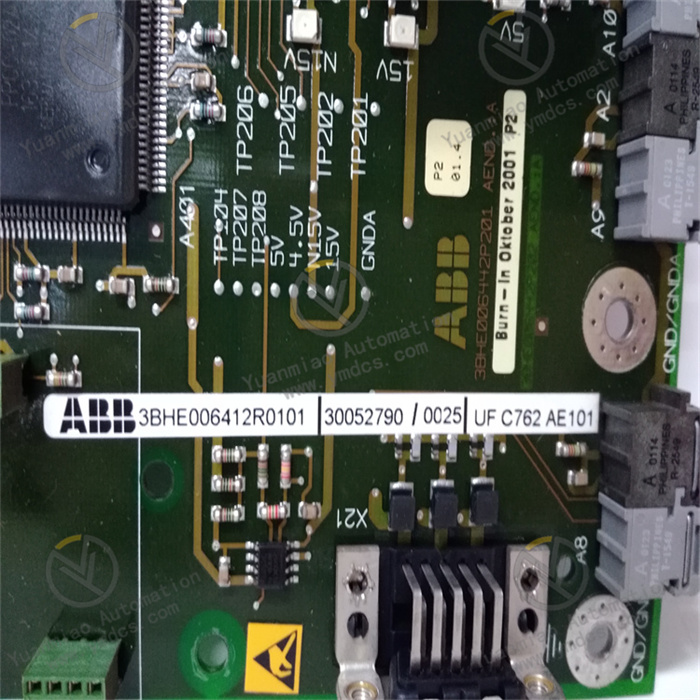

UFC762AE101

- UFC: May represent the product series or device type. In ABB's industrial automation products, "UFC" is commonly found in frequency converter modules or control units (such as the control board of the ACS800 series frequency converters).

- 762: May indicate the product version or specification (e.g., voltage level, power range, etc.).

- AE101: May represent the configuration or function code (e.g., input/output type, communication interface, etc.).

3BHE006412R0101

- 3BHE: A standard prefix for ABB products, used to identify low-voltage products or automation system components (such as PLC modules, drive modules, etc.).

- 006412: May be the unique identification code of the product (similar to a part number).

- R0101: Usually indicates the version number, where "R" stands for "Revision" (revision), and "0101" may represent the specific version iteration (e.g., hardware version, software version).

II. Technical Parameters

Input Signals

- Voltage: 0-20mV, 0-1V (input impedance ≥5MΩ), 0-5V (input impedance ≥100KΩ).

- Current: 4-20mA, 0-20mA (input resistance ≤250Ω), 0-10mA (input resistance ≤500Ω).

Output Signals

- Analog Output: PID control output voltage: 0-5V, 1-5V (load resistance ≥200KΩ); current: 0-10mA (load resistance ≤1000Ω), 4-20mA, 0-20mA (load resistance ≤500Ω).

- Relay Output: Contact switch output, contact rating: 220VAC/2A or 24VDC/2A.

- SSR Drive: Drive voltage: 12VDC/30mA (used to drive SSR solid-state relays).

- Communication Transmit Output: 4-20mA, 1-5V, RS485 communication.

Accuracy

±0.2% F.S ±1 digit, with automatic compensation for temperature drift and time drift.

Current Output Load Capacity

0-600Ω or 0-250Ω.

Measurement and Control Cycle

0.5s.

Power Distribution Output

DC24±1V (25mA).

Isolator Isolation Voltage

Input-output: 1500V; input-power supply/output-power supply: 1000V.

Operating Environment

- Temperature: 0-50°C;

- Relative humidity: ≤80% RH.

Power Supply

Switching power supply: 100-240VAC (50Hz/60Hz), 24VDC/AC±2V, power consumption ≤2W.

Dimensions

100×112×45 (22.5) mm.

Installation Method

DIN35 rail mounting.

III. Functional Features

- Diverse Control Functions: As a universal controller, it supports multiple control modes such as PID control, fuzzy control, and adaptive control, which can be flexibly selected according to different industrial control requirements to achieve precise control of various industrial processes.

- Rich Inputs and Outputs: Input signals support analog (0-10V, 4-20mA) and digital (ON/OFF), capable of receiving signals from various sensors to accurately perceive parameter changes in industrial processes. Output signals also support analog (0-10V, 4-20mA) and digital (ON/OFF), enabling precise control of actuators such as motor speed and valve opening.

- High Control Accuracy: Control accuracy up to ±0.1% FS, meeting the requirements of industrial applications with high precision needs to ensure the stability of industrial processes and the consistency of product quality.

- Strong Communication Capability: Supports multiple industrial communication protocols such as RS485, Modbus, and Profibus, facilitating data exchange and networked control with other devices. It can be easily integrated into complex industrial automation control systems to achieve collaborative operation between devices.

- High Reliability: Adopts high-quality components and advanced design processes, with good anti-interference capabilities, capable of stable operation in harsh industrial environments. It adapts to a working temperature range of -10°C to +55°C, reducing equipment failures caused by environmental factors and improving system reliability and stability.

- Flexible Installation: With dimensions of 144mm×144mm×102mm, it supports both panel mounting and wall mounting. Users can choose suitable installation methods according to actual installation space and system layout, enabling quick and convenient integration into existing equipment or systems.

IV. Application Scenarios

Industrial Automation Control Modules

- Examples: Communication modules, IO modules, or drive control units for PLC (Programmable Logic Controllers).

- Application scenarios: Factory automation production lines, process control (e.g., chemical, power, metallurgical industries, etc.).

Frequency Converter-Related Components

- Examples: Control boards for the ACS800 series frequency converters (such as the UFC762 series), used for motor speed regulation and control.

- Application scenarios: Motor drive systems for fans, pumps, compressors, etc.

Robot Accessories

- In ABB's robot product line, some control modules or sensor modules may also use similar numbering rules.

- Application scenarios: Industrial robot body control, motion trajectory planning, etc.

V. General Operation Guide for ABB UFC762AE101 3BHE006412R0101

Password Entry

- Step 1: Press and hold the "Target Flame Selection" and "Background Flame Selection" buttons simultaneously, then use the up button to drive the LED until LED number (5) (password) lights up. If you exceed the desired position, use the down button to correct it.

- Step 2: Press and hold the "Target Flame Selection" and "Background Flame Selection" buttons again. At this point, the Ready LED will flash, the Flame On/Off LED will turn off, and the Flame Learning LED and Background Learning LED will flash.

Learning/Storing Target Flame

Press the Target Flame Selection button, the Learning Target Flame LED will light up, and the flame relay output will be energized, allowing the flame signal to be sent to the relevant system during commissioning.

Routine Operations

- Parameter Setting: Set input signal types (e.g., voltage, current, etc.), output signal types, control parameters (e.g., PID parameters, etc.) through the control panel or related software according to specific application requirements.

- Monitoring and Adjustment: Monitor the device's operating status in real time, including input/output signal values, control process feedback, etc. Adjust control parameters in a timely manner based on actual conditions to optimize control performance.

Communication Setup

- Connecting Communication Cables: Correctly connect the device to other systems or devices according to the selected communication protocol (e.g., RS485, Modbus, etc.) to ensure stable communication lines.

- Configuring Communication Parameters: Set communication-related parameters (e.g., communication address, baud rate, data bits, parity bit, etc.) in the device's settings interface to match those of the connected devices, enabling normal data exchange and communication.

Maintenance and Care

- Regular Inspections: Regularly check the device's appearance for damage, overheating signs, loose connection cables, etc. Clean dust and debris from the device surface to ensure good heat dissipation.