Description

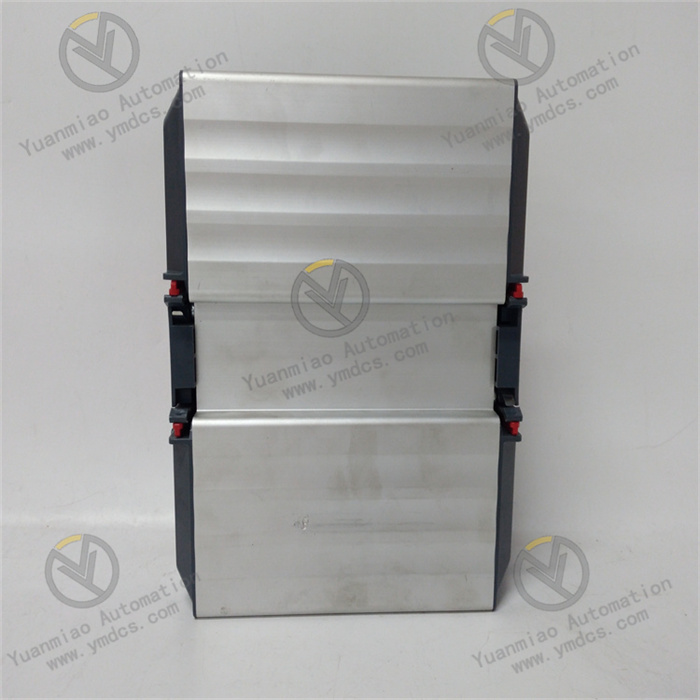

MOOG D136-001-007

The MOOG D136-001-007 is a high-performance servo controller. Its working principle involves receiving external input signals, which can be feedback signals from sensors (such as position and speed detected by sensors) or control command signals sent by a host computer. The controller then processes and analyzes these signals based on pre-set internal control algorithms and logic, interacts with the servo motor through a communication interface, and outputs corresponding control signals to the servo motor to precisely control its movement. This achieves accurate control of the mechanical equipment's position, speed, and force, meeting the high-precision motion control requirements of different application scenarios.

Features

- High Precision: Offers extremely high position and speed control accuracy, with a position accuracy of up to ±0.01°, suitable for precision motion control needs.

- High Response Speed: Features fast response (response time < 1ms), enabling quick tracking of target positions and speeds.

- High Reliability: Adopts an industrial-grade design with excellent stability and reliability, suitable for harsh industrial environments.

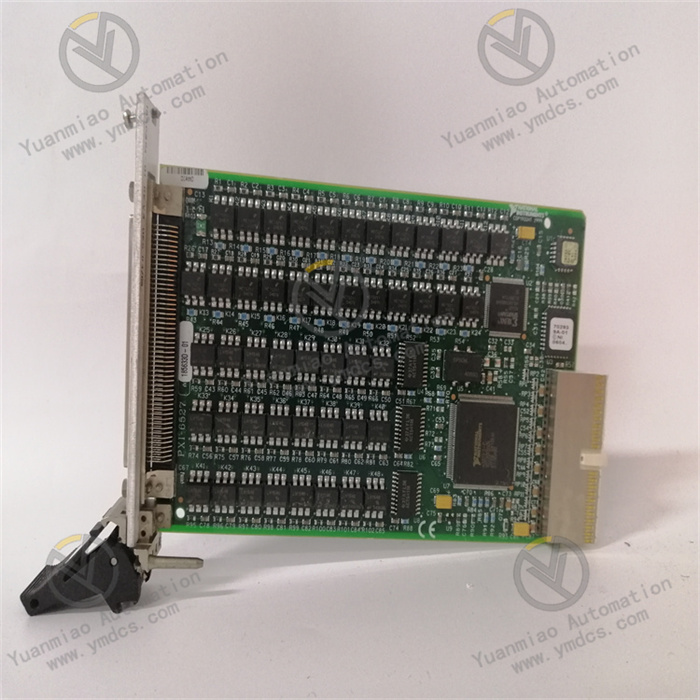

- Modular Design: Easy to configure and maintain.

- Multifunctionality: Integrates multiple control functions, such as position control, speed control, and force control. It also integrates PLC functions to achieve complex control logic.

Parameters

- Power Supply Voltage: 24–48VDC

- Power Consumption: 100W

- Control Modes: Current, speed, position

- Rated Current: 10A

- Rated Speed: 3000RPM

- Communication Interfaces: Supports multiple communication protocols, such as CANopen and EtherCAT.

- Dimensions: 220mm × 160mm × 41mm

- Weight: 1.3kg

Functions

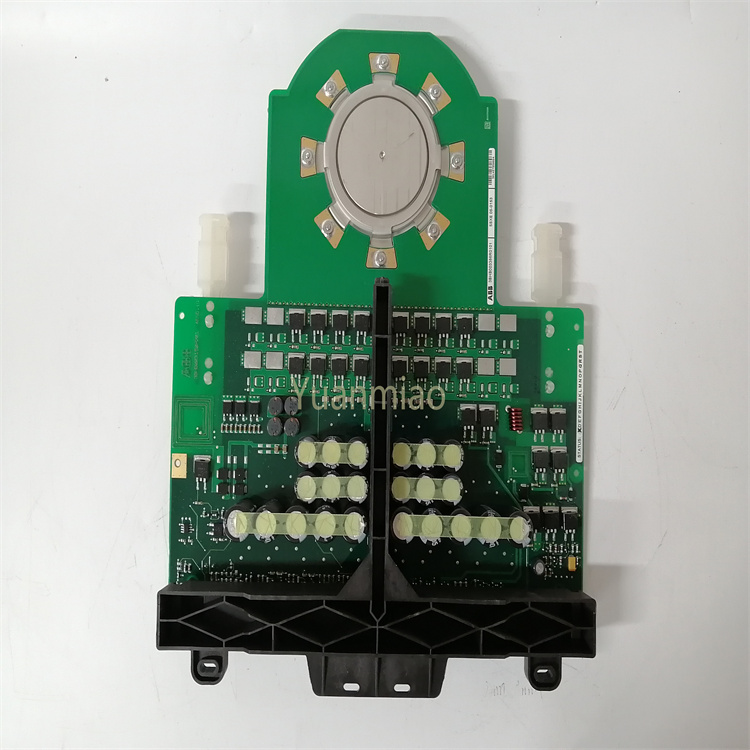

- Control Functions: Precisely controls the position, speed, and force of servo motors, capable of simultaneously controlling two servo motors.

- Signal Acquisition and Control: Equipped with high-resolution analog input/output interfaces for precise signal acquisition and control; supports various position sensors, such as encoders and resolvers.

Application Fields

- Industrial Automation: Used in robots, automated production lines, packaging machinery, etc.

- Aerospace: Suitable for flight control systems, satellite attitude control, etc.

- Semiconductor Equipment: Used for precision motion control.

- Medical Equipment: Achieves precise control of medical devices.

- Automotive Manufacturing: Applied in automotive assembly, welding, painting, and other processes.

- Electronic Manufacturing: Such as PCB manufacturing and electronic component assembly.

- Machine Tool Industry: Used in CNC machine tools and numerical control machining centers.

Common Faults and Solutions

1. No Output or Abnormal Signals

- Possible Causes:

- Power supply failure (unstable voltage, loose wiring, blown fuse).

- Incorrect input signals (mismatched signal types, wiring errors, signal source faults).

- Damaged internal electronic components (e.g., amplifiers, circuit board faults).

- Mechanical parts jamming (valve core sticking, motor stalling).

- Solutions:

- Check if the power supply voltage matches the rated value, ensure wiring is secure, and replace the fuse.

- Use a multimeter or oscilloscope to test if the input signals are normal, and verify signal types (e.g., analog, digital) and wiring diagrams.

- Investigate whether mechanical parts move flexibly and manually test the actuators (e.g., motors, cylinders) for jamming.

- If a circuit board fault is suspected, try replacing the backup module or contact professional maintenance personnel.

2. Abnormal Vibration or Noise

- Possible Causes:

- Loose mechanical installation (components loose, misaligned couplings).

- Air in the hydraulic system (air entering the servo valve or cylinder).

- Improper servo parameter settings (excessive gain, unreasonable filter parameters).

- Contaminated oil or abnormal viscosity (common issue in hydraulic servo valves).

- Solutions:

- Check mechanical connections such as mounting bolts and couplings, and re-calibrate alignment.

- Vent the hydraulic system and inspect pipeline tightness.

- Adjust servo controller parameters (e.g., reduce gain, optimize PID parameters) and set filter values according to the manual.

- Replace or filter the hydraulic oil and check if the oil viscosity and contamination level meet requirements.

3. Overheating or High Temperature

- Possible Causes:

- Poor heat dissipation (fan failure, blocked cooling vents, high ambient temperature).

- Excessive load or long-term full-load operation.

- Internal component short circuits (e.g., power devices, aging capacitors).

- Solutions:

- Clean the equipment's cooling vents, check if the fan is operating normally, and ensure good ventilation.

- Reduce the load or add cooling devices (e.g., heat sinks, air conditioners).

- Power off to test component resistance values and replace aging or damaged capacitors and power modules.

4. Reduced Control Accuracy or Drift

- Possible Causes:

- Sensor faults (encoder, feedback potentiometer failure, or signal interference).

- Wear or contamination of the servo valve (valve core wear in the hydraulic system causing leakage).

- Parameter drift (component aging after long-term operation, such as changes in resistor and capacitor values).

- Excessive mechanical clearance (gearbox, lead screw wear).

- Solutions:

- Test if sensor signals are stable and eliminate electromagnetic interference (e.g., use shielded cables, grounding).

- Clean or replace the servo valve and filter the hydraulic oil.

- Re-calibrate parameters and adjust zero points and gains (refer to the MOOG debugging manual).

- Inspect mechanical transmission components, replace worn parts, and adjust clearances.

5. Alarm Code Prompt

- Possible Causes:

- Built-in diagnostic functions triggering alarms (e.g., overload, overvoltage, communication faults).

- Software configuration errors (e.g., mismatched communication protocols, address conflicts).

- Solutions:

- Refer to the equipment manual to locate specific fault points based on alarm codes (e.g., E01, F03, etc.).

- Check communication parameter settings (baud rate, data bits, slave address) and test communication line connectivity.

- Restart the device or restore factory settings (note: back up configuration data).