Description

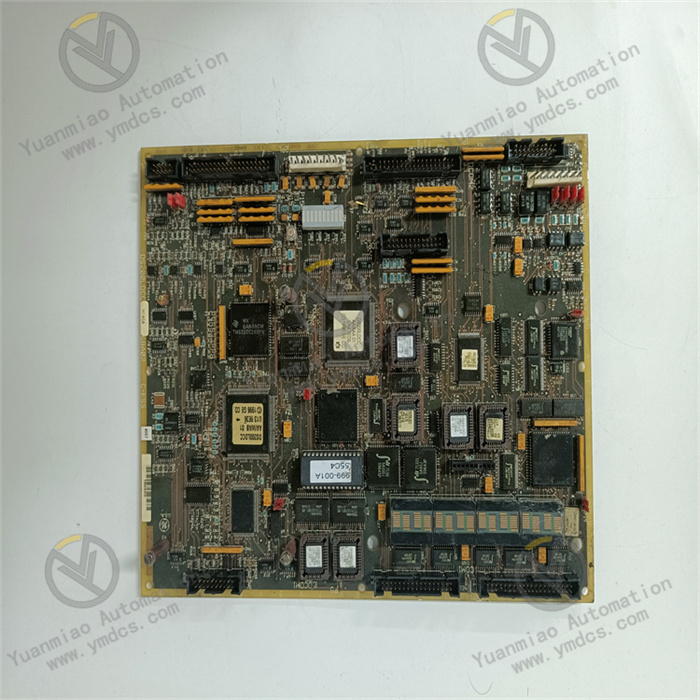

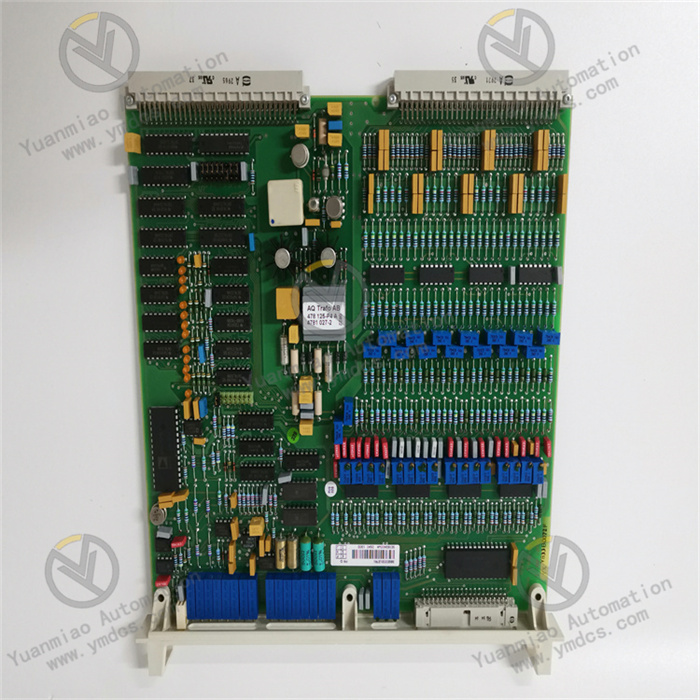

ABB DAPI100 3AST000929R109

ABB DAPI100 3AST000929R109 is an Ethernet communication interface module, whose core positioning is to achieve high-speed data transmission and seamless communication interconnection between devices in industrial automation systems. It undertakes core tasks such as data transceiving, protocol conversion, communication status monitoring, and transmission of equipment linkage control signals, serving as a key communication hub connecting distributed control systems (DCS), industrial controllers and various terminal devices. This module is widely used in industrial scenarios with stringent requirements for communication stability and real-time performance, including industrial automation production lines, power system monitoring and control, manufacturing process management, crane control systems, petrochemical process control, and building automation. Adopting an industrial-grade enhanced design, it supports multiple communication protocols and flexible integration methods, and can be accurately matched with mainstream control systems such as ABB Advant OCS and Advant Controller 450, providing stable and reliable communication support for the efficient coordinated operation of industrial automation systems.

Relying on a stable Ethernet communication architecture, multi-protocol compatibility, and industrial-grade anti-interference design, the ABB DAPI100 3AST000929R109 module enables seamless data interaction between different devices and systems. While improving the communication efficiency of industrial automation systems, it enhances the integration flexibility and operational reliability of the system, reduces production downtime caused by communication interruptions or data transmission errors, lowers operation and maintenance costs, and serves as a key core component in industrial automation communication networks.

1. Product Features

1.1 High-Speed Ethernet Communication for Efficient and Stable Data Transmission

1.2 Multi-Protocol Compatibility for Flexible Integration and Adaptation

1.3 Comprehensive Status Monitoring for Convenient Diagnosis and Maintenance

1.4 Industrial-Grade Anti-Interference Design for Excellent Environmental Adaptability

1.5 Easy Integration and Installation with Simple Operation and Configuration

1.6 Reliable and Durable Structure for High Operational Safety

2. Technical Parameters

2.1 Basic Parameters

- Model: ABB DAPI100 3AST000929R109

- Product Type: Ethernet Communication Interface Module

- Brand: ABB

- Product Series: Advant OCS Control System Communication Module Series

- Application Fields: Industrial automation production lines, power system monitoring and control, manufacturing process management, crane control systems, petrochemical process control, building automation

- Compatible Systems: ABB Advant OCS distributed control system, ABB Advant Controller 450 (Version 2.3), and other mainstream industrial automation systems

- Communication Medium: Ethernet MVI

- Mounting Method: Built-in cabinet installation

- Net Weight: Approximately 0.182kg (182 grams)

- Warranty Period: 12 months

- RoHS Compliance: Compliant with relevant environmental protection standards

- WEEE Category: Category 5 (small equipment with external dimensions not exceeding 50 cm in all aspects)

2.2 Electrical Parameters

- Supply Voltage: 24V DC±10% (industrial standard power supply)

- Power Consumption: Typical value ≤5W (full load operation), maximum value ≤8W

- Communication Protocols: Supports multiple industrial communication protocols including TCP/IP

- Communication Interface: Ethernet interface (standard RJ45 interface)

- Data Transmission Rate: 10/100Mbps adaptive

- Protection Functions: Overvoltage protection, overcurrent protection

- Isolation Level: Electrical isolation between communication interface and power supply terminal, rated isolation voltage ≥250V AC (continuous)

- ESD Protection: ±2kV contact discharge, ±8kV air discharge

2.3 Mechanical and Environmental Parameters

- Dimensions (W×H×D): 234mm×27mm×112.5mm

- Operating Temperature: -25℃~+70℃

- Storage Temperature: -40℃~+85℃

- Relative Humidity: 5%~95%RH (no condensation)

- Electromagnetic Interference Resistance: Complies with EN 55011 Group 1 Class A and EN 61000-4 series anti-interference standards

- Vibration Resistance: Complies with IEC 60068-2-6 standard, 10-150Hz, acceleration 5g

- Impact Resistance: Complies with IEC 60068-2-27 standard, acceleration 15g, duration 11ms

- Protection Rating: IP20 (front-end protection after installation)

- Housing Material: Flame-retardant engineering plastic + metal shielding cover

3. Working Principle

4. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting and Solutions |

|---|---|---|

| No response when the module is powered on, and the status indicator light does not turn on | Abnormal power supply (power failure, voltage out of the range of 24V DC±10%), loose wiring of power terminals or reversed positive and negative poles, damaged or broken power connection cables, internal power circuit failure of the module | Use a multimeter to measure the voltage of the power supply terminals to confirm that the voltage meets the requirement of 24V DC±10%; check whether the wiring of the power terminals is firm, verify that the positive and negative poles are connected correctly, and re-tighten the wiring; check whether the power connection cables are damaged or broken, and replace them with high-quality power connection cables; if the above inspections are all normal but there is still no response, there may be a fault in the internal power circuit of the module, and it is necessary to contact ABB authorized after-sales service for maintenance or module replacement. |

| Failure to establish an Ethernet communication connection | Incorrect communication parameter configuration (mismatched IP address, subnet mask, gateway), damaged or loosely connected Ethernet cables, failure of network equipment such as switches, wrong communication protocol selection, communication interface failure of the module | Verify the communication parameters of the module and the upper control system to ensure that the IP address, subnet mask, and gateway configurations are consistent, reconfigure and save the parameters; check whether the Ethernet cable connection is firm, and replace it with a intact Ethernet cable for testing; check the operating status of intermediate network equipment such as switches to ensure that the network equipment is working normally; confirm that the selected communication protocol is correct, and re-select an appropriate communication protocol according to system requirements; if the above inspections are all normal but the connection still cannot be established, there may be a fault in the module's communication interface, and contact after-sales service for maintenance or module replacement. |

| Interrupted data transmission or severe packet loss | Poor quality of Ethernet cables or transmission distance exceeding the limit, excessive electromagnetic interference in industrial sites, excessive network load, outdated module firmware version | Replace with high-quality Ethernet cables and ensure that the transmission distance complies with industrial Ethernet specifications; check whether the module installation location is close to strong interference sources such as frequency converters and high-voltage cables, install a metal shielding cover or optimize the line layout to enhance the cable shielding effect; troubleshoot the network load, reduce unnecessary data transmission tasks, and optimize the network topology; check the module firmware version, and if the version is outdated, contact ABB authorized after-sales service for firmware upgrade. |

| The module frequently triggers fault alarms, and communication is unstable | Excessive fluctuations in supply voltage, poor grounding of the module, unreasonable communication parameter configuration, internal circuit failure of the module | Check whether the supply voltage has excessive fluctuations; if so, install a voltage stabilizer at the front end; check whether the module grounding is reliable, re-tighten the grounding terminal to ensure that the grounding resistance meets the requirements; re-verify and optimize the communication parameter configuration, reduce the data transmission rate or adjust the communication timeout time; if the above measures are ineffective, there may be a fault in the module's internal circuit, and contact after-sales service for maintenance or module replacement. |

| Data transmission errors and abnormal equipment control | Mismatched communication protocols, incorrect data format configuration, abnormal signal interaction between the module and equipment, data distortion caused by external interference | Confirm that the communication protocols of the module and the terminal equipment are consistent, and reconfigure the communication protocol parameters; check whether the data format configuration is correct to ensure that the data parsing rules of the sending end and the receiving end are consistent; disconnect the connection between the module and the terminal equipment, test the equipment receiving function with a standard signal source to rule out the equipment's own faults; check the electromagnetic interference of the installation environment and take shielding measures to reduce interference and ensure accurate data transmission. |