Description

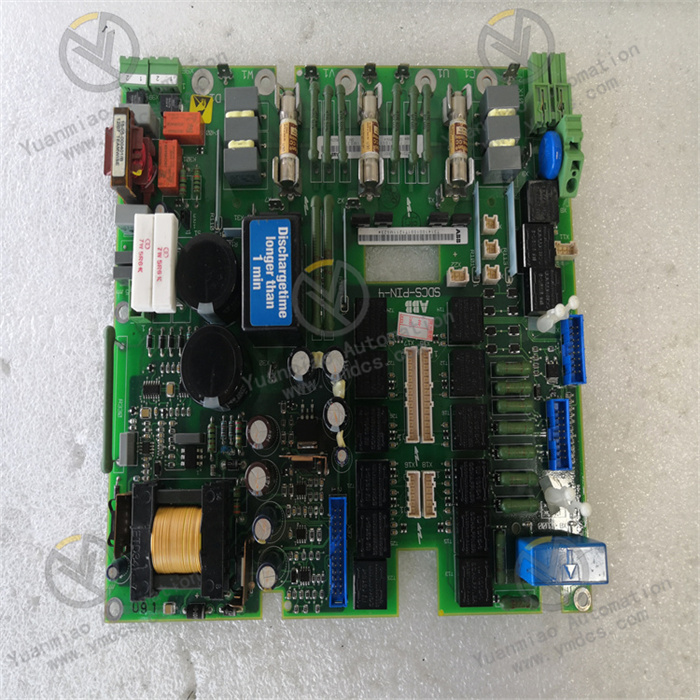

ABB ACS880-01-040A-5 3AUA0000090438

ABB ACS880-01-040A-5 (Order Number: 3AUA0000090438) is a compact wall-mounted AC variable frequency drive, specially designed for motor speed control in industrial scenarios. With a rated power of 22kW and a rated input current of 40A, this drive is compatible with 380-500V three-phase AC power supply. Boasting an integrated design, rich control functions and excellent environmental adaptability, it can precisely control various industrial motors such as fans, pumps, conveyors and mixers. Widely applied in industries including petrochemicals, mining and metallurgy, water treatment, food and beverage, it provides an efficient and stable speed control solution for production processes. Meanwhile, it features energy consumption optimization and fault early warning capabilities, facilitating the intelligent operation of industrial equipment.

1. Product Attributes

As a basic general-purpose drive in the ACS880 series, it is positioned as a high-reliability industrial-grade speed control unit. Different from special-purpose drives, it focuses on multi-scenario adaptability and convenient operation and maintenance requirements. The specific basic information is as follows:

- Product Model: ACS880-01-040A-5 (Order Number: 3AUA0000090438, EAN Code: 6438177557609)

- Product Type: Three-phase AC general-purpose variable frequency drive, compact wall-mounted design, frame size R4

- Core Purpose: Realize precise speed regulation, torque control and start-stop management of industrial motors with power of 22kW or below; reduce energy consumption by optimizing motor operation parameters; and ensure the safe operation of motors and equipment with comprehensive fault protection functions

- Basic Information: Customized production mode, minimum order quantity of 1 unit, net weight of a single unit is 18.6kg (41.006lb)

2. Technical Specifications

2.1 Electrical Performance Parameters

- Power Supply and Frequency: Compatible with 380-500V three-phase AC input power supply, supporting wide frequency input of 47.5-63Hz to adapt to power grid standards in different regions; the output frequency range covers 0-500Hz, meeting the control requirements of high and low speed motors

- Current and Power: Rated input current 40A, rated output power 22kW; the output current is 34A under heavy-duty conditions (for long-term stable operation), and it can adapt to higher load fluctuations under light-duty conditions with a certain overload capacity

- Control Performance: Built-in standard PID control algorithm, supporting seamless switching among three control modes (speed, torque and voltage) with high speed regulation accuracy, which can accurately respond to process parameter adjustments; equipped with harmonic filtering reactor to effectively suppress grid harmonic interference and improve operation stability

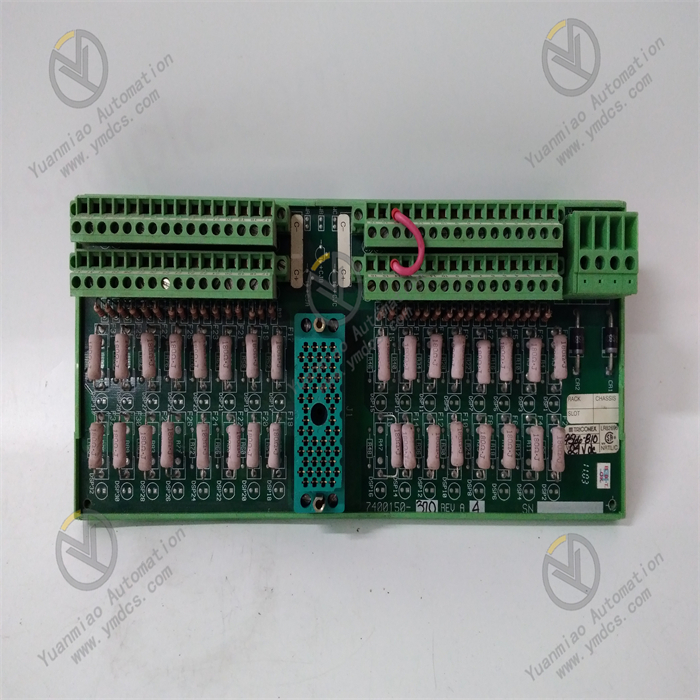

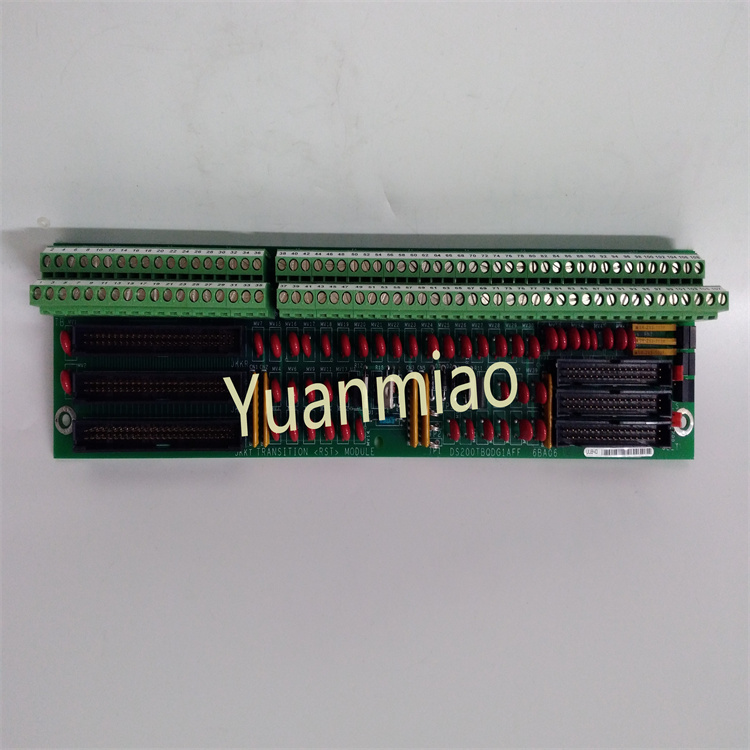

- Interface Configuration: Equipped with 2 analog input channels, 2 analog output channels, 6 digital input channels and 2 digital output channels to meet the needs of multi-signal interaction; communication interfaces include 1 RS-485 port, 1 USB port and 4 universal interfaces, supporting multiple industrial communication protocols such as Modbus, CAN, DeviceNet, Profinet IO and Ethernet/IP, which can be seamlessly integrated into distributed control systems

2.2 Physical and Protection Specifications

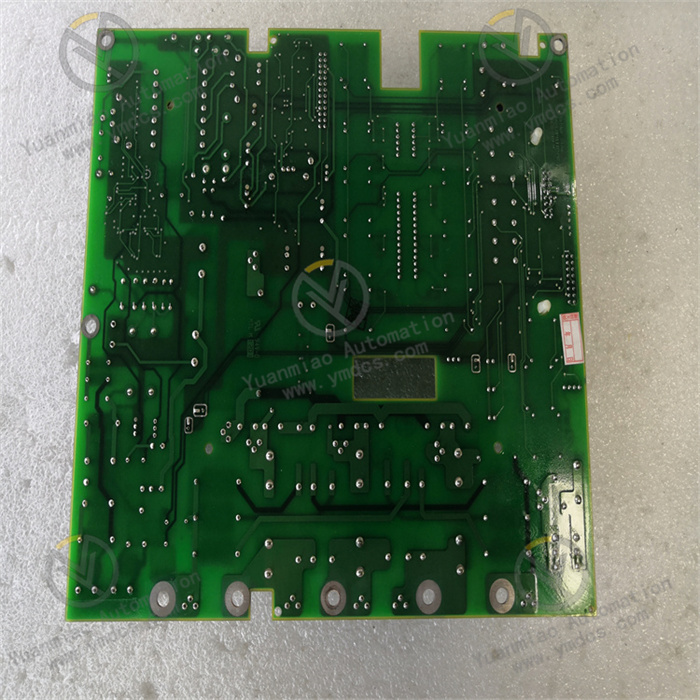

- Dimensions: Net dimensions are 274mm (length) × 580mm (height) × 203mm (width), and packaging dimensions are 691mm × 329mm × 290mm. The compact size saves installation space and is suitable for wall-mounted deployment on walls and beside cabinets

- Protection Rating: IP21 (NEMA Type 1) protection rating, with dustproof and vertical water droplet proof capabilities, suitable for non-outdoor installation environments such as industrial control rooms and workshop sites, which can effectively resist slight dust and water vapor erosion

- Installation Method: Standard wall-mounted installation. The mounting surface must have sufficient load-bearing capacity, and sufficient ventilation space must be reserved to avoid dense stacking with other equipment and ensure smooth heat dissipation; the R4 frame size design enables stable fixation without additional reinforcement

2.3 Environmental and Operational Capabilities

- Temperature Range: Operating temperature ranges from -10℃ to +40℃ (without derating). Derated operation can be performed appropriately as the temperature rises when exceeding 40℃. The storage temperature ranges from -40℃ to +70℃, adapting to the temperature environment of most industrial scenarios

- Humidity and Altitude: Relative humidity 5%-95% (non-condensing) to avoid circuit short circuit caused by humid environment; maximum applicable altitude is 4000m, and derating can ensure stable operation in high-altitude areas

- Other Features: The operating noise is 64dB(A), and the low-noise design is suitable for indoor installation scenarios; built-in 2 CR2032 lithium batteries (3V/220mAh) for parameter backup to ensure that configurations are not lost after power failure

3. Compatible Systems and Hardware Combinations

- Compatible Motors: Suitable for three-phase asynchronous motors with power of 22kW or below, compatible with ordinary asynchronous motors and high-efficiency energy-saving motors. The rated current of the motor shall not exceed the rated output current of the drive to ensure the normal operation of speed regulation and protection functions

- Compatible Control Systems: Can be seamlessly integrated into ABB distributed control systems and third-party industrial automation systems, realizing remote control, parameter debugging and data collection through supported multiple communication protocols, and can also be manually operated through the local control panel

- Supporting Components: Can be matched with optional accessories such as braking choppers, EMC filters, I/O expansion modules and functional safety modules to expand functions for complex scenarios; special variable frequency drive cables (symmetrical shielded VFD cables) are recommended to reduce bearing current and insulation loss and improve electromagnetic compatibility

4. Product Features

4.1 Integrated Design for Convenient Operation and Maintenance

4.2 Multi-scenario Adaptability with Precise Control

4.3 Safe and Reliable with Comprehensive Protection

5. Application Scenarios and Safe Operation Precautions

5.1 Application Scenarios

5.2 Safe Operation and Maintenance Specifications

- Installation, wiring and maintenance work must be performed by qualified electricians. Before operation, all power supplies must be disconnected, and the Lockout-Tagout (LOTO) procedure must be implemented. After disconnecting the power supply, wait for 5 minutes to allow the intermediate circuit capacitor to discharge completely, and confirm that the voltage is close to 0V with a multimeter (impedance ≥1MΩ) before operation to avoid electric shock hazards.

- It is strictly prohibited to connect the drive to a power supply exceeding the rated voltage to avoid activating the braking chopper, which may cause resistor overload or rapid motor operation; insulation or withstand voltage tests on the drive are prohibited to prevent damage to internal circuits.

- During installation, ensure that the wall-mounted surface is firm and reserve sufficient ventilation space to avoid dust accumulation and high-temperature environment; symmetrical shielded VFD cables are recommended for motor cables, with both ends grounded to reduce electromagnetic interference and bearing wear.

- If the drive has not been powered on for more than 1 year, the DC link capacitor must be reconditioned first, which can be performed with reference to the official hardware manual or by contacting ABB technical support; regularly clean dust on the equipment surface, check the tightness of wiring terminals and the insulation status of cables to ensure the normal operation of the equipment.