Description

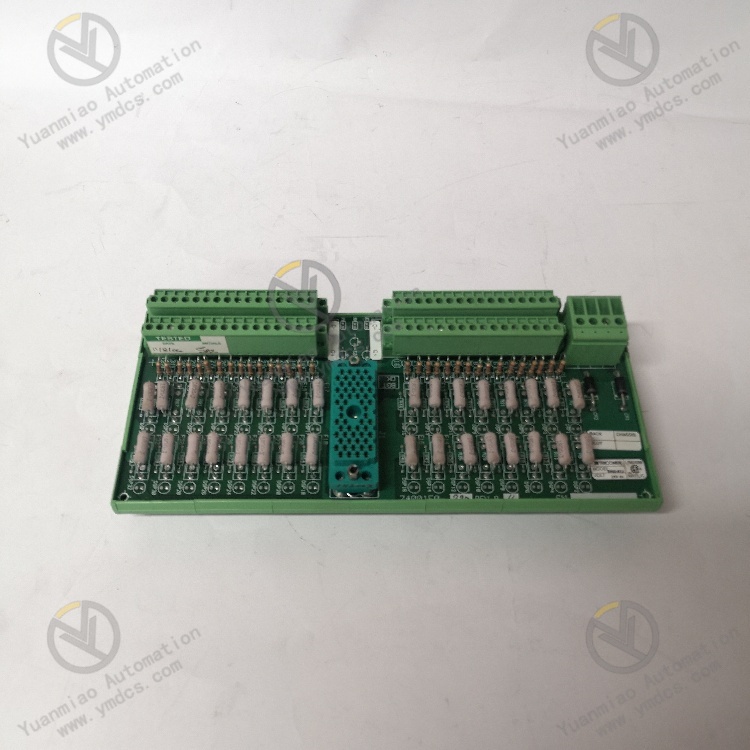

TRICONEX 9566-8XX

I. Overview

TRICONEX 9566-8XX is a module that occupies a core position in the Safety Instrumented System (SIS). This module is designed specifically for high-safety-level industrial process control. With its advanced Triple Modular Redundancy (TMR) architecture, it performs excellently in various complex industrial environments with extremely high reliability requirements. Its core value lies in providing solid and reliable safety guarantees for industrial production, ensuring that industrial processes can still operate safely, stably, and efficiently in the face of various potential faults and complex working conditions.

TRICONEX 9566-8XX is a module that occupies a core position in the Safety Instrumented System (SIS). This module is designed specifically for high-safety-level industrial process control. With its advanced Triple Modular Redundancy (TMR) architecture, it performs excellently in various complex industrial environments with extremely high reliability requirements. Its core value lies in providing solid and reliable safety guarantees for industrial production, ensuring that industrial processes can still operate safely, stably, and efficiently in the face of various potential faults and complex working conditions.

In the petrochemical industry, there are many dangerous links involving flammable, explosive, high-temperature, and high-pressure conditions throughout the entire process from crude oil extraction to refining and processing. The TRICONEX 9566-8XX module conducts real-time and accurate monitoring and control of key parameters such as the temperature and pressure of reaction kettles. Once there are abnormal fluctuations in parameters, it quickly activates emergency shutdown or safety protection measures in accordance with preset safety logic, avoiding serious accidents such as explosions and leaks, and effectively ensuring the safety of production facilities, personnel lives, and the surrounding environment. In the power industry, whether it is the operation of generator sets in power stations or the power transmission in substations, this module closely monitors the operating status of equipment, promptly detects potential equipment faults, maintains the stability and reliability of power supply, and prevents large-scale power outages caused by equipment failures that affect social production and life.

II. Technical Parameters

- Power Parameters: Adopts 24V DC power supply. This common industrial DC voltage is stable and has strong anti-interference ability, providing a solid power support for the stable operation of the module. The input current is 5A, and the output current is 2A, which can meet the power demand of various industrial equipment.

- Operating Temperature Range: Has an extremely wide operating temperature range, from -40°C to 70°C. It can operate stably whether in cold outdoor industrial work scenarios or high-temperature industrial production workshops, showing strong environmental adaptability and greatly expanding its application range.

- Signal Processing Capability: Supports 16 channels of digital input/output, which can quickly and accurately collect and transmit various digital signals to achieve precise control of industrial equipment. At the same time, it is equipped with an analog signal median selection mechanism, which can effectively process analog signals and improve the accuracy and reliability of signal processing.

- Communication Capability: It has a variety of communication protocols, compatible with mainstream industrial communication protocols such as Modbus, OPC UA, and Ethernet. It can realize efficient and stable data interaction with various industrial instruments, controllers, and upper monitoring systems, facilitating the construction of a comprehensive and intelligent industrial automation control system.

- Modular Design: Adopts a modular slot design and supports hot-swap function. This feature allows for convenient installation, replacement, or upgrading of the module during system operation, greatly improving the convenience and work efficiency of system maintenance and reducing production downtime caused by system maintenance.

- Safety Certification: Has passed the SIL 2 safety level certification and strictly complies with international authoritative safety standards such as IEC 61508. This indicates that the module has reached a high level in terms of safety performance and can meet the strict requirements for safety control in high-risk industrial scenarios.

III. Functional Features

- High Reliability: Uses Triple Modular Redundancy (TMR) technology, with three identical and synchronously operating system branches built-in. Each branch independently executes the control program and conducts real-time data comparison with the other two branches. With the help of a hardware voting mechanism, all digital inputs and outputs are evaluated and verified, and analog inputs are processed through median selection. Even if a single branch suddenly fails, the system can still output correct control signals based on the information from the other two normal branches, ensuring the continuous and stable operation of the system, fundamentally eliminating the impact of single-point faults on the system, and significantly improving the reliability and availability of the system.

- Strong Logic Control Capability: Can execute complex safety logic control and monitoring functions, and can quickly and accurately make decisions and output corresponding control commands according to changes in input signals. In the industrial production process, it conducts comprehensive monitoring and intelligent control of the operating status of various equipment to ensure that the production process complies with safety regulations and process requirements.

- Accurate Signal Processing: Shows extremely high precision in the signal processing process, and can accurately capture and transmit the status information of external equipment. Both digital signals and analog signals can be processed efficiently and accurately, providing a reliable data basis for the control system and helping industrial production achieve high-precision control.

- Excellent Anti-Interference Ability: Through technical means such as electrical isolation, it effectively blocks the impact of external electrical interference on the system. It can still operate stably in complex and changeable industrial environments with strong electromagnetic interference, ensuring the accuracy and stability of signal transmission and preventing the system from malfunctioning due to external interference factors.

- Flexible Expansion Configuration: The modular design endows it with strong flexibility. It can flexibly expand the number of input and output channels or add other functional modules according to the needs of actual application scenarios. At the same time, it can be seamlessly integrated with Triconex main chassis and expansion chassis, easily meeting the diverse needs of industrial projects of different scales for the system, and realizing personalized customization and continuous upgrading and optimization of the system.

IV. Application Fields

- Chemical and Energy Industries: In chemical production, it conducts real-time monitoring and control of the operating parameters of key equipment such as reaction kettles and distillation towers. For example, it monitors parameters such as pressure, temperature, and liquid level in the reaction kettle in real-time. When the parameters exceed the safe range, it quickly activates the corresponding safety interlock devices, adjusts the equipment operating status or performs emergency shutdown to prevent accidents such as uncontrolled chemical reactions and material leaks. In the energy field, whether in oil extraction, natural gas transmission, or coal processing, this module plays an important role in ensuring the safe and stable process of energy production and transmission.

- Power Systems: In power stations, it is used to monitor and control the operating status of key equipment such as generator sets and transformers. It collects operating parameters of equipment in real-time, such as temperature, vibration, current, and voltage, and through data analysis, promptly discovers potential fault hidden dangers of equipment, and takes corresponding measures for early warning and handling to ensure the continuity and stability of power production. In substations, it realizes the monitoring and protection of the power transmission process to ensure the safe and reliable operation of the power grid.

- Rail Transit: In rail transit systems, it conducts safety monitoring and control of train operation signal systems, power supply systems, etc. For example, through monitoring the status of equipment such as track circuits and signal machines, it ensures the accurate transmission and display of train operation signals, guaranteeing the safety of train operation. At the same time, it monitors and adjusts parameters such as voltage and current of the power supply system to provide stable power support for train operation.

- Other High-Risk Industries: It is also a core component to ensure safe production in high-risk industries such as metallurgy, pharmaceuticals, and water treatment. In the metallurgical industry, it monitors the operation of equipment such as blast furnaces and converters to ensure the safety of the production process; in the pharmaceutical industry, it monitors the operating status of pharmaceutical production equipment to ensure that the pharmaceutical production process meets strict quality and safety standards; in the water treatment industry, it controls sewage treatment equipment and water supply equipment to ensure that water quality meets standards and water supply is safe.