Description

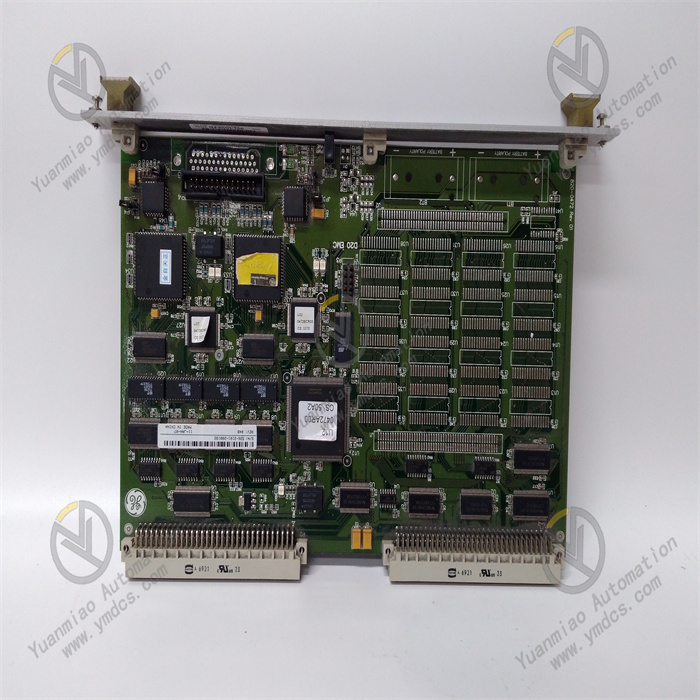

GE WES5120 5120-1506

I. Overview

This product is originally produced in the United States. Its production and manufacturing follow strict quality standards and technological processes to ensure the high quality and reliability of the product. In the context of global trade, it can be transported through major ports such as Shanghai, Yiwu, and Shenzhen, and can be conveniently and quickly delivered to industrial users around the world, meeting the needs of industrial enterprises in different regions for advanced automation control equipment.

II. Technical Parameters

- Interface Type: Equipped with multiple communication interfaces, including the common Ethernet interface, which can realize high-speed and stable data transmission, facilitating connection with other devices that support Ethernet communication, such as servers, upper computers, intelligent sensors, etc., to build an efficient data interaction network. At the same time, it may also be equipped with serial communication interfaces such as RS-485. This type of interface has the characteristics of strong anti-interference ability and long transmission distance, and is suitable for industrial on-site environments where data transmission speed is not high, but communication stability and anti-interference are highly required. It can communicate with various industrial instruments, small controllers and other devices.

- Communication Protocol: Supports a variety of commonly used industrial communication protocols, such as Modbus protocol, which enables it to seamlessly connect with a large number of devices on the market that meet Modbus standards, realizing accurate data exchange and collaborative work between devices. Whether in a newly built automation system or upgrading and transforming an existing system, GE WES5120 5120-1506 can easily integrate into different industrial network architectures relying on its wide protocol compatibility.

Data Processing Performance

- Processor Performance: Built-in high-performance processor with strong data processing capability, which can quickly analyze, calculate and process various collected industrial data. It can process a large number of analog and digital input signals in real time, and generate corresponding control commands according to preset control strategies to ensure precise control of industrial processes. Its data processing speed and calculation accuracy can meet the needs of most industrial automation scenarios, and can ensure the real-time and stability of the system even in complex industrial environments.

- Memory and Storage: Has sufficient memory space for temporarily storing data and programs during operation to ensure the smooth operation of the system. At the same time, it may be equipped with a certain capacity of non-volatile storage devices, such as flash memory, for storing important configuration information, historical data, etc. Even if the device is powered off, these key data will not be lost, facilitating the device to quickly resume normal working status after restarting, and providing data support for subsequent data analysis and fault troubleshooting.

Input and Output Characteristics

- Analog Input and Output: Equipped with multiple analog input channels, which can be connected to various analog sensors, such as temperature sensors, pressure sensors, flow sensors, etc., to accurately collect analog signals on the industrial site and convert them into digital signals for the processor to process. The accuracy of analog input is usually high, which can meet the requirements of high-precision monitoring of industrial parameters. In addition, it also has analog output channels, which can be used to control some actuators that need continuous adjustment, such as control valves, etc., and realize continuous and precise control of industrial processes by outputting accurate analog signals.

- Digital Input and Output: Configured with rich digital input and output interfaces. Digital input can receive various switch signals, such as the start-stop status of equipment, the status of limit switches, etc., for monitoring the operating status of industrial equipment. Digital output can control relays, contactors and other devices to realize logical control of industrial equipment, such as start-stop control of motors, sequence control of equipment, etc. The response speed of digital input and output is fast, which can meet the needs of industrial automation systems for rapid control and logical judgment.

Environmental Adaptability

- Operating Temperature Range: Can work stably in a wide temperature range, generally adaptable to a temperature range from -20°C to 60°C or even wider. This enables it to operate normally in various harsh industrial environments, whether in industrial plants in cold regions or high-temperature production workshops, it can reliably complete its control tasks without being affected by temperature changes.

- Relative Humidity: Can work normally in an environment with a relative humidity of 5%-95% (non-condensing). In humid industrial environments, such as production sites in chemical, food processing and other industries, the internal circuits and components of the equipment will not have problems such as short circuits and corrosion due to moisture, ensuring the long-term stable operation of the equipment. At the same time, in dry environments, it can also effectively avoid damage to the equipment caused by static electricity and other issues.

- Protection Level: May have a high protection level, such as IP54 or higher. The IP54 protection level can effectively prevent dust from entering the equipment, avoid the impact of dust on electronic components, and at the same time can protect against water splashes from all directions, preventing water from damaging the equipment. This protection level enables GE WES5120 5120-1506 to adapt to relatively harsh industrial on-site environments, such as dusty mines, outdoor workplaces that may have water splashes, etc.

III. Functional Characteristics

High-Precision Control: Relying on advanced digital signal processing technology, it can realize high-precision digital signal acquisition and processing. When monitoring and controlling industrial process parameters, it can accurately obtain the signals from sensors and perform rapid and accurate analysis and calculation. For example, in the control process of parameters such as temperature and pressure, the control accuracy can be controlled within a very small range, meeting the strict requirements of industrial production for product quality and process stability, and effectively improving product qualification rate and production efficiency.

Flexible Programming and Configuration: Supports multiple programming methods and configuration methods. Users can program it using common industrial programming languages such as ladder diagrams and function block diagrams according to the needs of actual industrial application scenarios to realize personalized control logic. At the same time, through special configuration software, it is convenient to set and adjust the communication parameters, input and output parameters, control strategies of the equipment, etc. This flexibility enables GE WES5120 5120-1506 to adapt to the diverse control needs of different industries and processes, whether it is simple stand-alone control or complex large-scale automated production line control, it can easily cope with.

Real-Time Monitoring and Alarm Function: Has the function of real-time monitoring of its own operating status and industrial process parameters. It can monitor key components of the equipment in real time, such as processors, memory, communication interfaces, etc. Once abnormal situations are found, such as excessive temperature, low voltage, communication failure, etc., it can send out alarm signals in a timely manner. At the same time, it monitors important parameters in the industrial process in real time. When the parameters exceed the preset normal range, it immediately triggers the alarm mechanism, and informs the operators in a timely manner through sound and light alarms, SMS notifications, email reminders, etc., so that corresponding measures can be taken to deal with it, avoiding the further expansion of faults, and ensuring the safety and stability of industrial production.