Description

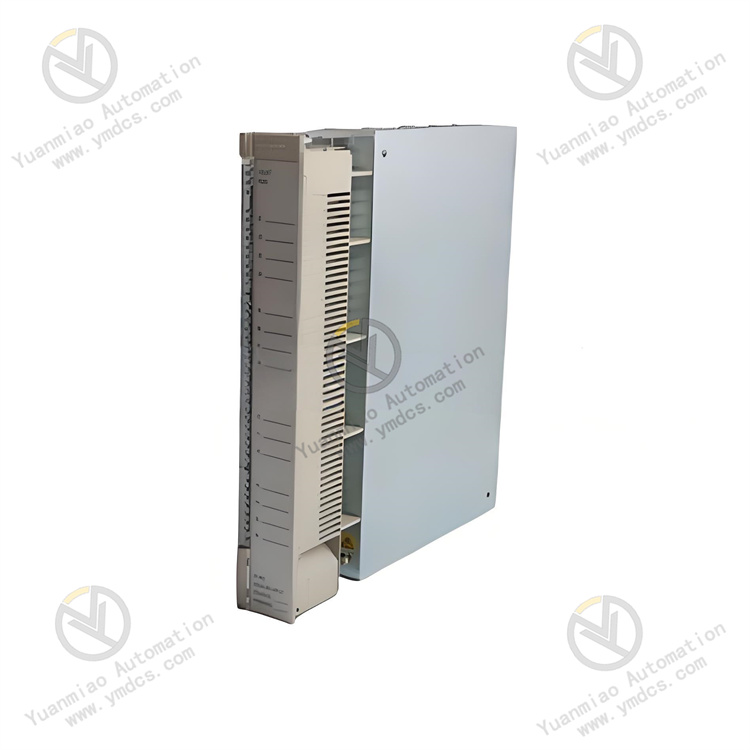

GE UR6AH

I. Product Overview

This module is mainly used in industrial automation and control systems, playing a key role in providing digital input and output functions for the system, and serving as an important bridge connecting various external devices and control systems. It can accurately transmit digital signals from external devices to the control system, and at the same time convert instructions from the control system into signals that drive external devices, playing a connecting role in the entire industrial electrical system to ensure the stable operation and efficient control of the system.

II. Functional Features

GE UR6AH is equipped with abundant digital input and output channels, providing the system with strong signal processing capabilities. It is usually equipped with multiple digital input and output channels. For example, a common configuration includes 8 digital inputs, 2 Form-A outputs and 2 Form-C outputs. These channels can quickly and accurately receive digital signals from external devices such as buttons and sensors, and stably output instruction signals from the control system to executive components such as indicator lights and relays. Taking the start-stop control of equipment on the production line as an example, after the operator presses the start button, the digital signal generated can be quickly captured by the input channel of UR6AH. After internal processing, the output channel controls the start relay of the corresponding equipment, realizing rapid response and precise control of the equipment.

(2) Reliable Signal Isolation

This module has a reliable signal isolation function and performs excellently in electrical isolation. Through a special design, it can effectively achieve electrical isolation between the relay system and external circuits. This not only greatly improves the safety of the system, but also significantly reduces electrical noise interference, ensuring the stability and accuracy of signal transmission. In complex industrial electromagnetic environments, electrical noise is likely to interfere with signal transmission, leading to system misoperation, while the signal isolation function of UR6AH can effectively avoid such problems. For example, in large factory workshops, many motors, frequency converters and other equipment generate strong electromagnetic interference, and UR6AH can ensure that input and output signals are not affected, maintaining stable operation of the system.

This module has a reliable signal isolation function and performs excellently in electrical isolation. Through a special design, it can effectively achieve electrical isolation between the relay system and external circuits. This not only greatly improves the safety of the system, but also significantly reduces electrical noise interference, ensuring the stability and accuracy of signal transmission. In complex industrial electromagnetic environments, electrical noise is likely to interfere with signal transmission, leading to system misoperation, while the signal isolation function of UR6AH can effectively avoid such problems. For example, in large factory workshops, many motors, frequency converters and other equipment generate strong electromagnetic interference, and UR6AH can ensure that input and output signals are not affected, maintaining stable operation of the system.

(3) Flexible Support for Communication Protocols

GE UR6AH supports a variety of mainstream communication protocols such as Modbus, PROFIBUS, PROFIBUS, etc., enabling it to seamlessly integrate with various types of control systems and equipment. Whether it is a traditional industrial automation system or an emerging smart factory control system, UR6AH can easily integrate into them by virtue of its flexible adaptability to communication protocols, realizing efficient data exchange and collaborative control. In an automated production line containing multi-brand equipment, UR6AH can conduct data interaction with the host computer through the Modbus protocol, and communicate with other field devices using the PROFIBUS protocol at the same time, ensuring the smooth flow of information in the entire production line and improving production efficiency.

GE UR6AH supports a variety of mainstream communication protocols such as Modbus, PROFIBUS, PROFIBUS, etc., enabling it to seamlessly integrate with various types of control systems and equipment. Whether it is a traditional industrial automation system or an emerging smart factory control system, UR6AH can easily integrate into them by virtue of its flexible adaptability to communication protocols, realizing efficient data exchange and collaborative control. In an automated production line containing multi-brand equipment, UR6AH can conduct data interaction with the host computer through the Modbus protocol, and communicate with other field devices using the PROFIBUS protocol at the same time, ensuring the smooth flow of information in the entire production line and improving production efficiency.

III. Technical Parameters

Power input: It supports a wide range of power inputs. The common AC input voltage range is 100 - 240V AC, which can adapt to the power environment of different industrial sites and reduce adaptation problems caused by power differences; the DC input is usually 24V DC, meeting the DC power supply needs of most industrial equipment. Moreover, the power module has good anti-interference ability, which can ensure the stable operation of the module even when the power supply voltage fluctuates or there is harmonic interference.

Input and output parameters: In terms of digital input, taking 24V DC logic level as an example, the input impedance is usually about 470kΩ, which can effectively match the output characteristics of common sensors and switchgear to ensure accurate acquisition of input signals; the digital output adopts the form of relay output with strong contact capacity, such as up to 250V AC/DC, 10A (different models may vary slightly). It can reliably drive various loads, including indicator lights, small relays, solenoid valves and other equipment. The output delay is extremely short, generally less than 2ms, meeting application scenarios with high requirements for response speed.

(2) Physical Parameters

Dimensions: The module is compact in design, with general dimensions of (length) 133mm x (width) 75mm x (height) 25mm (there may be slight differences in different versions). This compact design allows it to be easily installed in electrical control cabinets with limited space, saving valuable installation space and facilitating system integration and wiring.

Weight: It is relatively light, usually around 0.2kg, which is convenient for handling and installation operations. At the same time, it reduces the load requirements on structures such as mounting brackets, improving the overall stability of the system.

Protection level: The protection level of the module itself reaches IP20, which can effectively prevent dust. It is suitable for installation in environments with relatively good protection such as control cabinets. If equipped with an additional protective shell, the protection level can be further improved to adapt to harsher industrial environments.

Dimensions: The module is compact in design, with general dimensions of (length) 133mm x (width) 75mm x (height) 25mm (there may be slight differences in different versions). This compact design allows it to be easily installed in electrical control cabinets with limited space, saving valuable installation space and facilitating system integration and wiring.

Weight: It is relatively light, usually around 0.2kg, which is convenient for handling and installation operations. At the same time, it reduces the load requirements on structures such as mounting brackets, improving the overall stability of the system.

Protection level: The protection level of the module itself reaches IP20, which can effectively prevent dust. It is suitable for installation in environments with relatively good protection such as control cabinets. If equipped with an additional protective shell, the protection level can be further improved to adapt to harsher industrial environments.

(3) Environmental Parameters

Operating temperature: The operating temperature range is -20℃ to +70℃, which can adapt to cold storage environments in cold regions and industrial production workshops in high-temperature environments. Whether in severe cold winters or hot summers, it can ensure the normal and stable operation of the module, ensuring that the industrial automation system is not affected by ambient temperature.

Humidity adaptation: It can work normally in an environment with a relative humidity of 5% to 95% (non-condensing). It has an excellent moisture-proof design and can cope with humid environments such as factory workshops in rainy areas in the south and underground distribution rooms, avoiding electrical short circuits, corrosion and other faults caused by humidity problems, and prolonging the service life of the module.

Operating temperature: The operating temperature range is -20℃ to +70℃, which can adapt to cold storage environments in cold regions and industrial production workshops in high-temperature environments. Whether in severe cold winters or hot summers, it can ensure the normal and stable operation of the module, ensuring that the industrial automation system is not affected by ambient temperature.

Humidity adaptation: It can work normally in an environment with a relative humidity of 5% to 95% (non-condensing). It has an excellent moisture-proof design and can cope with humid environments such as factory workshops in rainy areas in the south and underground distribution rooms, avoiding electrical short circuits, corrosion and other faults caused by humidity problems, and prolonging the service life of the module.

IV. Application Scenarios

In manufacturing automation production lines, GE UR6AH plays a core role. For example, in automobile manufacturing workshops, it is used to control the start and stop of various equipment on the production line, the movement of material handling robots, and the operation of automated assembly equipment. Through its precise digital input and output functions, it realizes the automated operation of the production line, improving production efficiency and product quality. After detecting the signal that a certain process is completed, UR6AH can quickly control the handling robot to transfer the workpiece to the next process, ensuring the efficient connection of the production line.

(2) Process Control Systems

In process control industries such as chemical industry and electric power, UR6AH is used to monitor and control various parameters in the production process. For example, in chemical production, sensor signals such as temperature, pressure and liquid level of the reaction kettle are monitored and enter the control system through the input channel of UR6AH. When the parameters exceed the preset range, the control system controls the actions of corresponding valves, pumps and other equipment through the output channel of UR6AH to adjust the production process and ensure production safety and stability. In power systems, it can be used for status monitoring and control of substation equipment, uploading equipment operating status signals to the monitoring system, and receiving control instructions to realize remote operation of switches, knife switches and other equipment.

In process control industries such as chemical industry and electric power, UR6AH is used to monitor and control various parameters in the production process. For example, in chemical production, sensor signals such as temperature, pressure and liquid level of the reaction kettle are monitored and enter the control system through the input channel of UR6AH. When the parameters exceed the preset range, the control system controls the actions of corresponding valves, pumps and other equipment through the output channel of UR6AH to adjust the production process and ensure production safety and stability. In power systems, it can be used for status monitoring and control of substation equipment, uploading equipment operating status signals to the monitoring system, and receiving control instructions to realize remote operation of switches, knife switches and other equipment.

(3) Robot Control

In the field of robot control, UR6AH serves as a key interface for the interaction between the robot control system and the external environment. It receives signals from external sensors (such as visual sensors, force sensors, etc.) to provide environmental information for the robot, and at the same time outputs the action instructions of the robot control system to motor drivers, actuators, etc., realizing precise motion control of the robot. In the automatic sorting robot system in the logistics and warehousing industry, UR6AH can control the robot arm to accurately grab and place goods according to the cargo information identified by the visual sensor, improving the efficiency of logistics sorting.

In the field of robot control, UR6AH serves as a key interface for the interaction between the robot control system and the external environment. It receives signals from external sensors (such as visual sensors, force sensors, etc.) to provide environmental information for the robot, and at the same time outputs the action instructions of the robot control system to motor drivers, actuators, etc., realizing precise motion control of the robot. In the automatic sorting robot system in the logistics and warehousing industry, UR6AH can control the robot arm to accurately grab and place goods according to the cargo information identified by the visual sensor, improving the efficiency of logistics sorting.