Description

GE WESDAC D20ME 18-MAR-13

I. Product Overview

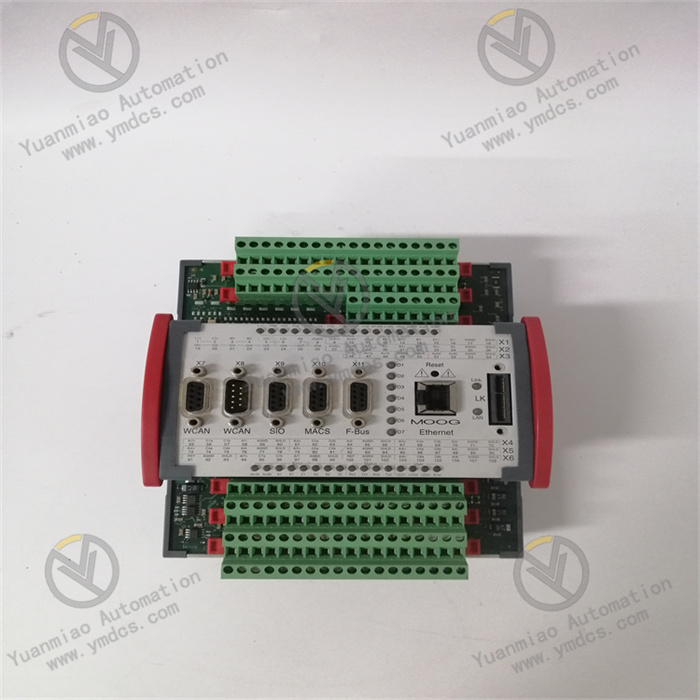

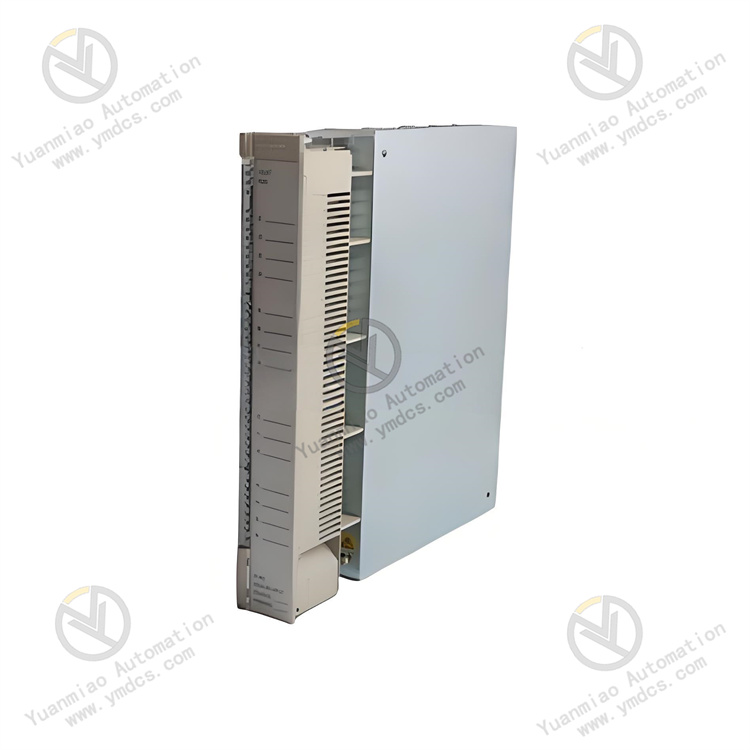

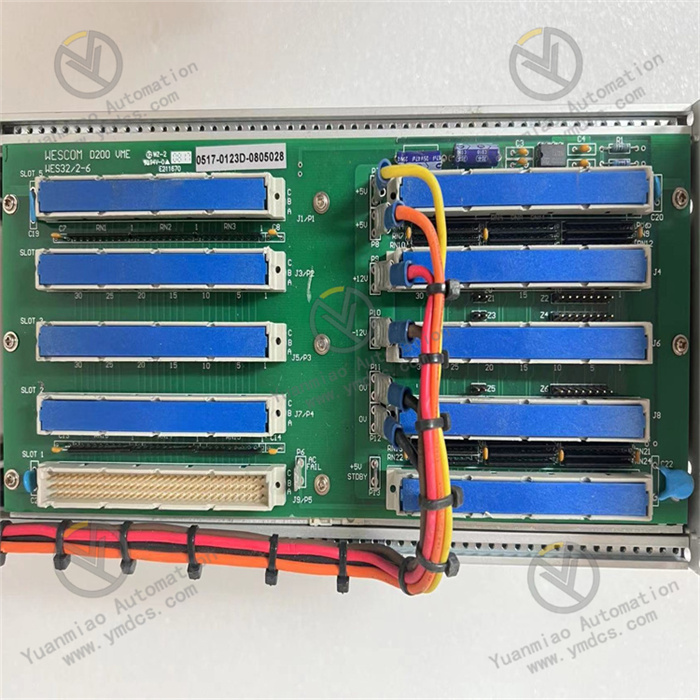

From the perspective of hardware architecture, the module adopts a compact layout after in-depth optimization. This exquisite design enables it to cleverly adapt to the actual situation of limited space inside various control cabinets, creating extremely favorable conditions for convenient and efficient combined installation with other equipment. Its shell is carefully made of high-strength industrial-grade materials, which not only has excellent anti-vibration and anti-impact performance, but also has good dust-proof characteristics. With these characteristics, the module can operate stably for a long time in complex and harsh industrial environments such as dusty and frequently vibrating ones, effectively protecting the internal precision circuit components, thus greatly extending its service life and ensuring that the operation reliability is always at a high level.

GE WESDAC D20ME 18 - MAR - 13 module focuses on the accurate processing of complex signals and the efficient output of control commands to various equipment. It can accurately receive signals from various sensors such as temperature sensors, pressure sensors and flow sensors, convert physical quantities into electrical signals, and then carry out subsequent processing and analysis. At the same time, according to the preset complex control logic, it quickly and accurately sends control commands to the actuator to realize the refined and precise regulation of industrial equipment. In the entire industrial automation system, it is like a bridge, closely connecting the on-site perception layer and the control layer to ensure the smooth operation of the system.

II. Performance Parameters

Operating Voltage: The module is compatible with a wide range of voltage inputs, supporting both 20 - 60V DC, 100 - 300V DC and 85 - 264V AC. This wide range of voltage adaptation capability enables it to match various power supply systems in industrial sites well, greatly improving the convenience of system integration. Stable voltage input lays a solid foundation for the normal and efficient operation of various functions of the module.

Input and Output Characteristics: Its input and output channels have excellent performance and high flexibility. The input channel shows strong compatibility and can easily accept various types of signals such as 4 - 20mA current signals and 0 - 10V voltage signals, fully meeting the diverse signal access needs of different sensors. The output channel has a certain driving capacity and can directly drive small relays, solenoid valves and other actuators. Although the specific number of input and output channels needs to refer to the detailed product manual, generally speaking, its configuration can meet the basic needs of most industrial automation projects, and can be flexibly expanded through expansion modules when necessary. The output current is usually in the range of 1A - 5A, but the specific value will vary according to different application scenarios and configurations.

(2) Environmental Adaptability

Operating Temperature: It has a wide operating temperature range and can run stably in the temperature range of - 40℃ to + 70℃. This feature enables it to perfectly adapt to the common large temperature changes in industrial production workshops. Whether in cold winter or hot summer, it can always maintain stable performance, ensuring that the control process is not affected by temperature fluctuations at all. GE WESDAC D20ME 18 - MAR - 13 can perform reliably in both cold heavy industry plants in the north and hot and humid electronic manufacturing workshops in the south.

Operating Temperature: It has a wide operating temperature range and can run stably in the temperature range of - 40℃ to + 70℃. This feature enables it to perfectly adapt to the common large temperature changes in industrial production workshops. Whether in cold winter or hot summer, it can always maintain stable performance, ensuring that the control process is not affected by temperature fluctuations at all. GE WESDAC D20ME 18 - MAR - 13 can perform reliably in both cold heavy industry plants in the north and hot and humid electronic manufacturing workshops in the south.

Relative Humidity: The module can still work normally in an environment with a relative humidity of 5% - 95% (non-condensing). This makes it particularly suitable for humid industrial places such as food processing workshops and water treatment plants, effectively avoiding circuit short circuits, component corrosion and other faults caused by humidity problems, and strongly ensuring the long-term reliable operation of the module. Even in a humid environment, the precision circuits inside the module can be properly protected and work continuously and stably.

Anti-electromagnetic Interference: It strictly complies with industrial-grade electromagnetic compatibility standards and has strong anti-electromagnetic interference ability. In industrial sites, motors, frequency converters, high-voltage equipment, etc. will generate strong electromagnetic interference, and this module can effectively resist these interferences, ensure the accuracy of signal transmission and the reliable execution of control commands, avoid misoperations caused by interference, and maintain the stable operation of the system. Whether in large factories with complex electromagnetic environments or around substations with dense power facilities, GE WESDAC D20ME 18 - MAR - 13 can work stably to ensure the accurate transmission of signals and the accurate execution of control commands.

(3) Response Speed

The signal processing and response speed of the module are excellent, and the response time of input signals is usually at the millisecond level. For specific values, please refer to the product manual. Such a fast response speed enables it to quickly capture the subtle changes of on-site signals and output corresponding precise control commands in a timely manner, which fully meets the strict real-time requirements of industrial automation systems and ensures timely and accurate regulation of equipment. In some industrial scenarios with high requirements for response speed, such as high-speed automated production lines and real-time monitored chemical reaction processes, the module can respond quickly, providing strong support for the efficient and stable operation of the system.

The signal processing and response speed of the module are excellent, and the response time of input signals is usually at the millisecond level. For specific values, please refer to the product manual. Such a fast response speed enables it to quickly capture the subtle changes of on-site signals and output corresponding precise control commands in a timely manner, which fully meets the strict real-time requirements of industrial automation systems and ensures timely and accurate regulation of equipment. In some industrial scenarios with high requirements for response speed, such as high-speed automated production lines and real-time monitored chemical reaction processes, the module can respond quickly, providing strong support for the efficient and stable operation of the system.

III. Functional Characteristics

Precise Filtering and Amplification: It has extremely accurate signal processing capability, and can carry out a series of complex processing operations such as filtering, amplification and conversion for input analog or digital signals. Through efficient filtering algorithms, it can effectively remove noise interference in the signal, greatly improve the accuracy and stability of the signal, and provide real and reliable original data for the subsequent control system. For example, when collecting signals from pressure sensors, it can accurately filter out interference signals caused by pipeline vibration, ensuring that the pressure data truly reflects the actual working conditions. In industrial production, signals are often subject to various interferences, and the module's strong signal processing capability can ensure the accuracy of data and provide a reliable basis for subsequent decision-making and control.

Range Calibration and Linearization: It supports detailed range calibration and linearization processing of input signals. Users can set targeted parameters for the module according to the unique characteristics of the actual sensor, so as to establish an accurate corresponding relationship between the collected signal and the actual physical quantity. This function significantly improves the measurement accuracy and can fully meet the strict requirements of high-precision control scenarios. For some industries with high requirements for measurement accuracy, such as precision instrument manufacturing and high-end electronic production, this function can ensure the accuracy of measurement data, improve product quality and production efficiency.

(2) Control Logic Execution

Programmable Control: With built-in programmable control logic, users can flexibly write programs and configure parameters for the module with the help of special programming software, so as to realize personalized and customized control strategies. For example, according to the deviation between the input temperature signal and the preset set value, the output control quantity can be automatically and intelligently adjusted to realize efficient closed-loop control of heating equipment, keeping the temperature within the set range. In industrial automation production, different production processes and processes require different control strategies. The programmable feature of the module can meet the diverse needs of users and realize efficient automatic control.

Programmable Control: With built-in programmable control logic, users can flexibly write programs and configure parameters for the module with the help of special programming software, so as to realize personalized and customized control strategies. For example, according to the deviation between the input temperature signal and the preset set value, the output control quantity can be automatically and intelligently adjusted to realize efficient closed-loop control of heating equipment, keeping the temperature within the set range. In industrial automation production, different production processes and processes require different control strategies. The programmable feature of the module can meet the diverse needs of users and realize efficient automatic control.

Linkage Control: It supports collaborative linkage control with various other control devices. Through the communication interface, the module can receive instructions from the superior control system in real time and strictly execute corresponding operations in accordance with the instructions. At the same time, it will also feed back its own operating status and collected data to the superior system in a timely manner, realizing the collaborative work of all links in the entire industrial automation system and improving the overall operating efficiency. In large-scale industrial automation projects, which often involve the collaborative work of multiple equipment and systems, the linkage control function of the module can ensure that all links work closely together, improving production efficiency and the overall performance of the system.

(3) Status Monitoring and Diagnosis

Real-time Status Monitoring: It has a complete status monitoring function, which can monitor the operating status of the module itself in real time and dynamically, covering key information such as power supply voltage and communication status. And through intuitive indicator lights or convenient communication methods, it clearly indicates the status, making it convenient for operators to intuitively understand the working condition of the module at any time. Operators can quickly judge whether the module is running normally by observing the status of the indicator lights, or obtain detailed operating data through the communication interface to find potential problems in time.

Real-time Status Monitoring: It has a complete status monitoring function, which can monitor the operating status of the module itself in real time and dynamically, covering key information such as power supply voltage and communication status. And through intuitive indicator lights or convenient communication methods, it clearly indicates the status, making it convenient for operators to intuitively understand the working condition of the module at any time. Operators can quickly judge whether the module is running normally by observing the status of the indicator lights, or obtain detailed operating data through the communication interface to find potential problems in time.

Self-diagnosis and Alarm: It has a certain degree of self-diagnosis ability. When the module encounters faults or abnormal conditions, such as input signal overrun, communication interruption, etc., it can quickly and timely send out alarm signals and record fault information in detail. This function greatly facilitates maintenance personnel to quickly locate and repair faults, effectively shortening system downtime and reducing production losses. Once a fault occurs, maintenance personnel can quickly determine the cause of the fault according to the alarm information and fault records, and take corresponding repair measures to reduce the impact of equipment downtime on production.