Description

I. Model Decomposition and Meaning

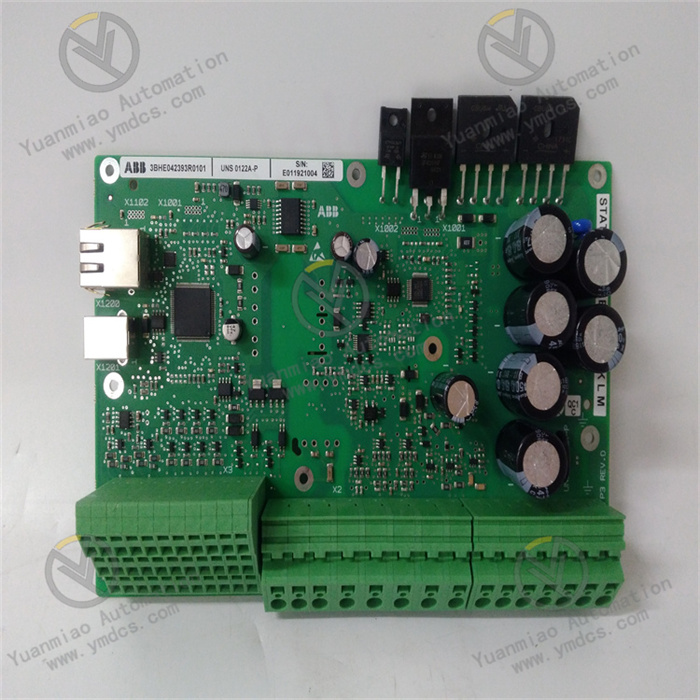

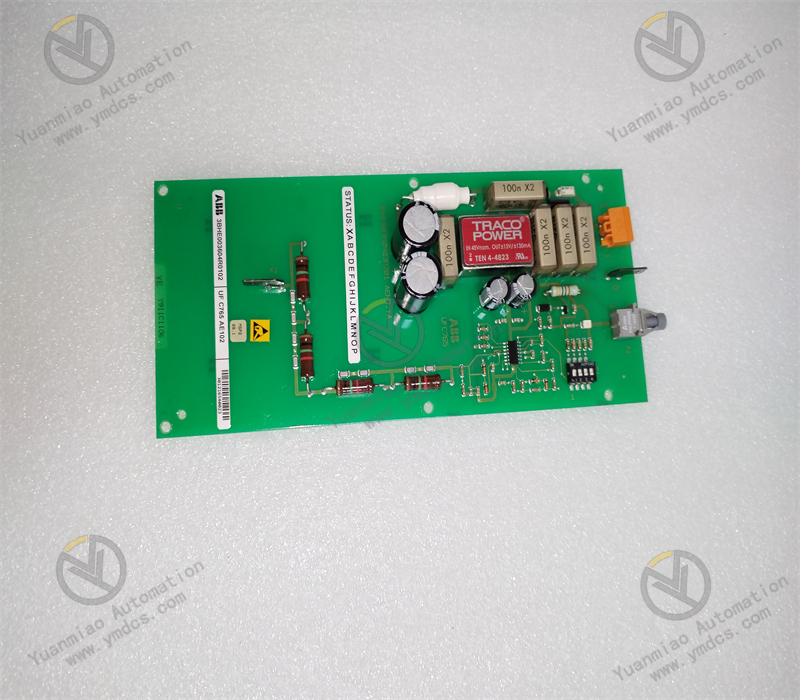

UFC765AE102

- UFC:

Typically represents the control module/unit of ABB frequency converters or control systems (such as the control board of the ACS800 series frequency converters), responsible for signal processing, parameter adjustment, and communication functions. - 765:

Likely indicates the product version or specification. Compared with previous models (e.g., UFC762), it may feature upgraded performance, interfaces, or application scenarios (e.g., higher power, more input/output channels). - AE102:

Probably a configuration code used to distinguish functional differences. For example: - A: Signal type or input/output configuration (e.g., primarily analog signals).

- E: Support for communication protocols (e.g., integrated Ethernet or specific fieldbus).

- 102: Version iteration or functional parameter sequence number.

3BHE003604R0102

- 3BHE:

A standard product prefix of ABB, used to identify low-voltage automation components (such as PLC modules, drive modules, control boards, etc.). - 003604:

A unique part number used to distinguish specific hardware models and configurations. - R0102:

Version number, where: - R: Revision (revised version).

- 0102: Specific version iteration, possibly indicating hardware design optimization or software function upgrades (e.g., compatibility with new protocols, improved stability).

II. Technical Parameters

| Category | Parameter Description |

|---|---|

| Input Signals | - Analog: 0-10V, 4-20mA (high-impedance input, anti-interference design) - Digital: DI channels (support dry contacts/level signals) |

| Output Signals | - Analog: 0-10V, 4-20mA (load capacity ≥500Ω) - Digital: DO channels (relay/transistor output, 24VDC/2A) |

| Communication Interfaces | - RS485/RS232 (Modbus RTU) - Ethernet (e.g., Profinet, EtherNet/IP; if the model contains "E", network functions may be enhanced) |

| Control Functions | - Supports PID control, adaptive regulation, logical operations - Built-in algorithm libraries (e.g., motor control, process control) |

| Accuracy and Speed | - Analog accuracy: ±0.1% FS - Control cycle: ≤10ms (high-speed response) |

| Power Supply | - 24VDC (±10%) or 100-240VAC (wide voltage input, suitable for industrial environments) |

| Operating Environment | - Temperature: -10°C~+55°C - Humidity: ≤90% RH (non-condensing) - Anti-vibration/impact (compliant with industrial standards) |

| Installation Method | - DIN rail mounting or board mounting (compact design, space-saving in control cabinets) |

III. Functional Features

High-Performance Control Core

- Integrated microprocessor supports complex algorithms (e.g., PID auto-tuning, multi-loop control), suitable for scenarios such as motor speed regulation and temperature/pressure control.

- Strong real-time data processing capability enables quick response to on-site signal changes.

Rich Interfaces and Expandability

- Multi-channel analog/digital IO supports custom signal types (e.g., thermocouple, RTD inputs).

- Optional communication modules (e.g., Profibus DP, CANopen) are compatible with ABB and third-party systems (e.g., PLC, SCADA).

High Reliability and Anti-Interference

- Uses industrial-grade components and undergoes rigorous EMC testing, suitable for strong interference environments (e.g., near frequency converters, factory workshops).

- Built-in self-diagnosis function supports fault alarms and status monitoring (e.g., power anomalies, communication interruptions).

Flexible Programming and Debugging

- Supports ABB official software (e.g., DriveWindow, Control Builder) for parameter configuration and program development.

- Visual interface displays real-time waveforms and trend charts, facilitating on-site debugging and control strategy optimization.

Modular Design

- Can be combined with other ABB modules (e.g., UFC760 series, IO modules) to build distributed control systems.

- Supports firmware upgrades to expand functions via software updates (e.g., new communication protocols, optimized control algorithms).

IV. Application Scenarios

Industrial Automation

- Frequency Converter Control: As a control board for ACS800 series frequency converters, it realizes closed-loop control of motor speed and torque.

- Process Control: Adjusts process parameters such as temperature, flow rate, and liquid level in chemical, pharmaceutical, and food industries.

Machinery and Equipment

- Motion control for packaging machinery and printing machinery (combined with servo systems).

- Energy-saving systems for fans and pumps (achieves constant pressure/current control via PID regulation).

Power and Energy

- Logical control and data acquisition for photovoltaic inverters and energy storage systems.

- Monitoring of substation auxiliary equipment (e.g., ventilation and lighting system automation).

V. Operation and Maintenance Recommendations

Installation and Wiring

- Ensure correct power polarity to avoid module damage from reverse connection.

- Use shielded cables for analog signals and keep them away from power lines to reduce interference.

- Wire communication cables according to protocol standards (e.g., RS485 differential signals for Modbus RTU).

Parameter Configuration

- Initialize the module via ABB software to set basic parameters such as input/output types, communication addresses, and control modes.

- When debugging PID parameters, it is recommended to use the auto-tuning function first, then fine-tune based on on-site conditions (e.g., proportional gain, integral time).

Fault Troubleshooting

- Common faults: Communication interruptions (check cables and baud rate matching), abnormal outputs (verify load overload).

- Use the module's LED indicators to judge status (e.g., power light, communication light, fault light).

Maintenance Cycles

- Regularly clean dust from the module surface and check for loose terminal connections.

- It is recommended to perform functional tests every 1-2 years to ensure parameter accuracy and response speed meet requirements.