Description

Technical Parameters

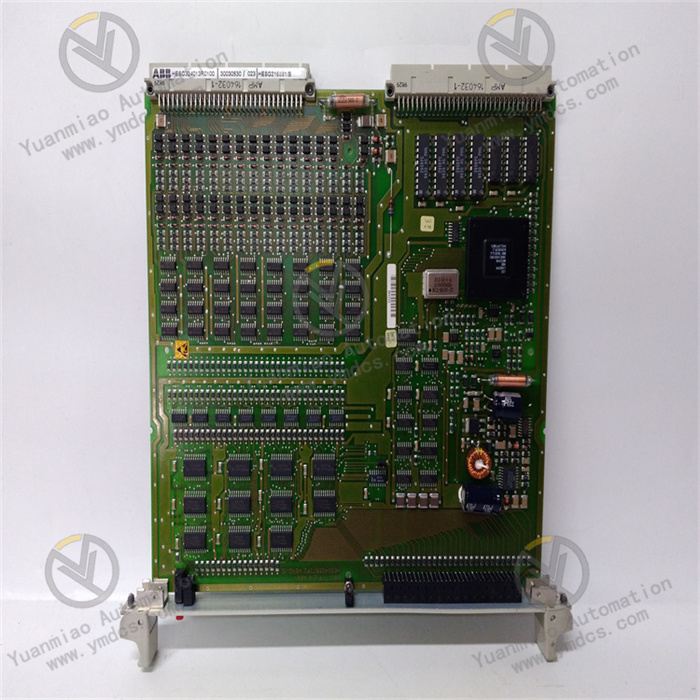

- Processor: It adopts a 32 - bit RISC CPU, which has strong data - processing and logical operation capabilities. It can quickly execute the control programs written by users to achieve various complex control functions.

- Memory: It is usually equipped with 4MB of RAM and 8MB of Flash memory. The RAM is used for temporarily storing running programs and data, supporting fast data reading and writing to ensure the real - time response performance of the controller. The Flash memory is used for storing user - written programs, configuration information, etc. The data will not be lost even in case of a power outage.

- Communication Ports: It is equipped with Ethernet, serial, and USB communication ports. The Ethernet port can be used for high - speed data exchange with other devices or systems to achieve functions such as remote monitoring and data acquisition. The serial port can be connected to devices with serial communication interfaces, such as sensors and actuators. The USB port is convenient for program downloading, uploading, and data transmission with external devices.

- Power Supply: It supports a 24V DC power input. It has good power adaptability and stability, can work normally within a certain voltage fluctuation range, and provides stable power supply for the controller and its connected devices.

- I/O Points: Although it was mentioned earlier that the maximum number of I/O bits for each sub - station is 512 and that for each system is 16384, for the PC - E984 - 685 itself, the configuration may be relatively flexible. Different numbers of input and output modules can be expanded according to actual application requirements to meet the control needs of different numbers of devices such as sensors and actuators.

- Dimensions and Weight: The dimensions are approximately 10.2cm×27.9cm×22.9cm, and the weight is 2.1 kilograms. The overall structure is relatively compact, which is convenient for installation in control cabinets or other places with limited space.

Product Features

- High Reliability: It uses industrial - grade design and manufacturing processes, can operate stably in harsh industrial environments, has strong anti - interference ability, and can adapt to environmental conditions such as high temperature, humidity, and dust.

- Flexibility and Scalability: It supports multiple programming languages and development environments. Users can choose appropriate programming methods to implement control logic according to their own needs. At the same time, the number of I/O points, communication interfaces, etc. can be easily increased through expansion modules to meet the application requirements of different scales and complexities.

- Powerful Communication Ability: It is equipped with multiple communication ports and supports multiple communication protocols, such as Modbus and Profibus. It can be easily integrated with other devices and systems to achieve information interaction and sharing, facilitating the construction of complex industrial automation control systems.

Application Cases

- Industrial Automation Production Lines: In industrial automation production lines such as automobile manufacturing and electronic device production, it is used to control various devices on the production line, such as robots, conveyors, and assembly machines. Through programming, precise control of the production process is achieved, including material handling, part assembly, quality inspection, etc., improving production efficiency and the consistency of product quality.

- Process Control Systems: In the process control of industries such as chemical, pharmaceutical, food and beverage, it can monitor and control process parameters such as temperature, pressure, flow, and liquid level in real - time. By collecting data from sensors, performing logical operations and processing, and sending control signals to actuators, precise adjustment of the production process is achieved to ensure the stability and safety of the production process.

- Machine Control: It is used for the control of various industrial machines, such as injection molding machines, CNC machine tools, and printing machines. It realizes the motion control, action logic control of machines, and collaborative work with other devices, improving the automation level and operating efficiency of machines and reducing the workload and errors of manual operation.

- Energy Management Systems: In fields such as intelligent buildings and factory energy management, it can be used to monitor and control the consumption of energy such as electricity, water, and gas. By communicating with energy metering devices and smart meters, energy data is collected to achieve real - time monitoring, analysis, and optimized management of energy, helping users reduce energy consumption and improve energy utilization efficiency.

The Schneider PC - E984 - 685 is a model in the Modicon 984 series of programmable controllers. Its input and output modules come in various types. Here are some common types:

- Digital Input Modules: They are used to receive digital signals from field devices, such as the status signals of buttons, switches, and proximity sensors. These modules usually have multiple input channels and can convert external digital signals into logic level signals that the PLC can process. For example, the AS - B984 - 100 module has 16 digital input channels, with an operating voltage of 20 - 28V DC and a maximum input response time of 100 microseconds (without filtering).

- Digital Output Modules: They are used to control external digital devices, such as relays, contactors, and indicator lights. They convert the internal logic signals of the PLC into signals that can drive external devices. The output forms of digital output modules can be relay output, transistor output, or thyristor output. For example, a module with 8 relay outputs can generally output a current of up to 1A per channel.

- Analog Input Modules: They are used to collect analog signals from the field, such as continuously changing physical quantities like temperature, pressure, flow, voltage, and current. Analog input modules convert these analog signals into digital signals for the PLC to process and calculate. For example, the 170Aai03000 module is an analog input module with 8 analog input channels. It supports differential input types, and the input range includes +/-10V, +/-20mA, +/-5V, etc., providing a 16 - bit signed data format.

- Analog Output Modules: They convert the digital signals processed by the PLC into analog signals for controlling devices that require analog input, such as frequency converters and control valves. Analog output modules usually have multiple output channels, and each channel can output different analog signals.