Description

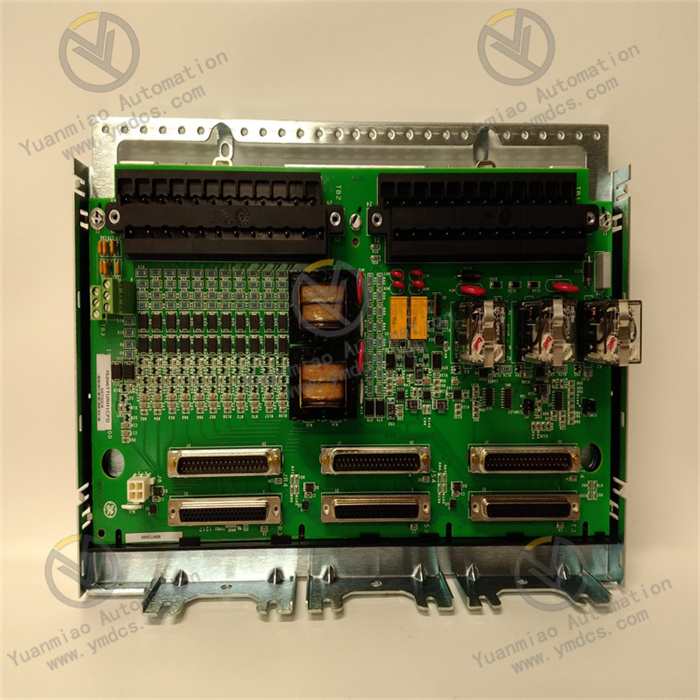

GE IS200TTURH1CFD

The GE IS200TTURH1CFD is a temperature monitoring and control module belonging to the Mark VIe turbine control system. Its core positioning is a "temperature safety monitoring and interlock control unit for critical components of turbine equipment". Its core value lies in integrating GE’s patented algorithms in the turbine control field with high-reliability hardware design, providing an integrated solution of "multi-channel high-precision temperature acquisition + real-time over-temperature early warning + emergency shutdown interlock" for critical parts of gas turbines and steam turbines, such as rotor windings, blades, bearings, and lubricating oil.

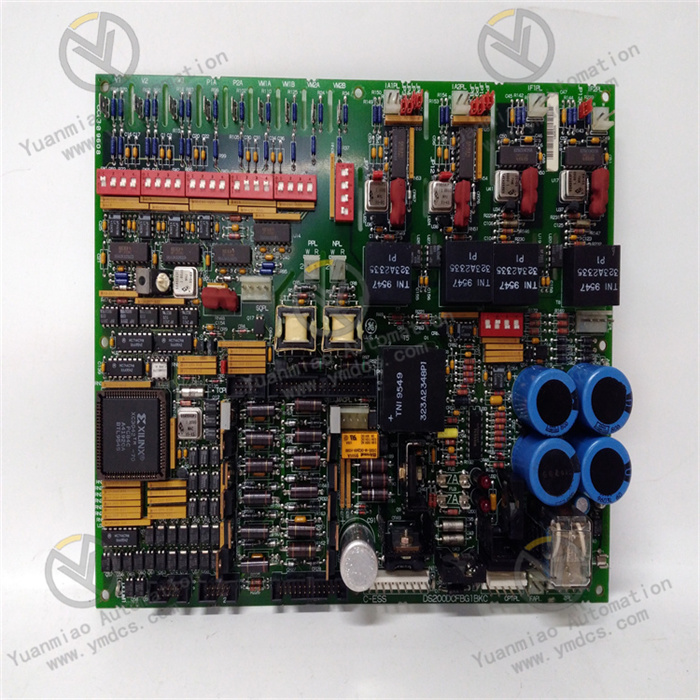

Compared with general-purpose temperature modules, it focuses more on "turbine scenario professionalism" — it supports 32-channel RTD (PT100/PT1000) input, adapting to the temperature monitoring needs of turbines with multiple measurement points and a wide temperature range (-200℃ to 850℃). Meanwhile, it holds SIL 2 safety certification (compliant with IEC 61508) and can operate stably in turbine environments with high vibration (≤5g), high temperature (ambient temperature ≤65℃), and strong electromagnetic interference. When over-temperature is detected in critical components (e.g., bearing temperature >120℃), it can trigger an interlock signal within ≤10ms to cut off fuel supply or initiate emergency shutdown, preventing major faults such as rotor deformation and blade damage caused by overheating of turbine equipment. It is a core component for "safe equipment operation" in industries relying on turbines, such as power generation, petrochemicals, and aerospace.

As a core I/O module of the Mark VIe control system, this module supports seamless integration with GE turbine controllers (e.g., TCIA controller) and HMI (Operator Interface). It is also compatible with general communication protocols such as Modbus TCP and OPC UA, balancing the professionalism of turbine control and the flexibility of system integration. It provides key technical support for "predictive maintenance" and "safety interlock" of turbine equipment.

- 32-Channel High-Density Design: A single module supports 32 RTD input channels, enabling simultaneous temperature monitoring of turbine rotors (8 points), blades (16 points), and bearings (8 points). Compared with general-purpose modules, it reduces installation space by 60%, minimizing the size of turbine control cabinets and wiring complexity.

- 4-Wire PT100 High-Precision Acquisition: Critical channels (e.g., rotor windings) support 4-wire PT100 input, eliminating the impact of wire resistance on measurements (3-wire error ≈±0.5℃, 4-wire error ≤±0.1℃). This ensures accurate rotor temperature measurement at high turbine speeds (e.g., 3000rpm) and prevents false interlocks caused by measurement deviations.

- Wide Temperature Range and High-Speed Sampling: The -200℃ to 850℃ measurement range covers all operating conditions of turbines, from startup (low temperature) to full-load operation (high temperature). The sampling rate of 100 samples/second/channel captures rapid temperature rises of blades during turbine startup (e.g., 10℃/s), providing real-time data support for over-temperature early warning.

- Tiered Thresholds and Flexible Interlock Logic: Each channel is independently configured with two-tier "early warning-interlock" thresholds (e.g., bearing temperature early warning at 110℃, interlock at 120℃). It supports "single-channel interlock" (e.g., over-temperature of a single blade) or "multi-channel AND logic" (e.g., over-temperature of 2+ bearings simultaneously), adapting to the safety requirements of different turbine components (rotor over-temperature requires immediate interlock, while slight blade over-temperature can trigger early warning first).

- SIL 2 Safety Certification and Rapid Response: Certified to IEC 61508 SIL 2, the interlock output response time is ≤10ms, far faster than the safety shutdown requirement for turbines (≤100ms). When rotor winding temperature >150℃ is detected, it can quickly cut off the fuel valve to prevent rotor deformation due to overheating.

- Full-Link Fault Self-Diagnosis: Automatically detects RTD open circuits (displaying "Open Circuit"), short circuits ("Short Circuit"), reverse connections ("Reverse Connection"), as well as module power abnormalities and communication interruptions. Upon fault detection, it immediately triggers audible and visual alarms (red LED flashing on the panel + interlock output maintaining a safe state) and uploads fault information to the HMI, facilitating maintenance personnel to quickly locate issues.

- High Vibration and High-Temperature Resistance: The 5g vibration resistance design adapts to mechanical vibration during turbine operation (e.g., rotor vibration of gas turbines at full load). The 0℃ to 65℃ operating temperature range covers high-temperature environments in turbine rooms (temperature ≤60℃ in summer without air conditioning), ensuring the module operates without crashes or data fluctuations under extreme conditions.

- Strong Electromagnetic Interference Resistance: Turbine generators and frequency converters generate strong electromagnetic radiation. The module uses EMC design (shielding grounding, filter circuits) to ensure temperature acquisition signal fluctuation ≤±0.05℃, avoiding false early warnings or interlocks caused by electromagnetic interference.

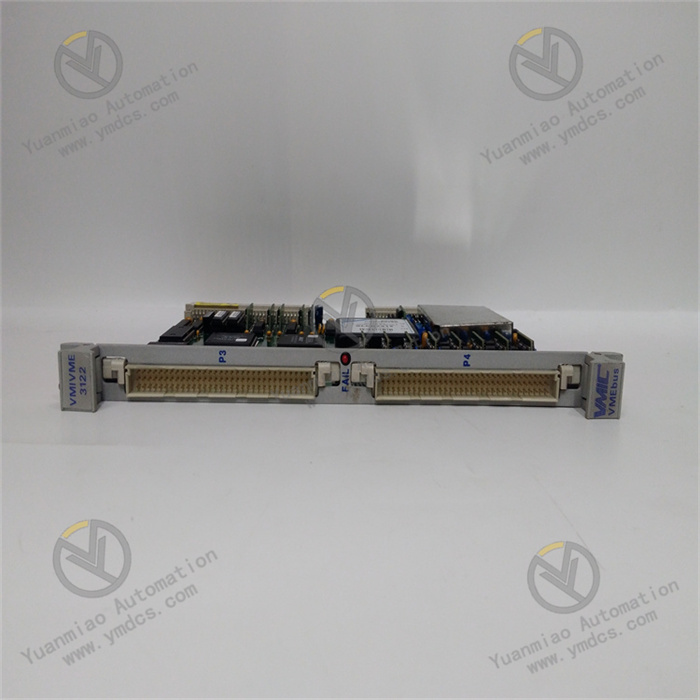

- Dual-Power and Communication Redundancy: Supports 24V DC dual-power redundancy (switching time ≤10ms) and GE high-speed backplane bus redundancy, preventing temperature monitoring interruptions caused by single-point faults and meeting the "no single-point fault" safety design requirement for turbines.

- Seamless Compatibility with Mark VIe System: As a native module of the Mark VIe control system, it can be directly inserted into standard racks and linked with TCIA controllers and turbine HMIs without additional protocol converters. Temperature data and interlock status are displayed in real time on the HMI interface (e.g., rotor temperature trend curve, fault alarm pop-up).

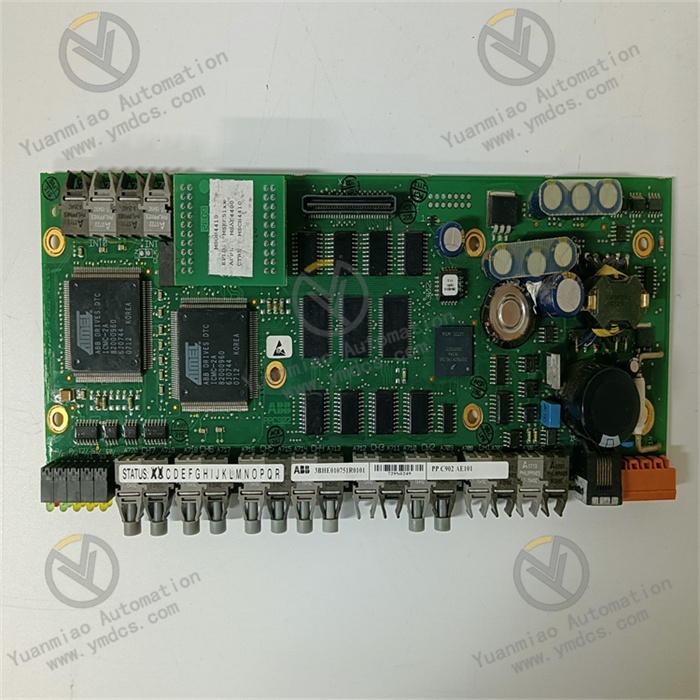

- General Communication and Data Traceability: Optional Modbus TCP and OPC UA protocols enable temperature data upload to plant DCS (e.g., Siemens PCS 7) or cloud platforms (GE Predix) for remote monitoring and predictive maintenance of turbines (e.g., analyzing bearing wear trends via historical temperature curves).

- Visual Configuration and Debugging: Through GE ToolboxST software (a dedicated configuration tool for Mark VIe), temperature thresholds, interlock logic, and sampling rates can be configured graphically. It supports online monitoring of real-time temperature (accuracy 0.1℃) and historical data (storage ≥1 year) for each channel, allowing non-specialized turbine engineers to quickly complete basic configurations.

A 200MW gas turbine generator set requires temperature monitoring of:

- Rotor windings (8 points, PT100 4-wire, normal ≤120℃, interlock ≤150℃);

- Bearings (4 points, PT100 3-wire, normal ≤90℃, early warning ≤110℃, interlock ≤120℃);

- Lubricating oil (2 points, PT100 3-wire, normal ≤50℃, interlock ≤65℃).

The module is required to operate stably in a gas turbine environment with high vibration (≤3g) and turbine room temperature of 30℃-60℃, and support linkage with the Mark VIe controller for emergency shutdown.

- Multi-Channel Temperature Acquisition: Among the 32 channels, 8 are configured as PT100 4-wire (rotor windings), 6 as PT100 3-wire (bearings + lubricating oil), and the remaining channels are for backup. The sampling rate is set to 100 samples/second to capture real-time temperature changes during rotor startup.

- Tiered Interlock Control: When rotor winding temperature >150℃, it triggers "emergency shutdown" interlock (cutting off fuel valve + generator tripping); when bearing temperature >110℃, the HMI pops up an early warning ("Bearing temperature is high"); when bearing temperature >120℃, it triggers "load reduction" interlock (reducing load from 200MW to 150MW); when lubricating oil temperature >65℃, it triggers "lubricating oil pump start/stop" interlock (starting the backup oil pump).

- Redundancy and Monitoring: Dual-power redundancy prevents power outage risks; GE backplane bus redundancy ensures uninterrupted communication with the controller. The HMI displays real-time temperature trend curves (last 24 hours) of each measurement point, and historical data is stored in the Predix cloud platform for analyzing the aging trend of rotor windings.

A 5MW steam turbine (driving a catalytic fan) in a petrochemical catalytic cracking unit requires temperature monitoring of:

- Blades (16 points, PT100 3-wire, normal ≤350℃, early warning ≤380℃, interlock ≤400℃);

- Bearings (4 points, PT100 3-wire, normal ≤90℃, interlock ≤110℃).

The module is required to operate in a catalytic workshop environment with high dust and strong electromagnetic interference (near frequency converters) and support communication with the DCS system (Siemens S7-1500).

- Blade Temperature Monitoring and Interlock: 16 channels monitor blade temperature, with "multi-channel AND logic" configured (interlock triggered when 2+ blades have temperature >400℃) to avoid false shutdowns caused by single-blade temperature measurement errors. Upon over-temperature, it immediately cuts off the steam inlet valve and uploads the interlock signal to the DCS.

- Interference Resistance and Protection: The module is installed in a control cabinet ≥2m away from frequency converters; input cables use shielded twisted pairs (single-end grounding of the shield layer) to resist electromagnetic interference. IP20 protection prevents dust in the catalytic workshop from entering terminals, ensuring good channel contact.

- DCS Communication: An optional Modbus TCP interface uploads blade and bearing temperature data (update frequency 1s) to the S7-1500 PLC. The DCS interface displays the temperature and interlock status of each measurement point, and the DCS links with audible and visual alarms upon over-temperature.

A small turbine (simulating core components of aircraft engines) in an aircraft engine ground test bench requires temperature monitoring of:

- Rotor (4 points, PT1000 4-wire, normal ≤600℃, interlock ≤650℃);

- Combustion chamber wall (8 points, PT100 3-wire, normal ≤800℃, interlock ≤850℃).

The module is required to operate in a test bench environment with high shock (startup/shutdown shock ≤30g) and wide temperature range (-10℃ to 65℃), and support high-speed sampling and data recording.

- High-Speed Sampling and Data Recording: The sampling rate is set to 100 samples/second to capture rapid temperature changes during turbine startup/shutdown (e.g., combustion chamber wall temperature rising from 20℃ to 800℃ in only 30s). It internally stores 1000 over-temperature records (including timestamps and temperature values) that are retained even after power-off, for analyzing temperature peaks during tests.

- High Shock Adaptability: The 30g shock resistance design resists mechanical shock during test bench startup/shutdown. Components inside the module are fixed with anti-vibration glue to prevent solder joint detachment caused by shock.

- Safety Interlock: When combustion chamber wall temperature >850℃, it triggers "test bench emergency shutdown"

![]()