Description

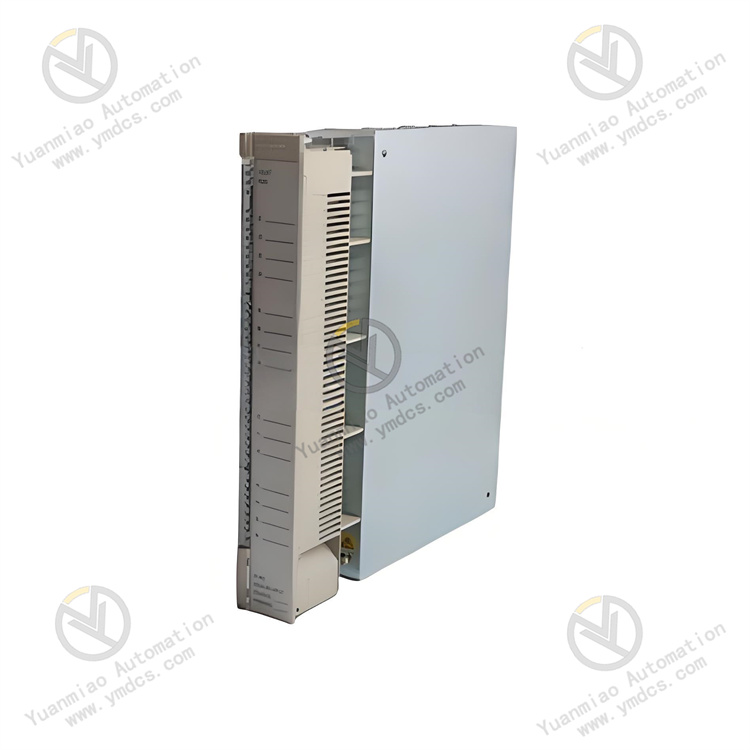

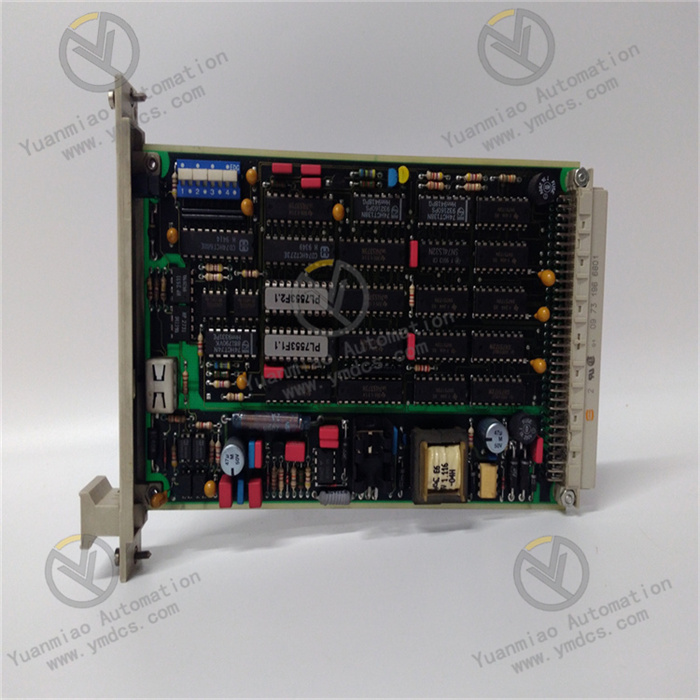

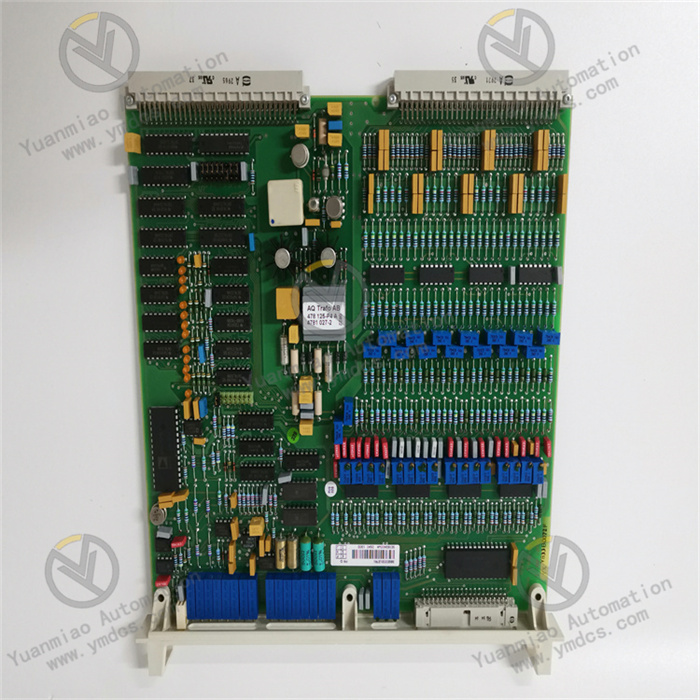

The Honeywell 51308307 - 175 is the input/output terminal component CC - TCNT01 of the Honeywell C300 controller. Functional Features Signal Processing and Transmission: It can achieve direct peer-to-peer communication with other logic managers, process managers, and advanced process managers. It can also fully communicate with operators, engineers, and maintenance personnel of general workstations. By communicating with application modules and hosts on the local control network, it supports higher-level strategies. Communication Protocol: It supports standard Modbus communication, facilitating data interaction with other devices or systems that support this protocol. Environmental Adaptability: It has a wide working temperature range. It can operate without derating between -10°C and +50°C, and can withstand up to +60°C. All components are coated, enabling it to adapt to various harsh environments. Safety and Reliability: It has excellent quality. The components are designed for a 10-year service life. It has a super braking capacity and can reach 70% of the rated torque of the motor without a braking resistor. It also supports the safety torque shutdown function (SIL3), ensuring safety in critical applications. Configuration and Startup: It can be quickly started without the need for settings. Parameter settings can be carried out without powering on while it is still in the packaging. It is also equipped with application macros and a panel assistant, which facilitates quick debugging and reduces installation time and errors.

Technical Parameters Rated Current: 0.311A at 24V DC. Frequency Support: It supports frequencies of up to 599Hz and is suitable for induction motors and permanent magnet motors. Dimensions: 125mm×105mm×30mm. Weight: Approximately 0.22kg. Connection Type: It has an optimized design, making it easy to integrate with various control systems. Common Faults and Solutions Communication Fault: It may be caused by a loose communication interface, incorrect communication parameter settings, or electromagnetic interference. Check whether the interface connection is firm, confirm that the communication parameters match those of other devices in the system, and check for strong interference sources around. Take measures such as shielding and filtering. Module Overheating: It may be due to an excessively high working environment temperature or an overload of the module. Improve the heat dissipation conditions, ensure that the module is installed in a well-ventilated position, and check whether the load exceeds the rated value of the module. Adjust the load if there is an overload. Abnormal Output Signal: It may be caused by a fault in the internal signal processing circuit of the module or incorrect output wiring. Check whether the output wiring is correct and firm. If the wiring is normal, contact professional maintenance personnel for inspection or module replacement.

Application Cases

Industrial Automation Production Lines: In automation production lines such as automotive manufacturing and electronic device production, it connects various sensors (such as position sensors and temperature sensors) and actuators (such as motors and robotic arms). It collects various data during the production process and controls the actions of the actuators according to the preset logic, realizing the automated control of the production process and quality monitoring.

Chemical Process Control: In the control systems of equipment such as reaction kettles and distillation columns in chemical production, it can collect parameters such as temperature, pressure, and flow rate in real time. These parameters are transmitted to the controller for analysis and processing through this module, and then it controls the operation of devices such as valves and pumps, ensuring the safety, stability, and efficiency of the chemical production process.

Power System Monitoring: In power systems such as substations and power plants, it connects with electrical quantity sensors (such as voltage transformers and current transformers) and switching equipment (such as circuit breakers and isolating switches). It collects the operating parameters of the power system, enabling remote control of the switching equipment and real-time monitoring and protection of the power system.