Description

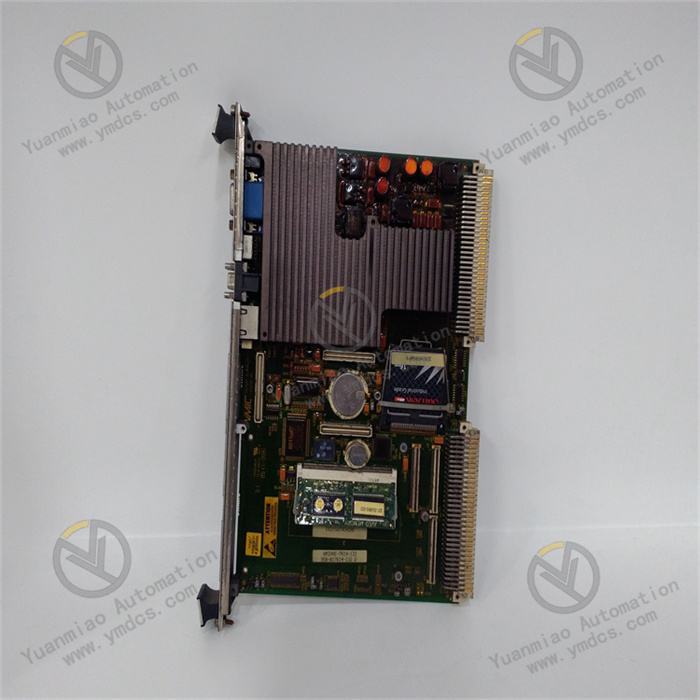

Functional Purpose It is usually used as a part of complex control systems for the control, monitoring, and data processing of various industrial equipment and processes. For example, in the automated control systems of fields such as power systems, manufacturing production lines, and petrochemicals, it may undertake important tasks such as control logic operations, signal transmission and conversion, and equipment status monitoring. Technical Characteristics High Reliability: It adopts high-quality electronic components and advanced manufacturing processes, and can operate stably in harsh industrial environments. It has characteristics such as anti-interference, anti-vibration, and high-temperature resistance to ensure the reliable operation of the system for a long time. Powerful Processing Capacity: It may be equipped with high-performance microprocessors or digital signal processors (DSPs), which can quickly process a large number of input and output signals, implement complex control algorithms and logical operations, and meet the requirements for real-time performance and accuracy in industrial production processes. Rich Interfaces: It has various types of interfaces, such as digital input and output interfaces (DI/DO), analog input and output interfaces (AI/AO), and communication interfaces (such as Ethernet, serial port, Profibus, etc.), which can be conveniently connected and communicate with other devices to achieve system integration and expansion.

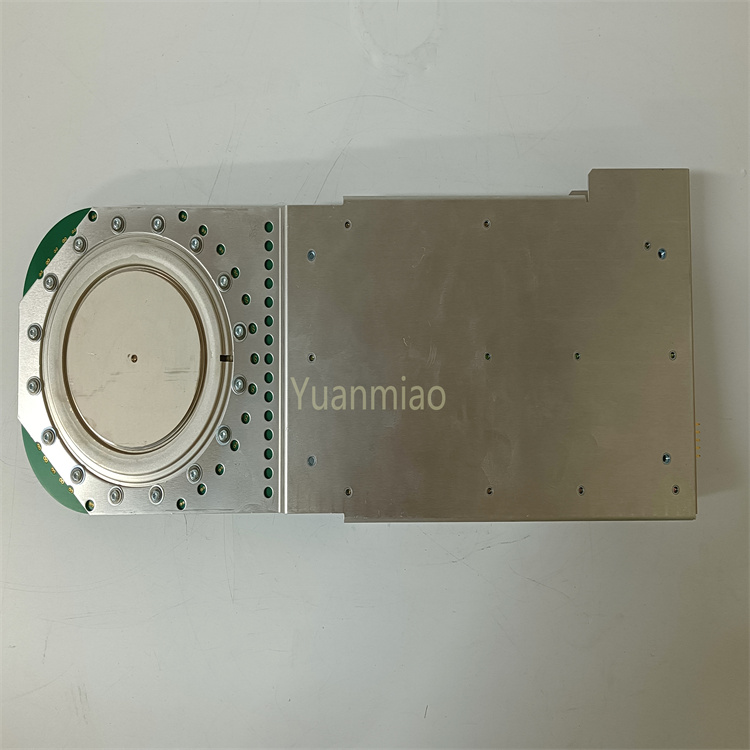

Technical Parameters: Input Types: Voltage, current. Input Range: Voltage is ±10V, ±5V, ±2.5V, ±1V, ±0.5V; current is ±20mA, ±10mA, ±5mA, ±2mA, ±1mA. Accuracy: 0.05%. Resolution: 12 bits. Sampling Rate: 1kHz. Isolation: 2kV. Protection Level: IP67. Dimensions: 100 mm × 70 mm × 30 mm. Weight: 0.5 kg. Processor: Intel Pentium 133MHz. Memory: 32MB DRAM, 16MB Compact Flash. Ethernet Interface: Follows the Ethernet Global Data (EGD) protocol. COM Ports: 3 (COM1, COM2, and 9-pin D-type connector), baud rate 19200. Operating System: A preemptive multitasking operating system based on the QNX platform. Operating Temperature: Inlet air temperature 0°C - 45°C. Storage Temperature: -40°C - 85°C. Humidity: 10% - 95% relative humidity, without condensation. Cooling Method: Forced air cooling. Power Requirements: 5V DC (6A - 8A max), 12V DC (180mA - 250mA max).

Operation Guide for GE IS215UCVEH2AE: Hardware Installation Preparation Work: Prepare the required tools, such as a screwdriver. Ensure that the relevant power supply is cut off before operation, and take anti-static measures, such as wearing an anti-static wrist strap, to avoid damage to the module caused by static electricity. Module Installation: Install the IS215UCVEH2AE module on the corresponding VME card rack, ensure that the module is aligned with the slots of the card rack, then gently insert and fix it, and tighten the fixing screws on the panel. Cable Connection: According to the actual application requirements, connect the input signal cables to the corresponding input ports of the module, ensuring that the connection is firm and the signal types, polarities, etc. match. At the same time, connect other relevant communication cables, power cables, etc., and ensure good grounding to reduce electromagnetic interference.

Software Configuration Driver Installation: If this is the first time to use the module, the corresponding driver needs to be installed. Usually, you can download the latest driver suitable for your operating system from the official GE website, then run the installation program and complete the driver installation according to the prompts. After the installation is completed, it may be necessary to restart the computer to make the driver effective. Module Parameter Configuration: Open the relevant configuration software (the specific software name may vary depending on the system). In the software, find and select the IS215UCVEH2AE module for configuration. According to the type of the actually connected sensor and the measurement requirements, set parameters such as the input type (such as voltage, current), input range, sampling rate, etc. Other relevant parameters, such as filtering parameters and alarm thresholds, can also be configured as needed. Communication Parameter Setting: If the module needs to communicate with other devices, such as data interaction with the host control system or other modules, the corresponding communication parameters, such as communication protocol, address, baud rate, etc., need to be configured to ensure the normal operation of communication.

Operation and Monitoring

System Startup: After completing the hardware installation and software configuration, turn on the power supply and start the relevant control system and monitoring software.

Data Monitoring and Analysis: Through the monitoring software, you can view the data collected by the module in real time, including information such as the values and statuses of the input signals. Analyze the collected data to determine whether it meets the expectations and whether there are any abnormal situations.

Fault Diagnosis and Handling: If there are faults or abnormalities during operation, such as inaccurate data collection or communication interruption, first check whether the hardware connection is loose and whether the cables are damaged, and then check whether the software configuration parameters are correct. You can refer to the user manual or technical documents of the module for fault diagnosis and troubleshooting. If the problem persists, it may be necessary to contact GE's technical support personnel for assistance.

Maintenance and Upkeep Regular Inspection: Regularly check the operation status of the module, including checking whether the hardware connection is firm and whether there are abnormal phenomena such as overheating and strange odors in the module. At the same time, check whether the parameter settings in the software have changed and whether the data collection is normal. Module Cleaning: Regularly clean the dust and dirt on the surface of the module, and gently wipe it with a clean soft cloth. Avoid using cleaning agents containing corrosive substances to prevent damage to the module. Configuration Backup: Regularly back up the configuration file of the module to prevent the loss or damage of the configuration. In this way, when it is necessary to reconfigure the module, it can be quickly restored to the previous normal configuration state.