Description

GE 531X307LTBAJG1

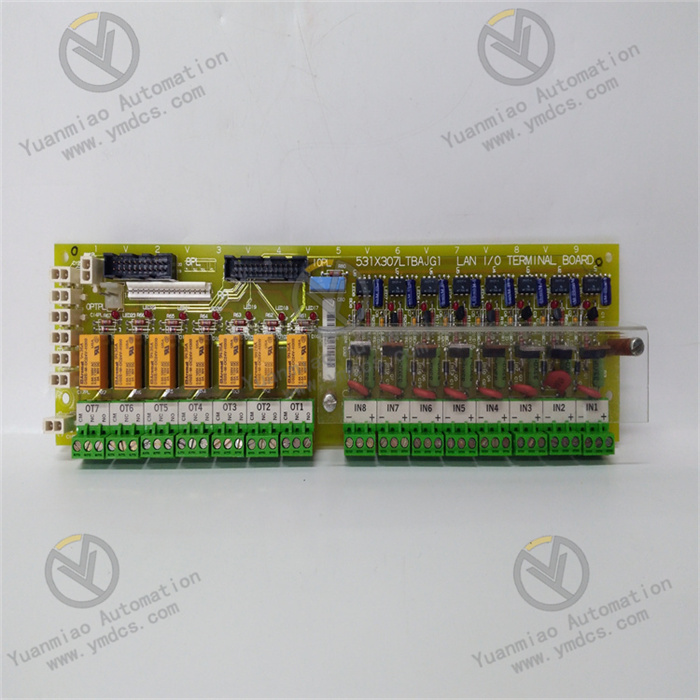

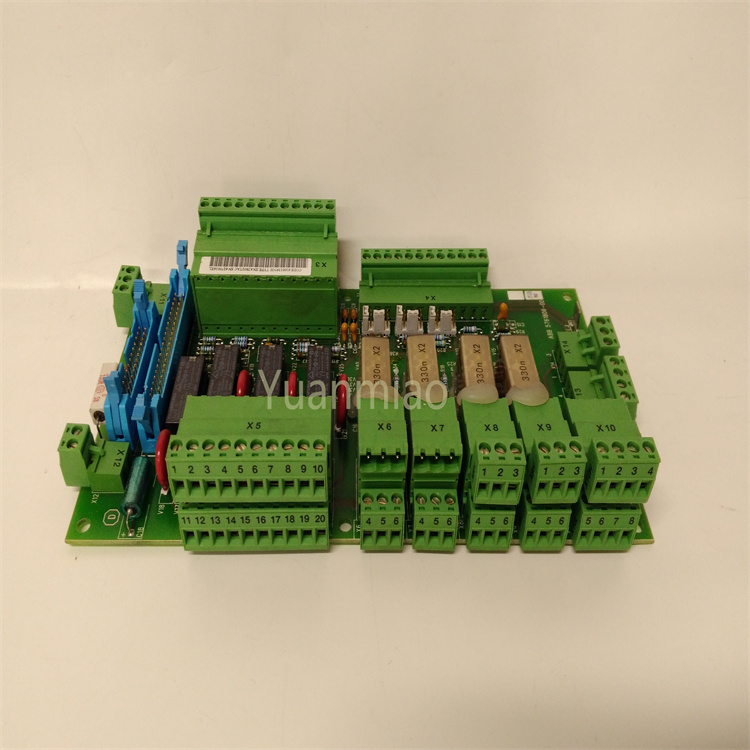

The GE 531X307LTBAJG1 is a high-performance industrial control Local Area Network (LAN) terminal board, belonging to the 531X series replacement board family. It is specifically designed for industrial control systems in local area network (LAN) environments. As a key component of GE's automation solutions, this terminal board primarily serves as an interface bridge between drives and exciters. It supports the reliable connection of external devices such as interlocking devices, buttons, and indicator lights, while enabling efficient LAN signal distribution.

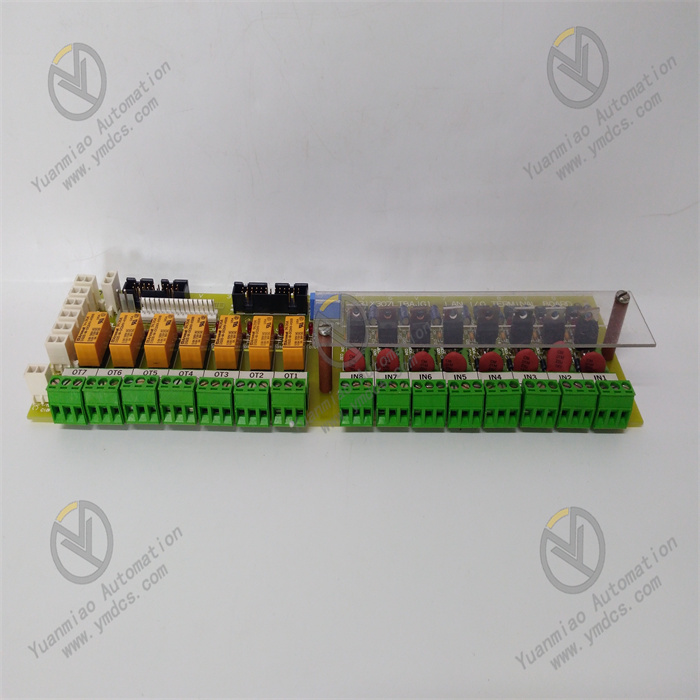

This terminal board adopts a modular design concept, optimized in accordance with "Six Sigma" quality standards. It features plug-and-play functionality and visual fault diagnosis capabilities, allowing seamless integration into existing GE series drives and exciter systems. Its compact structural design and flexible configuration capabilities make it a critical component for connecting the control layer and equipment layer in the field of industrial automation, widely used in industries such as manufacturing, power systems, and process control.

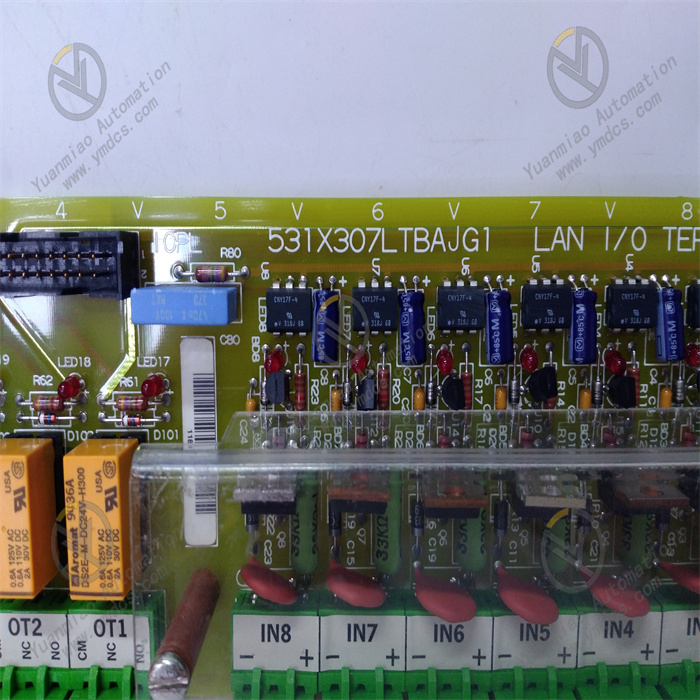

- Interface Configuration: Provides 8 configurable 24VDC control input sockets (IN 1-IN 8), supporting flexible connection of external sensors and control devices; equipped with 7 sets of Form C relay contact outputs, each set containing 3 terminals, supporting low-voltage and low-current control signal output.

- Communication Capability: As a LAN I/O terminal card, it supports industrial LAN signal transmission and is compatible with mainstream fieldbus protocols such as DeviceNet and PROFIBUS, enabling real-time data interaction with upper-level control systems.

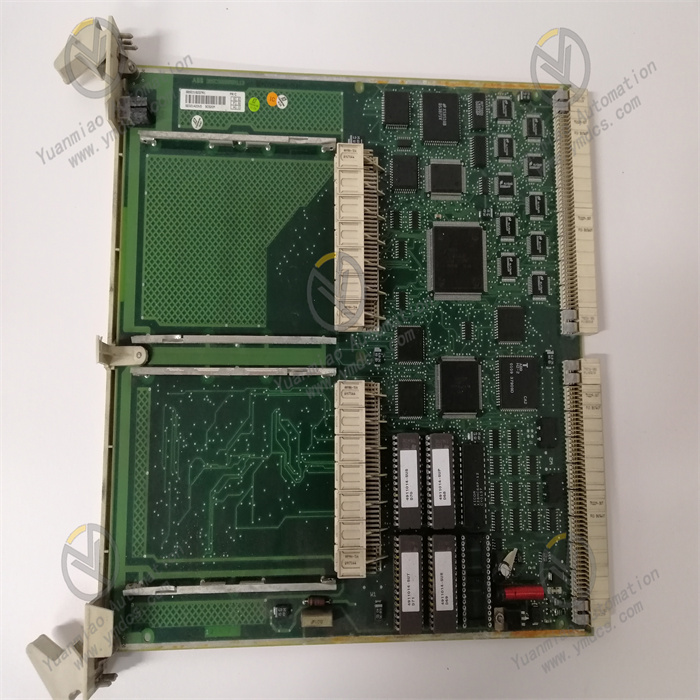

- Compatibility: Specifically designed for GE series drives and exciters, it can be used as a replacement board for the 531X series. It forms a complementary interface solution with other modules in the same series (e.g., 531X307LTBAKG1, 531X307LTBAFG1).

- Dimensions and Weight: Physical dimensions are 11.25×3.25×1.00 inches (approximately 286×83×25 mm), with a weight of only 0.3kg, suitable for installation in compact spaces.

- Installation Method: Supports modular installation, no special tools are required for expansion, and it can be seamlessly integrated with VersaMax PLC systems and I/O modules.

- Environmental Adaptability: Adopts an industrial-grade design, capable of stable operation under typical industrial environment conditions (specific temperature and humidity ranges are not clearly specified, but it complies with GE's general standards for industrial products).

- Input Voltage: 24VDC control input, compatible with industrial standard sensor signals.

- Output Characteristics: 7 sets of high-voltage and high-current relays are activated through pilot contact connections. When used in conjunction with the RTBA board, full access to the relay contacts can be achieved.

The most prominent feature of this terminal board is its design of 8 configurable input channels. Users can flexibly define the type of input signals according to on-site requirements, and adapt to different types of sensors and control buttons without replacing hardware. This flexibility greatly reduces inventory costs and the difficulty of system upgrades, making it particularly suitable for industrial environments with a variety of equipment types.

It has a built-in efficient LAN signal distribution platform and adopts an enhanced electromagnetic compatibility design, ensuring stable and reliable signal transmission even in industrial environments with strong electromagnetic interference. The relay outputs use an isolation design, effectively preventing the impact of external voltage fluctuations on the control system.

It supports plug-and-play functionality, no professional tools are required for module installation and replacement, significantly shortening system deployment and maintenance time. Equipped with visual status indicators and fault diagnosis functions, it facilitates quick location of interface faults and improves system availability.

As a compatible component of the VersaMax PLC system, it can be used to build a distributed control system with a maximum of 256 points, and can also be used as a PROFIBUS or DeviceNet slave device. This modular structure enables the system to have good expandability, and the number of control points can be gradually expanded according to production needs.

In manufacturing production lines, this terminal board can serve as an interface hub between the equipment layer and the control layer. It connects devices such as conveyor belt deviation sensors, emergency stop buttons, and indicator lights, transmits real-time status data to the PLC via the LAN network, and receives control commands to drive actuators at the same time. Its compact design is particularly suitable for installation in control cabinets of production lines with limited space.

In the automation systems of power plants and substations, it can be used to connect various sensors and control components of the generator excitation system. It realizes the centralized collection and transmission of exciter status monitoring, parameter adjustment, and fault alarm signals, providing key interface support for the stable operation of power systems.

In process industries such as chemical engineering, petroleum, and pharmaceuticals, this terminal board can be integrated into process control systems. It connects devices such as valve status sensors, pressure switches, and liquid level switches, realizing real-time collection of key production process parameters and accurate distribution of control signals, ensuring stable and controllable production processes.

As a replacement board of the 531X series, this terminal board is an ideal choice for upgrading old industrial control systems. It can directly replace the original interface board, and improve the interface capability and data transmission reliability of the system without large-scale modification of existing wiring and control systems.

- Ensure compatibility with GE series drives and exciters, and verify the matching of equipment models before installation;

- The relay output terminals should be correctly matched with the load capacity to avoid overload use;

- Control input wires should be kept at an appropriate distance from power wires to reduce electromagnetic interference;

- It is recommended to use a single-ended grounding method to connect shielded cables to enhance anti-interference capability.

- Check whether the 24VDC power supply is normal;

- Verify whether the input channel configuration matches the sensor type;

- Check whether the wiring terminals are loose or oxidized.

- Check whether the LAN network connection is normal;

- Verify whether the bus address setting is correct;

- Confirm whether the terminal resistor configuration meets the bus requirements.

- Check whether the power supply for the relay coil is normal;

- Test whether the relay contacts are stuck or damaged;

- Confirm that the load current does not exceed the rated value.

- Check whether the module is installed in place;

- Verify the compatibility settings with the controller;

- Try reinserting the module or restarting the control system.

As a LAN terminal board specifically designed for industrial control environments, the GE 531X307LTBAJG1, with its flexible configuration capabilities, reliable signal transmission, and convenient integration features, has become a key interface component for connecting on-site equipment and control systems. Its modular design not only simplifies the system construction process but also provides convenience for future expansion, making it particularly suitable for various application scenarios such as industrial automation, power monitoring, and process control.

Compared with products such as the GE 8502-BI-DP digital input module, this terminal board focuses more on signal distribution and interface expansion in LAN network environments. The two complement each other in GE's automation solutions, jointly building a complete link from signal collection to data transmission. For users who need to upgrade existing control systems or build new industrial networks, the GE 531X307LTBAJG1 provides an interface solution with both cost-effectiveness and reliability.

![]()