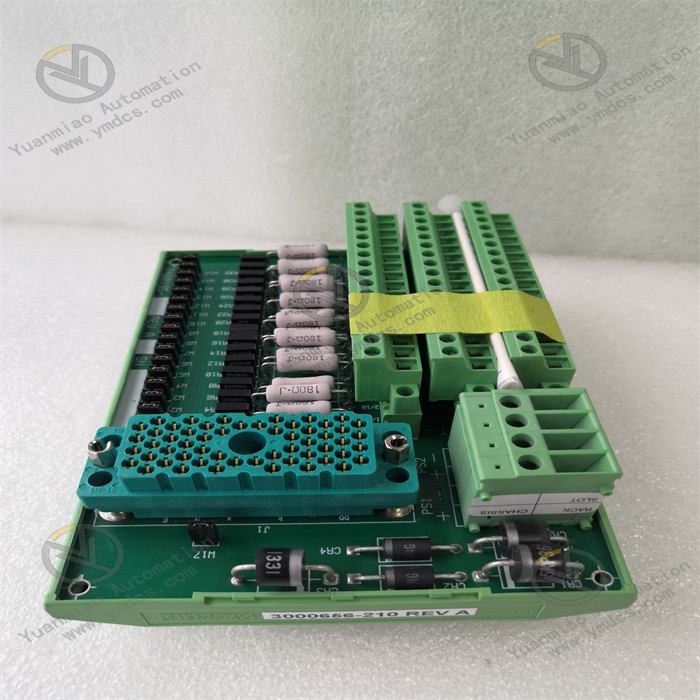

Description

GE 8851-LC-MT

The GE 8851-LC-MT is a high-performance SafetyNet safety controller specifically designed for industrial safety-critical control systems. As a core member of the GE 8000 Series I/O module family, it adopts a 32-bit RISC processor architecture, enabling stable operation of safety control programs and real-time monitoring and rapid response to potential risks in the production process. This controller not only supports high-speed communication with up to 64 I/O modules but also builds a multi-level industrial communication network through dual redundant Ethernet and serial interfaces, providing a reliable safety assurance solution for high-risk industries such as petrochemicals and electric power.

Its unique redundant design can be configured into a master-standby mode, and when combined with the non-disturbance switching function, it significantly improves system availability. Even in extreme environments such as Class 1, Div 2 hazardous areas, the hardware architecture certified by SIL 2 (Safety Integrity Level 2) and the comprehensive diagnostic mechanism can still ensure the continuous effectiveness of safety functions. As a core component of the industrial automation safety layer, the GE 8851-LC-MT perfectly connects on-site equipment with upper-level management systems, serving as a key hub for process safety management.

- Processor and Memory: Equipped with a high-performance 32-bit RISC processor, along with dedicated RAM and flash memory for program storage and data processing, ensuring efficient operation of complex safety algorithms.

- Communication Capability:

- Dual high-speed fault-tolerant redundant Ethernet, supporting industrial standard protocols.

- Serial communication interface supporting asynchronous transmission rates ranging from 1.2 to 115.2 kbits/s.

- Built-in rail bus, capable of connecting up to 64 I/O modules to achieve point-to-point communication.

- Safety Certification: Certified to SIL 2 Safety Integrity Level, compliant with FM and CSA Class 1, Div 2, Grps A, B, C, D T4 hazardous area standards, and adopting EEx nL IIC T4 protection technology.

- Power Requirements: Requires 12VDC power supply from the 8913-PS-AC power module, with a typical operating current of 0.4A, a maximum current of 0.5A, and a maximum system power consumption of 15mA.

- Dimensions and Weight: Physical dimensions are 69mm (width) × 232mm (length) × 138mm (height), weighing approximately 1.35kg. Its compact design is suitable for dense installation in control cabinets.

- Environmental Adaptability: Operating temperature range from -40℃ to +70℃, storage temperature range from -40℃ to +85℃, capable of adapting to harsh industrial on-site environments.

- Redundancy Configuration: Supports master-standby mode (1oo1d) redundancy configuration, enabling automatic synchronization and non-disturbance switching without additional software.

- Installation Compatibility: Must be installed on a dedicated 8751-CA-NS carrier, supporting seamless integration with 8811-IO-DC digital modules and 8810-HI-TX analog modules (with HART function).

- Event Logging: Built-in event log function, capable of storing up to 8,000 system events, providing complete data support for fault tracing.

The GE 8851-LC-MT adopts hardware-level safety design. The 1oo1d architecture certified by SIL 2, combined with a comprehensive internal diagnostic mechanism, ensures the integrity of safety functions. In hazardous area applications, its special circuit design and isolation technology (Ethernet isolation with a withstand voltage of 1500V) effectively prevent safety hazards caused by electric sparks, meeting the strict requirements of explosion-proof environments. The controller can monitor its own operating status in real-time, and once an abnormality is detected, it immediately triggers a safety response to minimize system risks.

The redundancy function of this controller does not require complex configuration. After inserting a new standby controller into the carrier slot, the system will automatically complete program synchronization and activation of redundancy algorithms. The master-standby switching process achieves non-disturbance transition, ensuring no interruption of safety control functions. This design is crucial for continuous production processes, as it can maintain system stability even in the event of a controller failure, avoiding losses caused by unplanned downtime.

With the support of dual redundant Ethernet and multiple protocols, the GE 8851-LC-MT can communicate simultaneously with operation stations, HMIs (Human-Machine Interfaces), historian systems, and asset management tools. Its rail bus technology enables high-speed data exchange with I/O modules, while the HART pass-through function allows parameter configuration and diagnosis of on-site instruments without interrupting safety control, greatly improving maintenance convenience. This multi-level communication architecture enables the controller to not only serve as the core of safety control but also realize information interaction with process control systems.

Support for online configuration and hot-swap operation is an important advantage of this controller. Maintenance personnel can replace modules or modify parameters while the system is in operation, without stopping the production process. The intuitive programming tools and plug-and-play expansion method reduce the difficulty of system debugging. The event log function automatically records all key operations and fault information, and when combined with HART device diagnostic data, forms a complete fault diagnosis system, significantly shortening the fault troubleshooting time.

The protective measures specifically designed for Class 1, Div 2 hazardous areas allow the controller to be directly installed in potentially explosive environments without the need for additional explosion-proof enclosures. Its wide-temperature design and anti-vibration performance ensure stable operation in high-temperature, dusty, and humid industrial environments, making it particularly suitable for safety control needs in industries such as petrochemicals and fine chemicals.

In the Emergency Shutdown Systems (ESD) of oil refineries and chemical plants, the GE 8851-LC-MT acts as the core controller, monitoring key process parameters (pressure, temperature, liquid level, etc.). When an abnormal condition exceeding the safety threshold is detected, it can trigger the emergency shutdown procedure within milliseconds. Its hazardous area certification and redundant design ensure reliable safety control in flammable and explosive environments, preventing major accidents such as leaks and explosions.

In the Furnace Safety Supervision System (FSSS) of thermal power plants, this controller is responsible for monitoring key parameters such as furnace pressure and flame status, and executing safety interlock functions such as fuel cutoff. The redundant Ethernet design enables it to exchange data with the Distributed Control System (DCS), maintaining the independence of the safety layer while realizing the sharing of process information, thus improving the safety and controllability of unit operation.

For the safety control of key equipment such as compressors and desulfurization units in natural gas processing plants, the GE 8851-LC-MT can be used to build a Safety Instrumented System (SIS). Its wide range of environmental adaptability and explosion-proof characteristics allow it to work reliably in harsh outdoor environments and potentially explosive gas environments. By precisely controlling equipment such as valves and pumps, it prevents dangerous situations such as overpressure and leaks.

In the pharmaceutical industry, which has extremely high requirements for production environments, this controller can be used for safety isolation control between clean areas and hazardous areas. Through precise interlock logic, it prevents cross-contamination and safety accidents. The feature of supporting online maintenance allows system upgrades and fault handling without interrupting production, meeting the requirements for continuous and stable pharmaceutical production.

- Loose connection or damage to the Ethernet cable.

- Incorrect redundancy configuration parameters leading to master-standby communication failure.

- Faulty network switch or improper port configuration.

- Check and reinsert the Ethernet cable, and use a tester to verify the integrity of the line.

- Log in to the configuration tool to check the redundancy synchronization status, and ensure that the IP addresses and subnet masks of the master and standby controllers are set correctly.

- Replace the faulty switch port or upgrade the switch firmware, and ensure that the communication rate matches the controller (100Mbps full-duplex is recommended).

- The standby controller has not completed program synchronization.

- Poor contact of the carrier slot.

- Unstable output voltage of the power module.

- Check the controller status indicator lights to confirm that the standby module is in the "synchronization ready" state; if necessary, re-download the program.

- Turn off the system power, reinsert the controller, and clean the slot contacts.

- Use a multimeter to detect the output voltage of the 8913-PS-AC, ensuring that the 12VDC fluctuation does not exceed ±5%; replace the power module if necessary.

- Incorrect configuration of the rail bus terminal resistor.

- I/O module address conflict.

- The cable length exceeds the maximum transmission distance (≤100 meters is recommended).

- Confirm that 75Ω terminal resistors are installed at both ends of the bus, and no resistors should be installed at intermediate nodes.

- Use the configuration tool to check the addresses of all I/O modules and ensure their uniqueness.

- Shorten the bus cable length or add a repeater to reduce signal attenuation.

- Frequent minor faults in the system leading to rapid filling of the log.

- The log has not been exported and cleaned up regularly.

- Abnormality in the controller memory.

- Analyze the root cause of frequently occurring events and solve them targeted (e.g., loose terminal blocks).

- Establish a maintenance system for regular log export, and clear historical records through the configuration tool.

- If the log grows abnormally, check whether the operating temperature of the controller is too high (≤60℃ is recommended); replace the controller module if necessary.

- Incorrect configuration of the safety logic program.

- Input signal interference leading to false triggering.

- Fault in the diagnostic circuit.

- Verify the safety logic program offline, focusing on checking the interlock conditions and delay settings.

- Check whether the sensor wiring is parallel to the power cable; add a shielding layer and ground it at one end.

- Enter the diagnostic mode to run the self-test program; if a hardware fault code is found, contact GE technical support to replace the controller.

![]()