Description

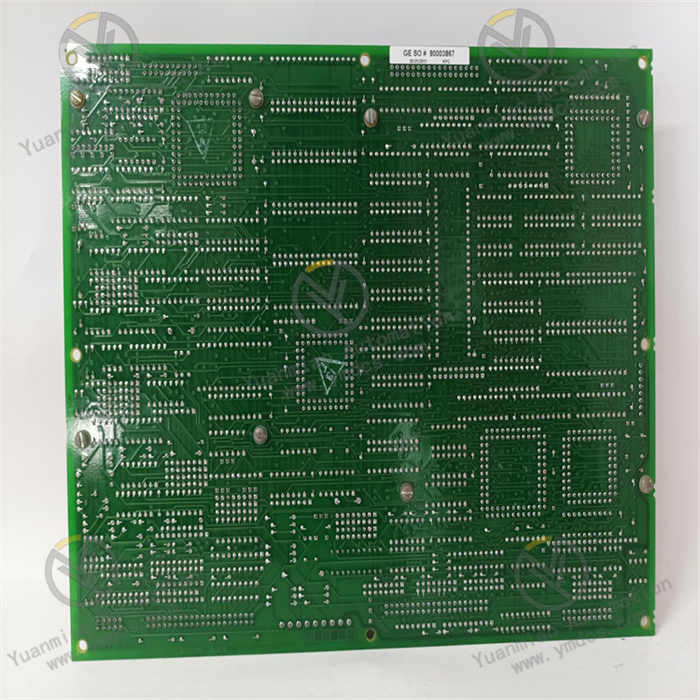

GE IS200TDBTH6ABC

The GE IS200TDBTH6ABC is a temperature signal processing and acquisition module, with its core positioning as the "industrial temperature monitoring center - multi-type sensor adaptation unit - temperature data interface for Mark series controllers". Its core function is to receive signals from multiple types of temperature sensors such as thermocouples (TC) and resistance temperature detectors (RTD) in large industrial equipment (e.g., gas turbines, boilers, compressor units) in power generation, oil and gas, chemical, and other fields. Through high-precision signal conditioning, isolated amplification, and digital conversion, it converts analog temperature signals into standard data that meets the requirements of control systems, and transmits the data to the Mark VI/VIe Speedtronic control system or EX2100 excitation regulator. It provides "high-precision, high-stability, high-isolation" temperature data support for equipment temperature monitoring, fault early warning, and process optimization. Meanwhile, through hardware-level fault diagnosis and anti-interference design, it ensures reliable temperature data acquisition under extreme working conditions, making it a key sensing component for ensuring "controllable temperature and safe operation" of industrial equipment.

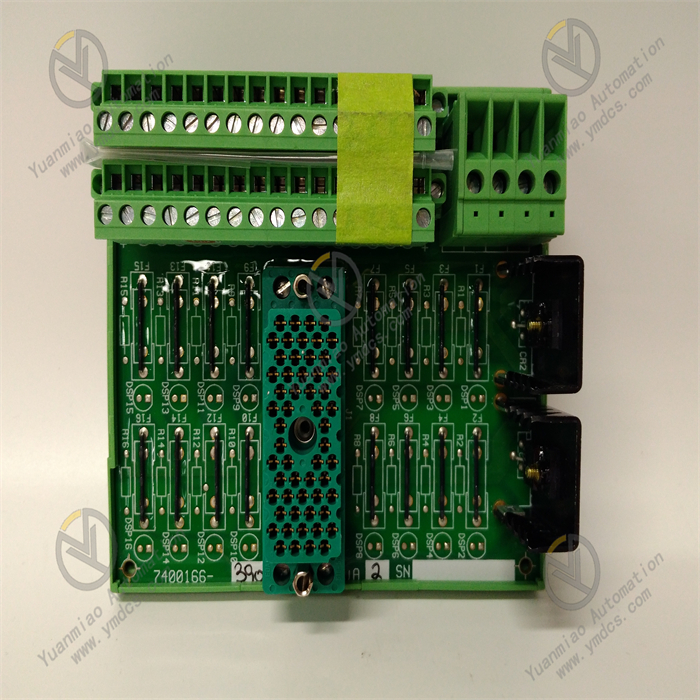

This module has core advantages of "multi-sensor adaptation - ultra-high precision - strong anti-interference": it supports 6 independent temperature signal input channels, is compatible with J/K/T type thermocouples and Pt100/Pt1000 RTDs, and is suitable for different temperature measurement scenarios; the temperature measurement accuracy reaches ±0.1°C (at 25°C), meeting the needs of precision temperature control; it features dual electrical isolation between input and output as well as between channels (isolation voltage ≥500V AC), which completely blocks interference transmission; its industrial-grade hardware design can withstand a wide temperature range of -20°C to 60°C, high humidity, and vibration environments. It is widely used in scenarios such as boiler wall temperature monitoring in thermal power plants, gas turbine bearing temperature acquisition, and petrochemical reactor temperature monitoring, and is a core component for realizing "accurate temperature perception and early risk prediction" of industrial equipment.

The core advantage of the IS200TDBTH6ABC lies in its "6 independent channels + multi-type sensor compatibility" design, which solves the pain point of "coexistence of multiple measurement points and multiple sensor types" in industrial scenarios. In the boiler wall temperature monitoring of a 600MW unit in a thermal power plant, K-type thermocouples are required for the boiler water wall (temperature 300-400°C), and Pt100 RTDs are required for the superheater tube wall (temperature 500-600°C). The 6 channels of the module can be configured separately: 3 channels connected to K-type thermocouples for water wall monitoring, and 3 channels connected to Pt100 for superheater monitoring, without the need for additional module replacement or transfer equipment. At the same time, it supports 3-wire/4-wire RTD wiring (4-wire for high-precision measurement points), ensuring that the superheater temperature measurement accuracy is ≤±0.3°C, which meets the safety requirement of boiler wall temperature deviation ≤±5°C and avoids the risk of tube wall bursting caused by local overheating.

The module adopts high-precision AD conversion and built-in cold-junction compensation, solving the problems of "cold-junction drift and insufficient precision" in thermocouple temperature measurement. In the gas turbine bearing temperature monitoring, the bearing temperature (normal 60-80°C, alarm threshold 100°C) needs to be accurately monitored to avoid bearing burnout accidents. The module performs linearization processing on the J-type thermocouple signal (compliant with IEC 60584 standard) and is equipped with a built-in Pt100 cold-junction compensation sensor (accuracy ±0.1°C), which eliminates the impact of ambient temperature changes on the cold junction. The bearing temperature measurement error is ≤±0.2°C. Meanwhile, the resolution of 0.01°C can capture small temperature fluctuations (e.g., 0.5°C temperature rise), providing an early warning of bearing lubrication abnormalities 10-15 minutes in advance, and avoiding early warning delays caused by errors in traditional modules (accuracy ±0.5°C).

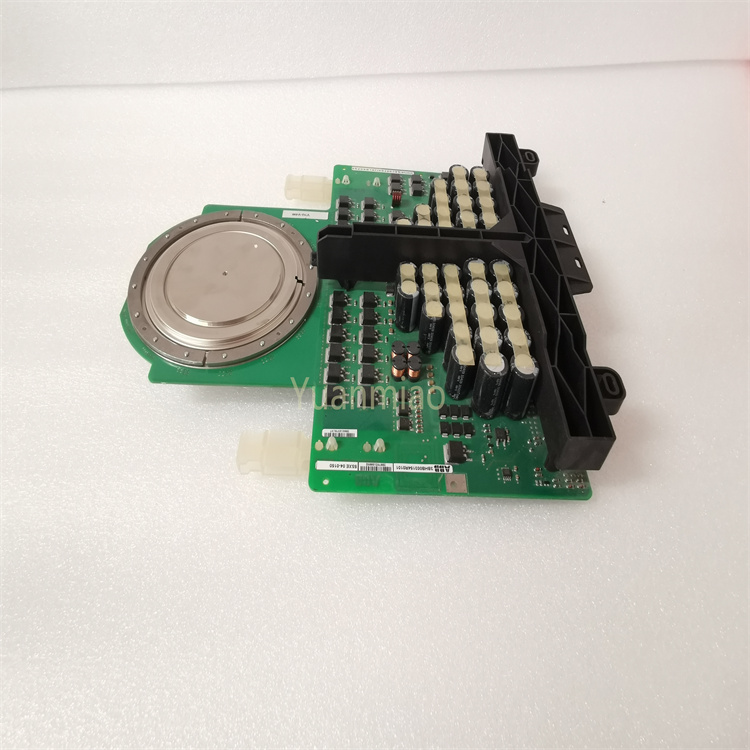

The module features a dual isolation design between input-output and between channels, solving the problems of "signal crosstalk and data distortion" in strong interference environments. In the temperature monitoring of a hydrogenation reactor in a petrochemical plant, there are high-voltage frequency converters and high-power motors around the reactor (electromagnetic radiation intensity up to 20V/m). The 500V AC isolation design blocks interference from transmitting to the measurement channels, and the independent filtering circuit for each channel (cutoff frequency 5Hz) filters out high-frequency interference. The fluctuation of the reactor bed temperature (200-300°C) data collected by the Pt100 RTD is ≤±0.1°C, avoiding temperature false alarms (e.g., false over-temperature alarms) caused by interference. In high-humidity chemical workshops (90% RH humidity), the PCB moisture-proof coating and sealed interfaces prevent moisture intrusion, allowing the module to operate continuously for 6 years without performance degradation, and the data acquisition accuracy reaches 99.99%.

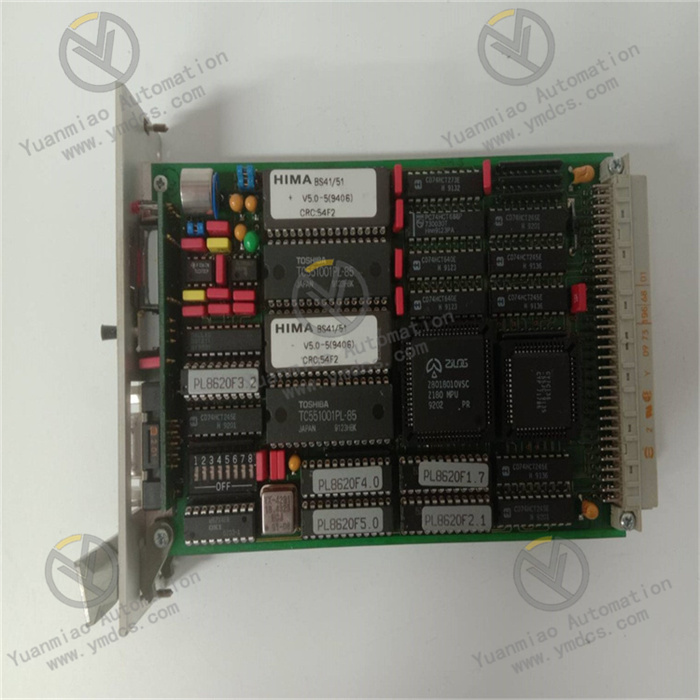

The module supports Ethernet remote communication and software calibration, solving the problems of "difficult on-site O&M and high calibration costs". In the temperature monitoring of compressor units in natural gas processing plants in remote areas, O&M personnel do not need to conduct on-site inspections. They can remotely view the temperature data of 6 channels (e.g., compressor cylinder temperature 120-150°C) and sensor status (e.g., whether it is open) through the GE Calibration Studio software. When the measurement deviation of a Pt100 sensor exceeds ±0.5%, a calibration command is remotely issued via software (inputting a standard resistance value of 100Ω corresponding to 0°C), without the need to disassemble the module or replace the sensor. The calibration time is reduced from the traditional 2 hours to 15 minutes. At the same time, the automatic fault diagnosis function (e.g., immediately uploading a fault code when the sensor is short-circuited) allows O&M personnel to quickly locate problems, reducing the average fault handling time by 60%.

The module's wide temperature design and multi-system compatibility solve the problems of "difficult adaptation to extreme environments and complex system integration". In the temperature monitoring of outdoor wind power box transformers in northern winter (-20°C), the module starts without delay in cold conditions, and the temperature acquisition accuracy has no deviation (the error of J-type thermocouple for measuring box transformer oil temperature is ≤±0.3°C), without the need for additional heating equipment. In the renovation of control systems in old factories, the original system uses a Siemens S7-300 PLC. After adding the IS200TDBTH6ABC, it can be directly connected via the RS485 interface (Modbus-RTU protocol) without replacing the PLC or adding signal conversion modules, reducing integration costs by 30%. At the same time, it supports seamless connection with the Mark VIe system, and the data refresh rate of 10Hz meets the needs of real-time monitoring, adapting to the data integration requirements of Industry 4.0.

- Temperature Data Monitoring: Check the temperature data of 6 channels through the control system HMI daily to confirm that the measured values are consistent with process expectations (e.g., boiler water wall temperature 350-380°C), with no abnormal jumps or fault alarms; check the module indicator lights (power light: green, steady on; running light: green, blinking; fault light: red, off).

- Physical and Wiring Inspection: Check the module's installation screws weekly (torque 0.6-0.8N・m) to avoid loosening caused by vibration; clean the dust on the module surface and interfaces with a dry brush, focusing on checking the sensor wiring terminals (thermocouple positive and negative poles, RTD 3/4-wire wiring) to ensure no looseness or oxidation (oxidized terminals can be slightly polished with sandpaper).

- Accuracy Verification: Use a standard resistance box (simulating Pt100 signal) or thermocouple calibration furnace monthly to verify the accuracy of 1-2 key channels (e.g., inputting 100Ω corresponding to 0°C, the module's measured value should be within the range of 0±0.1°C); if the deviation exceeds the threshold, correct it through remote software calibration.

- Communication and Isolation Inspection: Test the stability of RS485/Ethernet communication quarterly (use Modbus debugging tools to read temperature data and confirm no packet loss); check the isolation performance (measure the insulation resistance between input and output with an insulation resistance tester, which should be ≥100MΩ) to avoid interference caused by isolation failure.

- Environment Adaptation: Measure the module surface temperature with an infrared thermometer every six months (should be <50°C during normal operation); strengthen cabinet ventilation (air speed ≥1m/s) in high-temperature seasons (ambient temperature exceeding 45°C); install dehumidifiers in high-humidity environments to avoid PCB coating failure caused by condensation.

![]()