Description

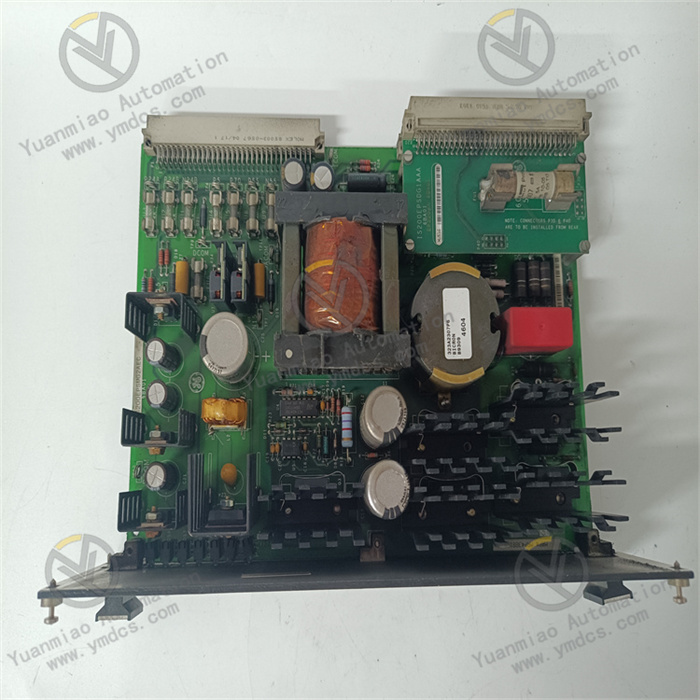

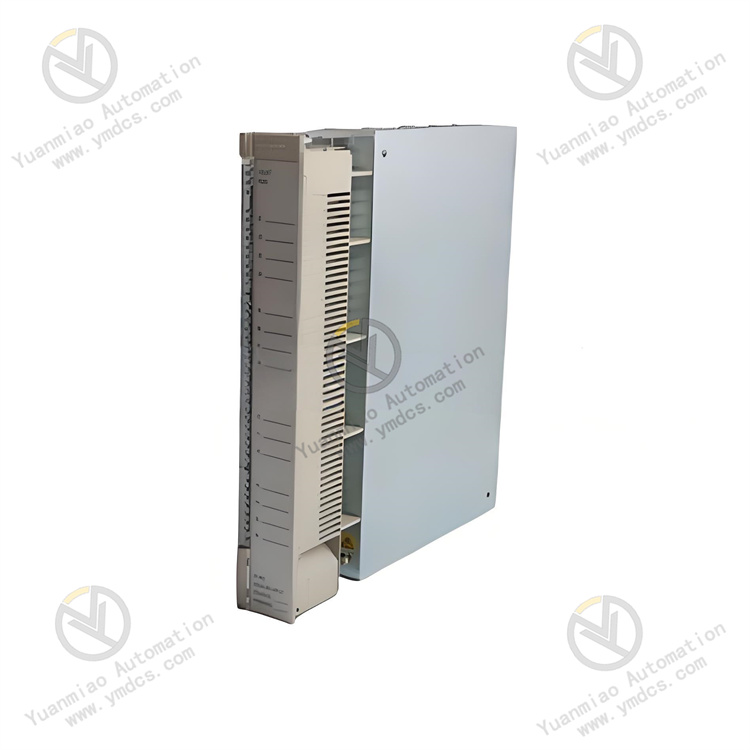

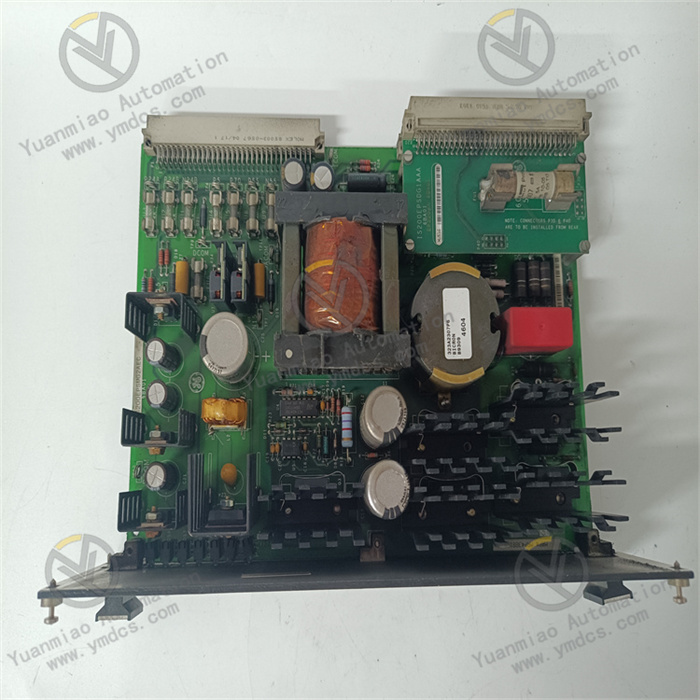

GE IS200EPSMG2AEC

The GE IS200EPSMG2AEC is a dedicated high-redundancy power conversion module for excitation control systems, with its core positioning as the "dual-backup power supply hub of the excitation system - multi-component power support unit - redundant power interface for Mark series controllers". Its core function is to work in deep synergy with dual-redundancy EPDM power modules (such as the IS200EPDMG2A) in the excitation systems of large gas/steam turbines in power generation, oil and gas, energy, and other fields. Through a "dual-input - dual-output" redundant architecture, it accurately converts the input power into isolated voltage levels that meet the requirements of various core components of the excitation system, providing "uninterrupted, high-isolation" power supply for the EX2100 excitation regulator, the triple-redundancy M1/M2/C controllers of the Mark VIe system, and key peripheral modules such as EDCD and EDEX. At the same time, through hardware-level fault self-diagnosis and rapid switching design, it ensures that the excitation system can still operate stably under a single-point fault, making it a "highly reliable power core" that guarantees the accuracy of excitation regulation and continuous power supply for equipment.

This module has core advantages of "full redundancy architecture - ultra-high isolation - strong environmental adaptability": it adopts a design of dual 125VDC main inputs and dual 24VDC/70VDC outputs, with a redundancy switching time of ≤50ms; it features dual electrical isolation between input and output as well as between output channels, with an isolation voltage of ≥1000V AC (upgraded from 500V AC), which completely blocks the transmission of strong interference; its industrial-grade hardware design can withstand an ultra-wide temperature range of -25°C to 60°C, high humidity, and strong vibration environments, and has obtained CE, UL, and IEC 61508 SIL 2 functional safety certifications; it is deeply compatible with the Mark VIe high-redundancy control system and compatible with new and old excitation components of the same series, enabling redundancy upgrades without system reconstruction. It is widely used in safety-critical scenarios such as generator excitation systems of 1000MW-level thermal power units, control units of large gas turbine combined cycle power plants, and excitation circuits of ultra-large petrochemical compressor units, and is a key support for realizing "zero excitation interruption and zero power supply risk" of industrial power equipment.

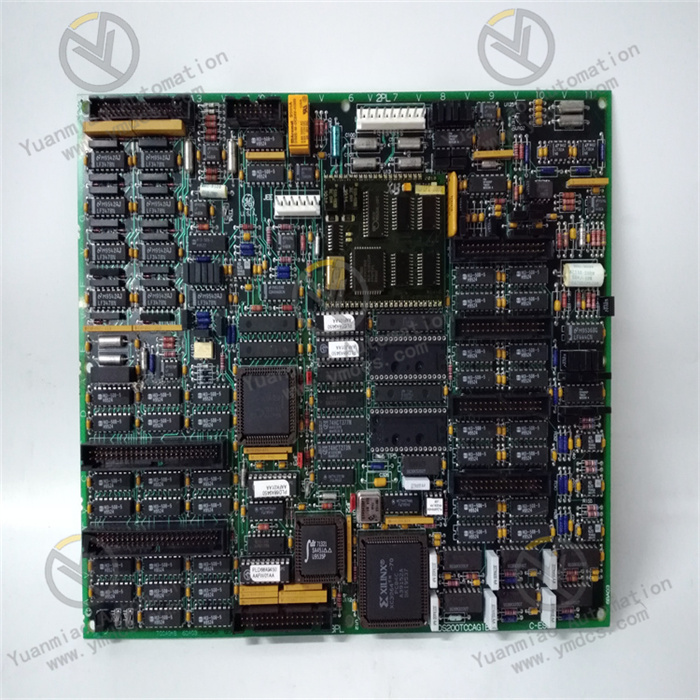

The core advantage of the IS200EPSMG2AEC lies in its "dual-input - dual-output - dual-conversion unit" full redundancy design, which completely solves the pain point of "shutdown caused by single-point power failure" in the excitation system. In the EX2100 excitation system of a 1000MW-level ultra-supercritical thermal power unit, the module connects to two EPDM power supplies (main IS200EPDMG2A, backup IS200EPDMG2B), and the dual conversion units convert 125VDC into 24VDC respectively to supply the main/backup power terminals of the M1 controller. When the main EPDM module fails or the main conversion unit malfunctions, the module automatically switches to the backup channel within 30ms, with the 24VDC output voltage fluctuation ≤±0.1V, and the M1 controller has no restart or data loss. At the same time, the dual-channel 70VDC output ensures the EXTB contact wetting circuit is not interrupted, and the excitation regulation commands are issued normally, avoiding unit tripping due to power supply failure (the shutdown risk was 100% when the traditional single-power module failed, and it is reduced to 0% after upgrading).

The module's isolation voltage is increased to 1000V AC and ripple noise is significantly reduced, solving the problems of "signal drift and reduced regulation accuracy" in strong interference environments. In the Mark VIe system of a large gas turbine combined cycle power plant, there are strong interference sources such as high-voltage frequency converters and generators (electromagnetic radiation intensity up to 30V/m): the 1000V AC isolation design blocks interference from transmitting to the 24VDC control circuit, increasing the signal-to-noise ratio of the excitation current signal collected by the EDCD3A module by 50%; the 24VDC output ripple is ≤30mVpp, reducing the calculation error of the M1 controller from ±0.3% to ±0.1%, and optimizing the gas turbine speed regulation accuracy to ±1rpm, which meets the strict requirements for frequency stability in grid-connected power generation (±0.05Hz).

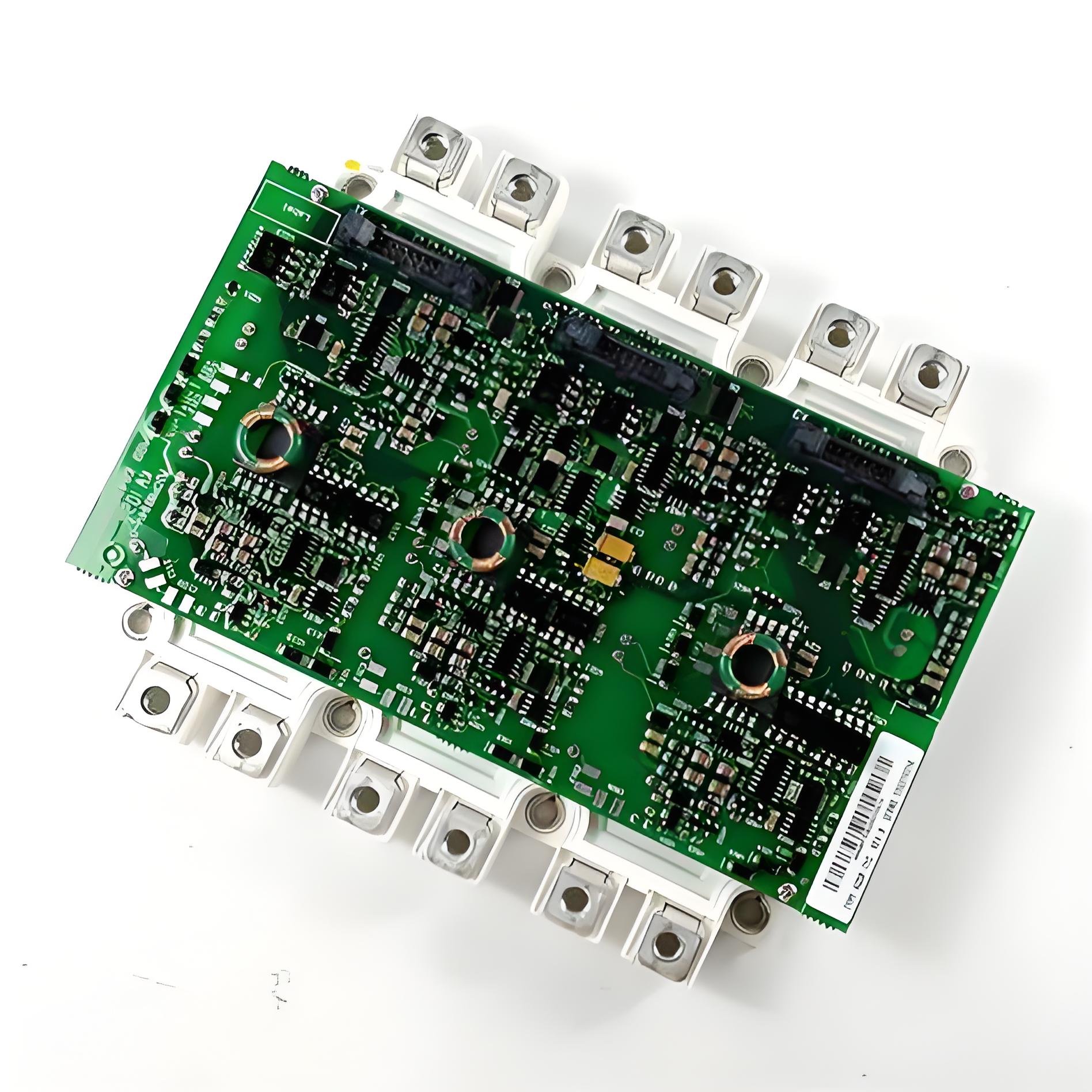

The module has been fully upgraded in temperature and humidity resistance, as well as vibration and shock resistance, enabling it to cope with more complex industrial scenarios. In thermal power plants in cold northern areas in winter (-25°C), the module's cold startup time is ≤80ms, and the 24VDC output accuracy has no deviation (within ±0.12V) without the need for additional heating equipment (traditional modules require heating at -20°C, increasing energy consumption by 30%); in coastal petrochemical plants with high salt spray (95% RH humidity), the nano-level moisture-proof coating and aluminum alloy housing resist salt spray erosion, allowing the module to operate continuously for 8 years without circuit corrosion; in the excitation system of blast furnace fans in metallurgical plants (vibration 30m/s²), the built-in multi-directional vibration damping structure ensures the stability of the conversion unit, with the output voltage fluctuation ≤±0.2V, avoiding regulation abnormalities caused by vibration.

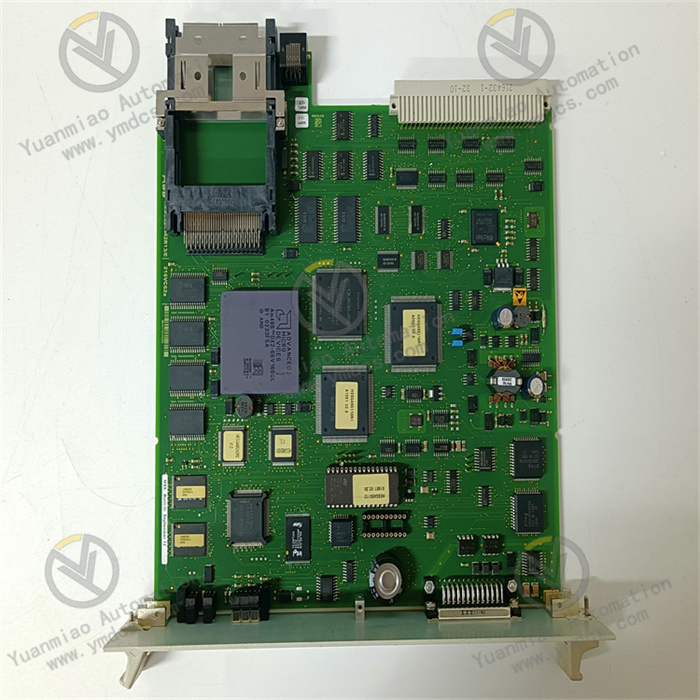

The module adds Ethernet communication and high-precision fault location functions, solving the problems of "difficult fault troubleshooting and low O&M efficiency". In the excitation system of ultra-large petrochemical compressor units, the module uploads data such as dual-channel output voltage, current, and internal temperature to the Mark VIe O&M platform through the Profinet RT interface, allowing O&M personnel to grasp the redundancy status through remote monitoring; when a conversion unit overheats (exceeding 70°C), the platform pops up a real-time prompt of "backup conversion unit activated" and pushes the fault location (such as "main conversion chip abnormality"), eliminating the need for on-site disassembly and troubleshooting, and reducing the fault handling time from 1 hour to 15 minutes. At the same time, it supports remote calibration (issuing calibration commands through the platform), enabling accuracy correction without shutdown, and reducing annual O&M costs by 40%.

The module's compatibility with new and old systems and cross-model components solves the problems of "repeated investment and long shutdown time" in excitation system upgrades. In the renovation of the Mark VI system in old thermal power plants, the original system used IS200EPSMG1AED modules and EDCD2A modules. After adding the IS200EPSMG2AEC, there is no need to replace the EDCD2A or M2 controller, and only an additional adapter card is required to achieve redundancy upgrade; the dual-channel output can supply power to both the original single-power equipment and the newly added redundant equipment at the same time, and the system does not shut down during the renovation (using the "online parallel switching" method), reducing the shutdown time from 24 hours in traditional renovations to 1 hour, and significantly reducing production loss (the daily power generation loss of a single unit exceeds 2 million kWh).

- Redundancy Status Monitoring: Check the dual-channel input/output status through the Mark VIe O&M platform daily: the dual-channel 125VDC input voltage should be between 106-144V, the dual-channel 24VDC output should be between 23.88-24.12V, and the number of redundancy switches should be 0 (when there is no fault); check the communication status (both dual RS485 + Ethernet are normal, no packet loss) and fault alarms (no overcurrent, overvoltage, or overheating prompts).

- Physical and Interface Inspection: Check the module's installation screws weekly (torque 0.8-1.0N・m) to avoid loosening caused by vibration; clean the dust in the module's heat dissipation holes and TP test points with dry compressed air (0.2MPa); check the dual-channel EPDM connection wires (125VDC input) and output terminals to ensure no oxidation of the terminals (a copper brush can be used to clean the oxide layer) and consistent tightness of the dual-channel wiring.

- Redundancy Switching Test: Manually trigger the power-off of the main EPDM monthly, observe that the module's switching time to the backup channel is ≤50ms, and the output voltage fluctuation is ≤±0.1V; trigger a fault in the main conversion unit (software simulation), confirm that the backup channel takes over immediately, and the controller does not restart; manually restore the main channel after the test and record the switching process data.

- Accuracy and Environment Monitoring: Measure the dual-channel output voltage through the TP test points with a high-precision multimeter (accuracy ±0.001V) quarterly, and compare it with the platform data; the deviation should be ≤±0.03V; measure the temperature of the dual conversion units with an infrared thermometer (should be <55°C under normal conditions); strengthen cabinet ventilation (air speed ≥1.5m/s) in high-temperature seasons (ambient temperature exceeding 45°C) to avoid triggering overheating protection.

- Software and Calibration: Update the module firmware through the O&M platform every six months (to ensure compatibility with the system version); perform remote accuracy calibration (input standard 125VDC, adjust the output to 24.00V) without on-site disassembly; back up the module configuration parameters (including redundancy strategy and protection threshold) to prevent parameter loss.

![]()