Description

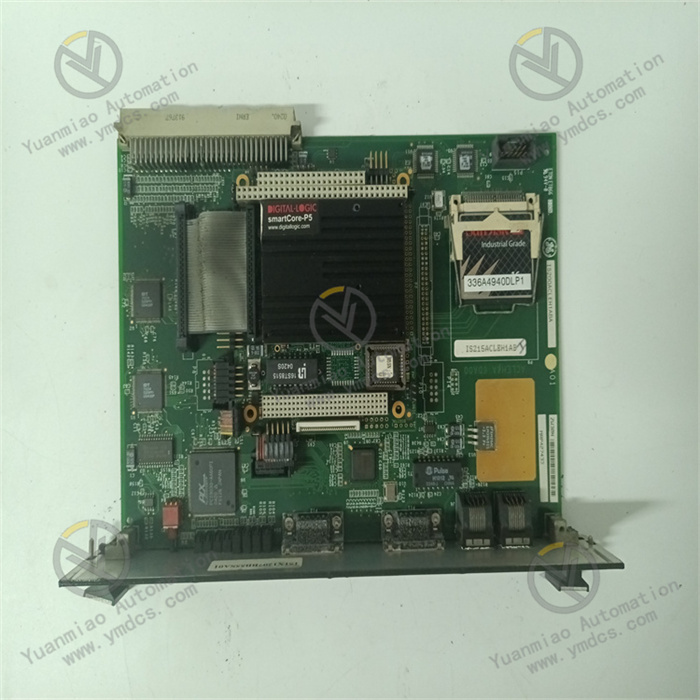

GE IS200ACLEH1ABA

I. Overview

GE IS200ACLEH1ABA is an analog signal conditioning module, with its core positioning as an "analog signal precision conversion hub - system anti-interference isolation unit - industrial equipment collaborative adaptation carrier". Its core function is to receive weak analog signals (voltage/current type) output by industrial on-site sensors (such as temperature, pressure, and flow sensors), convert the signals into standard signals recognizable by the Mark VIe control system through hardware-level signal amplification, filtering, and linearization processing, and at the same time block external interference through electrical isolation, providing accurate and stable data support for the control logic of key equipment such as gas turbines, steam turbines, and wind turbines.

As a key signal processing component of the Mark VIe system, this module has core advantages of "high-precision conditioning - strong anti-interference - modular compatibility":

- It adopts a 16-bit high-precision ADC chip, and the analog signal conversion accuracy reaches ±0.05% Full Scale Range (FSR);

- Triple optoelectronic isolation (isolation voltage ≥2500V AC) is implemented between input/output/power supply to resist strong electromagnetic interference in industrial fields;

- The modular design supports DIN rail installation and hot-swap, and is highly compatible with the Mark VIe distributed control system and GE Speedtronic turbine management system.

Compliant with the IEC 61000-6-2 anti-interference standard and UL industrial safety certification, it is widely used in process control and equipment monitoring scenarios in fields such as electric power, petrochemicals, and new energy, and serves as the "signal preprocessing core" for ensuring the precise regulation of industrial systems.

II. Technical Parameters

1. Basic Specifications

| Item | Parameter Details |

|---|---|

| Equipment Type | Mark VIe series analog signal conditioning module, used for amplification, filtering, and isolation conversion of industrial sensor signals |

| Compatible Systems | GE Mark VIe distributed control system, Speedtronic gas/steam/wind turbine management system |

| Installation Method | DIN rail installation (compatible with 35mm standard rails); compact design; supports hot-swap maintenance |

| Overall Dimensions | Width 45mm × Height 120mm × Depth 110mm (suitable for narrow spaces in control cabinets, with a single module occupying small rail space) |

| Equipment Weight | Approximately 0.3-0.4 kg (lightweight design for easy installation and replacement) |

| Power Supply Requirements | Input voltage: 24V DC ±10% (supports redundant power supply); rated power consumption ≤8W |

| Operating Environment | Temperature: -20°C~65°C (covering industrial high and low temperature scenarios); Humidity: 5%~95% (non-condensing) |

| Protection Design | PCB boards are coated with moisture-proof and anti-corrosion coating; input and output ports have reverse connection protection; shell flame retardant rating: UL94 V-0 |

| Storage Environment | Temperature: -40°C~85°C; Humidity: 5%~95% (non-condensing); supports long-term offline storage and transportation |

2. Core Performance Parameters

Signal Conditioning Characteristics

| Item | Parameter Details |

|---|---|

| Input Signal Types | Compatible with multiple types of analog signals:- Current signals: 4-20mA DC (2-wire/4-wire sensors)- Voltage signals: 0-5V DC, 0-10V DC, 1-5V DC- Resistance signals: RTD (Pt100, Pt1000, supporting 2-wire/3-wire/4-wire connection) |

| Output Signal Types | Standard digital signals (transmitted via Mark VIe backplane bus); optional analog output: 4-20mA DC (load ≤500Ω) |

| Conversion Accuracy | 16-bit ADC conversion; analog signal linear accuracy ±0.05% FSR (within 0-60°C temperature range) |

| Signal Response Time | Time from signal input to stable output ≤10ms (including filtering processing) |

| Filtering Function | Hardware low-pass filtering (cutoff frequency 1kHz) + software-configurable digital filtering (filter constant 1ms-10s), capable of filtering high-frequency noise |

| Linearization Processing | Built-in RTD signal nonlinear correction algorithm; Pt100 signal measurement error ≤±0.2°C (within -200°C~800°C range) |

Isolation and Anti-Interference Characteristics

| Item | Parameter Details |

|---|---|

| Isolation Capacity | Triple optoelectronic isolation between input and output, and between input/output and power supply; isolation voltage ≥2500V AC for 1 minute |

| Anti-Interference Performance | Electrostatic Discharge (ESD): ±8kV contact/±15kV air (compliant with IEC 61000-4-2);Electrical Fast Transient (EFT): ±2kV at power terminals/±1kV at signal terminals (compliant with IEC 61000-4-4);Surge: ±4kV differential mode/±2kV common mode (compliant with IEC 61000-4-5) |

| Electromagnetic Radiation | Compliant with EN 55022 Class B standard; radiation interference ≤54dBμV/m (30MHz-1GHz frequency band) |

Communication and Collaboration Characteristics

| Item | Parameter Details |

|---|---|

| Communication Interface | Built-in dedicated Mark VIe backplane bus interface (rate 100Mbps), supporting real-time communication with the system controller |

| Data Transmission Capacity | Analog signal sampling frequency ≥100Hz; data update cycle ≤10ms |

| Collaboration Capacity | Highly compatible with Mark VIe system configuration software (e.g., ControlST), supporting online configuration and calibration of signal parameters; can be directly connected to GE sensors (e.g., Rosemount pressure transmitters) and actuators |

III. Functional Features

1. High-Precision Signal Conditioning to Ensure the Accuracy of Control Logic

The core advantage of IS200ACLEH1ABA lies in its precise processing capability for weak analog signals, solving the control deviation problem caused by "signal distortion and large errors" in industrial fields. In gas turbine exhaust temperature monitoring, the module receives the resistance signal (corresponding to a temperature range of 0-600°C) output by the Pt100 sensor, corrects the sensor's nonlinear error through a built-in linearization algorithm, converts it into a digital signal via a 16-bit ADC, and finally transmits it to the Mark VIe controller. The temperature error is ≤±0.2°C, ensuring the controller can accurately adjust fuel supply and prevent gas turbine damage due to overheating. For 4-20mA pressure signals (e.g., steam pressure of 0-10MPa), the module removes high-frequency noise (above 1kHz) caused by pipeline vibration through hardware filtering, with signal fluctuation ≤±0.05% FSR, providing stable data support for the steam turbine pressure control logic.

2. Triple Isolation Design to Resist Strong Industrial Interference

In response to strong electromagnetic interference generated by equipment such as frequency converters and high-voltage motors in industrial fields, the module completely blocks the interference transmission path through "input-output-power supply" triple optoelectronic isolation. In the boiler room of a thermal power plant, even with 10kV high-voltage motors nearby, the module can still stably process the furnace temperature sensor signal (0-10V DC) without signal drift or false triggering; the power terminal is equipped with a built-in EMI filter, compliant with the EN 55022 Class B radiation standard, preventing the module itself from causing interference to other equipment. This anti-interference design enables the module to achieve a signal collection accuracy of 99.99% in scenarios with complex electromagnetic environments, much higher than that of ordinary conditioning modules (approximately 99.5%), significantly reducing the risk of equipment misoperation caused by interference.

3. Flexible Configuration and Online Operation & Maintenance to Reduce Management Costs

The module supports full-parameter online configuration through the Mark VIe system configuration software (ControlST) without the need for on-site power-off or equipment disassembly. Maintenance personnel can complete signal type setting (e.g., configuring Channel 1 as 4-20mA current input), filter constant adjustment (e.g., setting 500ms filtering for vibration scenarios), and calibration parameter modification (e.g., correcting sensor offset error) in the central control room. Configuration changes take effect immediately, improving debugging efficiency by more than 60%. At the same time, the module has a built-in self-diagnosis function that can real-time monitor its own circuit status (e.g., ADC chip failure, power undervoltage). Fault information is uploaded to the system HMI via the bus, allowing maintenance personnel to intuitively view the fault type (e.g., "Channel 3 ADC conversion fault") and location, shortening the average fault location time to less than 10 minutes.

4. Modular Compatibility and Redundant Design to Improve System Reliability

As a native component of the Mark VIe series, the module achieves seamless compatibility with system controllers and other I/O modules (e.g., IS200EPSMG1ABB power module), supporting plug-and-play expansion. In the control system of a large wind farm, a single Mark VIe controller can connect 16 IS200ACLEH1ABA modules to achieve centralized conditioning of 64 channels of analog signals (e.g., wind speed, generator temperature, nacelle vibration) without additional protocol conversion equipment. The module also supports 24V DC redundant power supply; when one power supply fails, the other can switch without interruption (switching time <1ms) to ensure uninterrupted signal conditioning. In some scenarios, dual-module hot backup can be configured; when the main module fails, the backup module takes over signal processing within 100ms, meeting the safety requirements of SIL 2 level.

5. Adaptation to Harsh Environments to Extend Service Life

The module adopts full industrial-grade hardware design and protection processing to ensure stable operation in harsh environments. The PCB board is coated with a military-grade conformal coating (moisture-proof, anti-corrosion, dust-proof), enabling a service life of more than 12 years in petrochemical workshops with 95% RH high humidity and oil-gas corrosion scenarios; the wide-temperature design of -20°C~65°C allows it to adapt to outdoor cabinets in northern winter (-15°C) and high-temperature workshops in southern summer (60°C) without additional temperature control equipment; the shell is made of flame-retardant ABS material (UL94 V-0 grade), which self-extinguishes when exposed to fire, meeting industrial fire protection requirements. Through third-party testing, the module operates continuously for 1000 hours in a vibration environment (10-500Hz, acceleration 3g) without hardware damage or performance degradation, fully meeting the long-term operation needs of heavy industrial equipment.

IV. Operation, Maintenance, and Troubleshooting

Daily Maintenance Points

- Status Monitoring: Check the module's operating status through the Mark VIe HMI daily to confirm that the signal values of each channel are within the process allowable range (e.g., pressure 0-10MPa corresponding to 4-20mA) and there are no fault alarms; inspect the module's power indicator (steady green), operation indicator (flashing blue), and fault indicator (off red) on-site to ensure the indicators are in normal status.

- Wiring and Isolation Inspection: Check the wiring of the module's input and output terminals monthly, and re-tighten the screws (torque 0.4-0.6N・m) to prevent wiring looseness caused by vibration (increased contact resistance leading to signal deviation); check the grounding of the signal cable shielding layer (ground resistance ≤4Ω) to ensure anti-interference effect; measure the isolation resistance (≥100MΩ between input and output) to verify the normal isolation performance.

- Regular Calibration: Calibrate key channels (e.g., temperature and pressure control channels) quarterly. Use a standard signal source (e.g., Fluke 726 multifunctional calibrator) to input 0%, 25%, 50%, 75%, and 100% FSR signals, and check whether the module's output signal error is ≤±0.05% FSR. If the error exceeds the limit, correct the calibration parameters online through the ControlST software without disassembling the module.

- Environment and Cleaning: Clean the dust on the module surface and heat dissipation holes weekly (blow along the heat dissipation direction with compressed air); check the installation environment temperature (measure the module surface temperature with an infrared thermometer, which should be <60°C) and humidity (avoid condensation) monthly. For high-temperature and high-humidity scenarios, enhance ventilation or add dehumidification equipment.

Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Solutions |

|---|---|---|

| No signal collection in a certain channel (HMI displays "invalid value") | 1. Sensor cable open circuit or wrong wiring; 2. Fault in signal conditioning circuit; 3. Wrong channel configuration | 1. Measure the sensor output signal (e.g., 4-20mA current) with a multimeter; if there is no signal, repair the sensor or cable; 2. Replace with a spare channel for testing; if the spare channel is normal, the original channel circuit is faulty, and the module needs to be replaced; 3. Verify the channel configuration (e.g., signal type, range) in the ControlST software and reconfigure correct parameters |

| Excessive signal fluctuation (deviation >±0.1% FSR) | 1. Electromagnetic interference; 2. Too small filter constant setting; 3. Loose sensor | 1. Increase the distance between the module and the interference source (e.g., frequency converter) to ≥3m, replace the signal cable with twisted shielded cable and ground it at one end; 2. Increase the filter constant through software (e.g., from 100ms to 500ms); 3. Check whether the sensor is installed firmly and re-fix it to avoid signal fluctuation caused by vibration |

| Module reports "power fault" and power indicator is off | 1. Power supply cable open circuit or reverse polarity connection; 2. Redundant power supply switching fault; 3. Fault in module power circuit | 1. Measure the 24V DC power supply voltage with a multimeter (should be 21.6-26.4V), and check the cable continuity and polarity (avoid reverse connection); 2. Switch to the backup power supply; if the power indicator is on, the original power supply or switching circuit is faulty; 3. If there is still no response when the power supply is normal, replace the module |

| Error still exceeds limit after calibration | 1. Insufficient accuracy of the standard signal source; 2. Fault in the module's ADC chip; 3. Excessive error of the sensor itself | 1. Replace with a standard signal source with higher accuracy (e.g., 0.01% grade) and recalibrate; 2. Replace the module and recalibrate; if the error returns to normal, the original module's ADC is faulty; 3. Detect the sensor error and replace the sensor if the error exceeds the limit |

V. Application Scenarios

- Gas Turbine Exhaust Temperature Monitoring: In the gas turbine system of a combined-cycle power plant, the module receives resistance signals from 4 channels of Pt100 sensors (measuring exhaust temperature of 0-600°C), converts them into digital signals and uploads them to the Mark VIe controller after linearization and filtering; the controller adjusts the fuel valve opening according to the temperature data to ensure the exhaust temperature is stabilized at 580°C±2°C, preventing damage to the gas turbine's hot components. The module's isolation design can resist strong electromagnetic interference around the gas turbine.

- Thermal Power Plant Steam Turbine Pressure Control: In the 600MW steam turbine system, the module conditions 8 channels of pressure transmitter signals (4-20mA corresponding to 0-16MPa steam pressure), removes pipeline vibration noise, and transmits them to the controller; when the pressure exceeds the limit, the controller issues instructions to adjust the control valve. The module's high precision (±0.05% FSR) ensures the pressure control error is ≤±0.08MPa, meeting the safety operation requirements of the steam turbine.

Wind Farm Generator Status Monitoring: In the 2.5MW wind turbine system, the module collects 12 channels of analog signals including generator stator temperature (Pt1000 signal, -40°C~150°C), nacelle vibration (0-10V DC corresponding to 0-50mm/s), and wind speed (4-20mA corresponding to 0-25m/s), and realizes centralized data monitoring through the Mark VIe system; when the temperature exceeds 140°C, load reduction protection is triggered. The module's wide-temperature design is suitable for the outdoor environment of -20°C~65°C.

- Petrochemical Plant Reactor Level Control: In the chemical batch reactor system, the module conditions the level transmitter signal (4-20mA corresponding to 0-5m level), filters it, and transmits it to the DCS system; the system controls the feed pump according to the level data. The module's anti-interference capability ensures stable signal collection even around frequency converters, with a level control accuracy of ±0.025m, avoiding reactor overflow or dry burning accidents.